Product closed end bending, chamfering and angle shoveling die

A closed-end, product technology, applied in the field of stamping dies, can solve problems such as affecting appearance, affecting assembly, and related parts separation, and achieves the effect of convenient and quick demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below with reference to the drawings and embodiments.

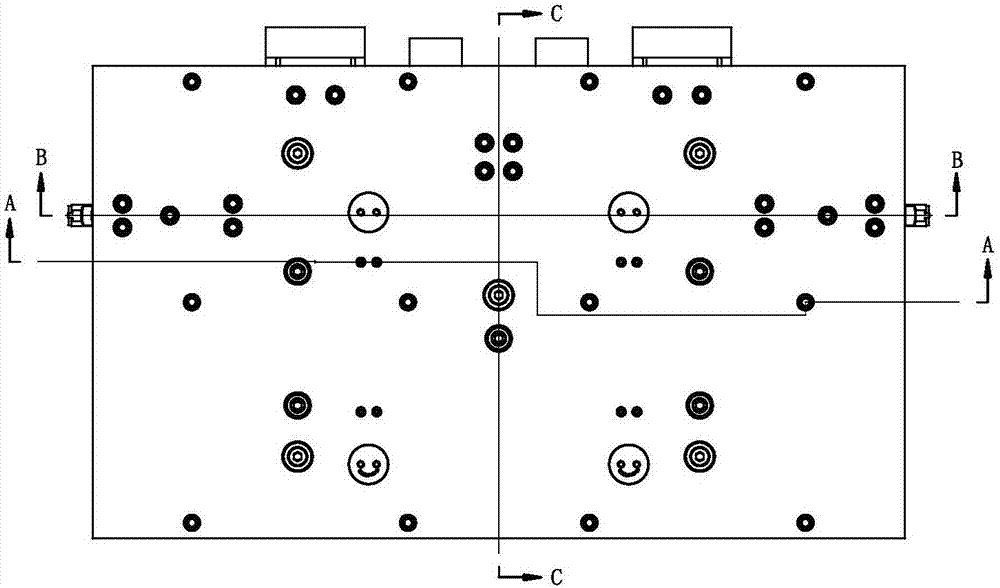

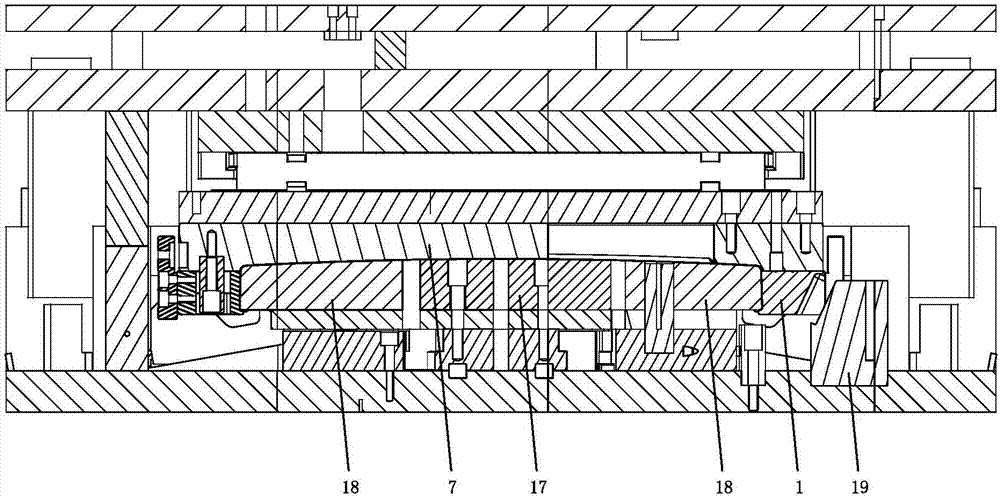

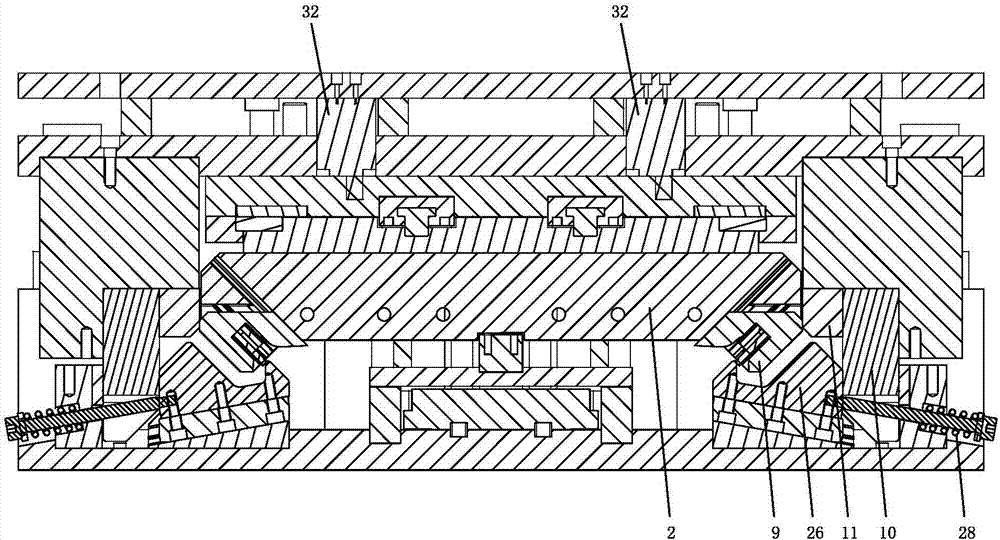

[0049] See Figure 1-Figure 26 , The closed-end folding and shovel corner mold of this product is mainly used for processing refrigerator door panels, specifically to bend the edge of the refrigerator door panel to generate flanging d1, first corner d2 and second corner d3. The mold includes an upper mold assembly and a lower mold assembly corresponding to each other up and down; a pressing mechanism and an end folding mechanism are arranged between the upper mold assembly and the lower mold assembly; the specific structures are as follows:

[0050] The pressing mechanism includes a driving punch 17, two side pressing punches 18, two side pressing plates 1, a sliding plate 22, a first upper wedge 6 and a first lower wedge 23, and the two side pressing punches 18 are respectively arranged on the driving punch On both sides of 17, the pressing plates 1 on both sides are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com