Intelligent wave generating water channel with active feedback wave elimination function

An active and active elimination technology, which is applied in fluid dynamics test, machine/structural component test, measuring device, etc., can solve the difficulty of achieving high-precision and high-quality target waves, and the difficulty of achieving high-quality waves. Eliminate problems such as reflected waves in real time, achieve high application value and promotion value, rich and varied swing forms, and easy to achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

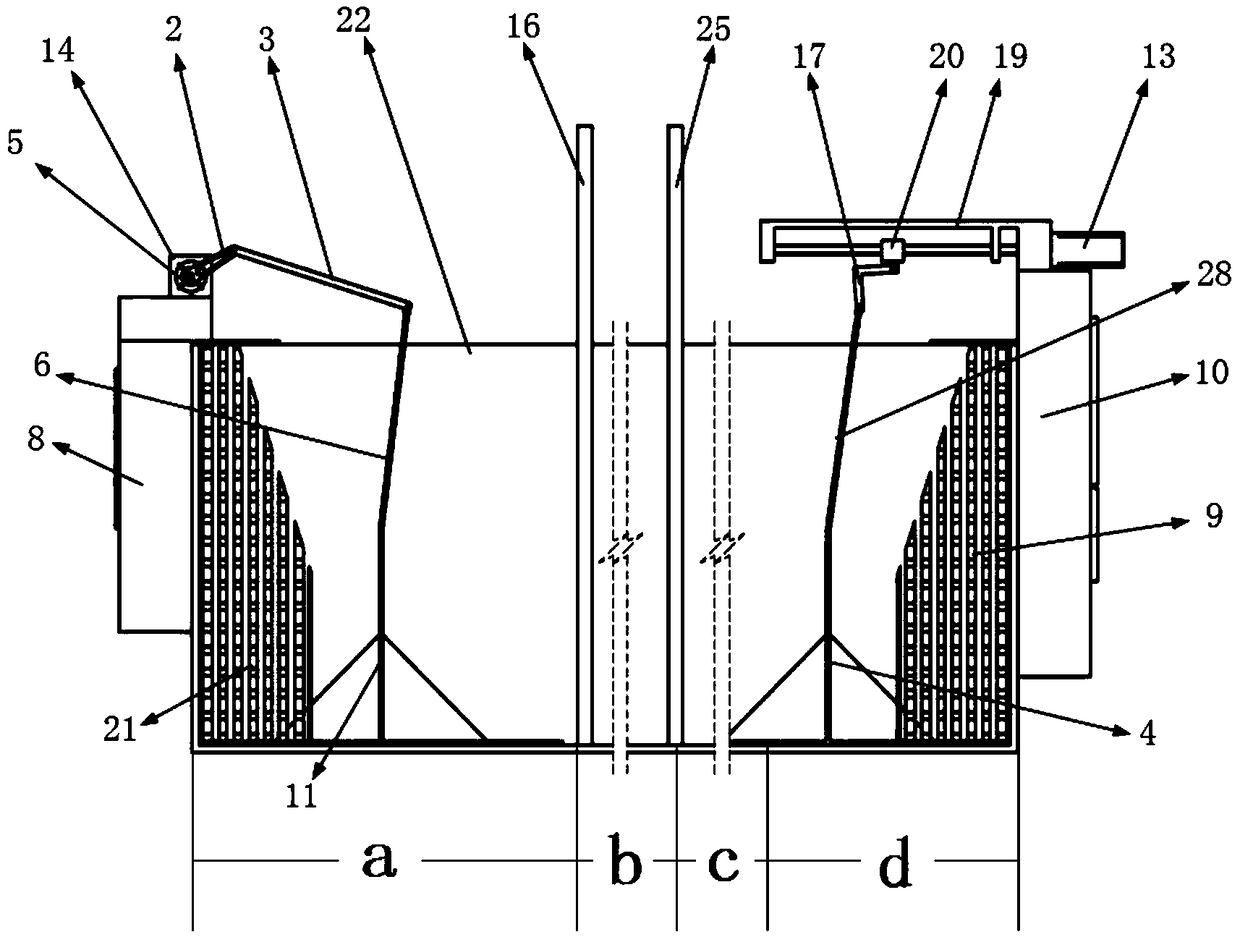

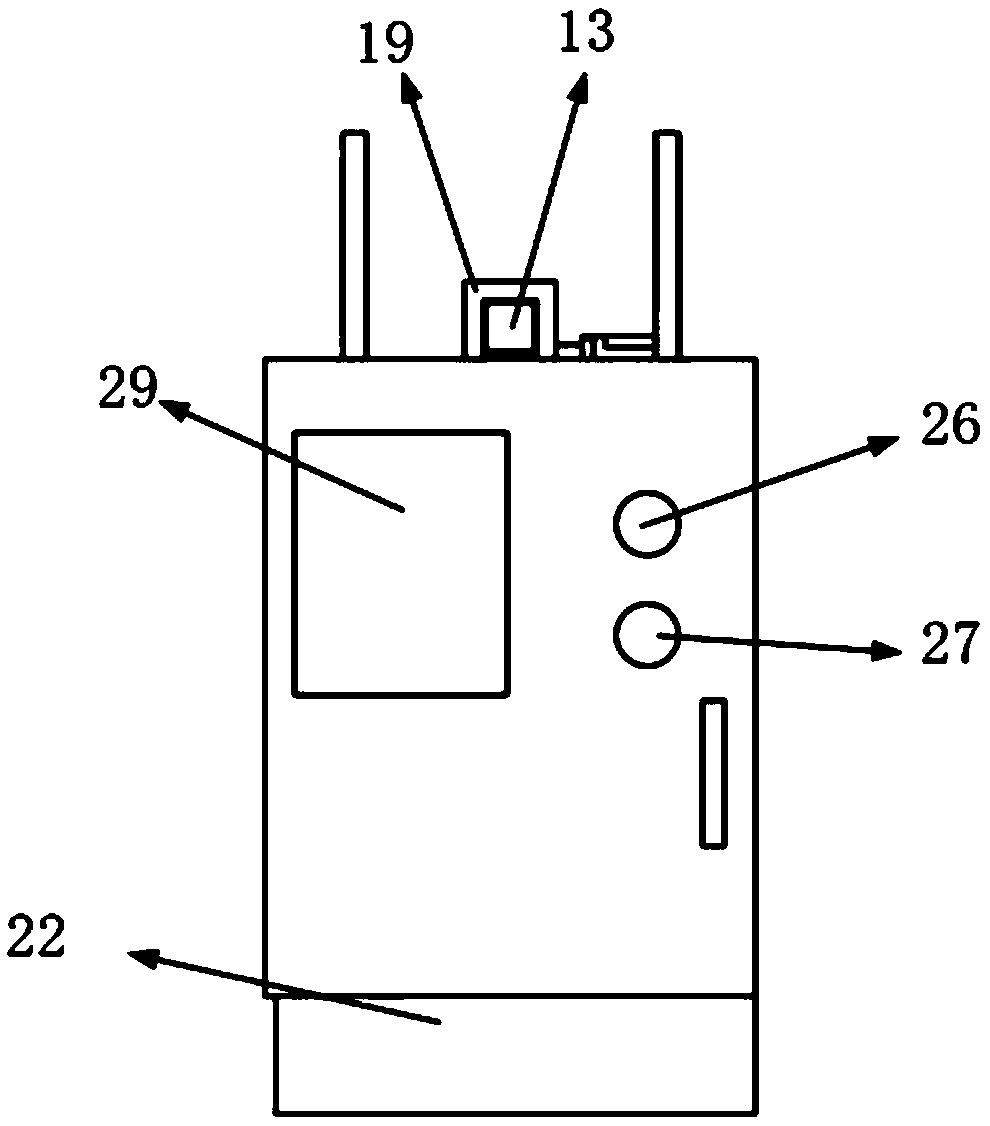

[0028] An intelligent wave-making water tank with active feedback wave-suppression function designed by the present invention is characterized in that the intelligent water tank includes four major areas: active wave-making area a, test area b, wave-suppression area c, and active wave-suppression area d .

