Belt flattening mechanism

A technology with strips and parallel axes, which is applied in the field of battery cell manufacturing and battery manufacturing equipment. It can solve the problems of reduced deviation correction accuracy and inability to completely eliminate the wave at the edge of the pole piece, so as to improve accuracy, eliminate waves, and eliminate the edge of the pole piece. The effect of accurate