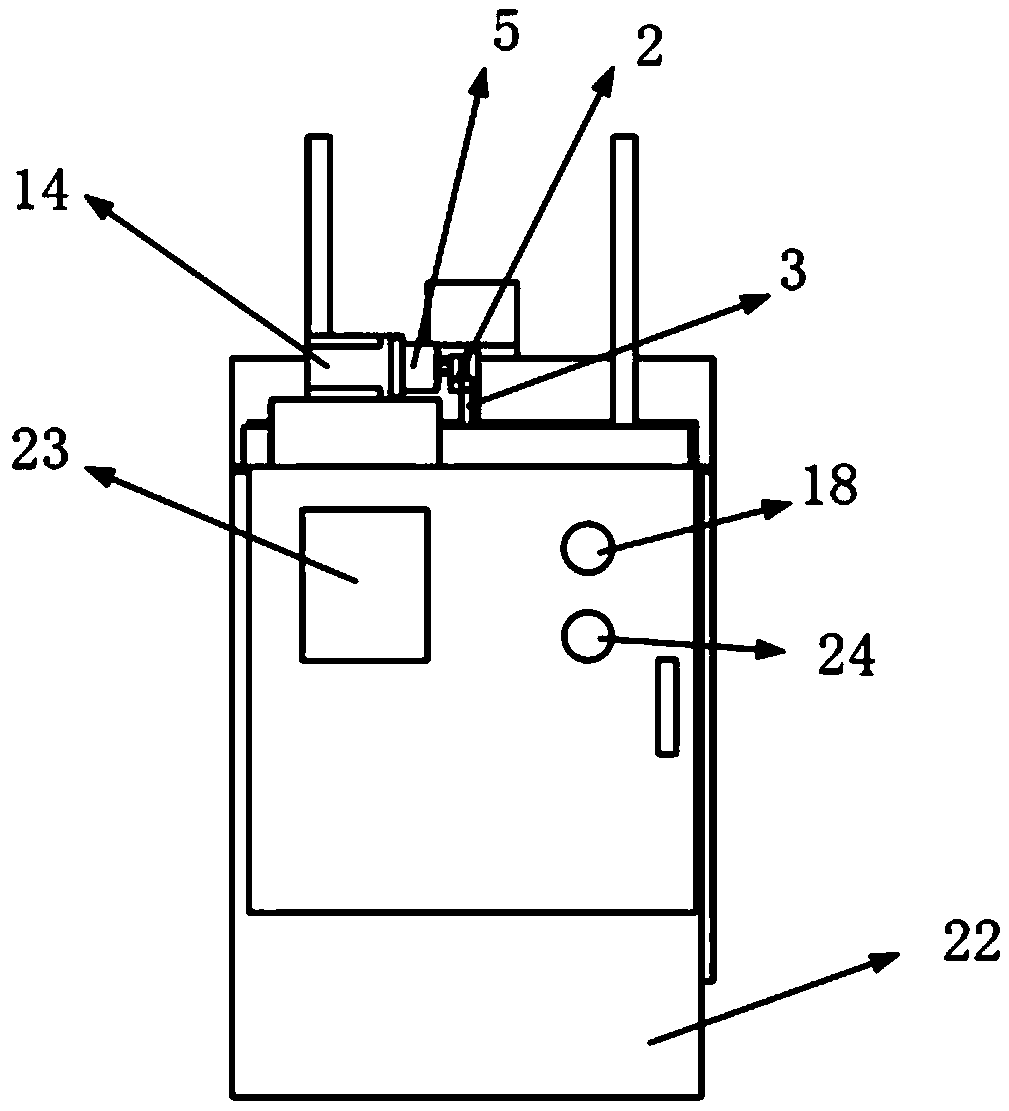

[0029] The active wave-making area a is mainly composed of a wave-making control box 8, a wave-making servo motor 14, a reducer 5, a crank member 2, a hinged rocker 3, a wave-making rocker 6, a wave-making rocker support 11 and a wave-making Zone porous structure 21 composition. The active wave-making system includes a wave-making control box 8, a measurement system computer, a controller, a frequency converter, an encoder, a DC stabilized power supply, and a fan. The measurement system computer, a controller, a frequency converte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com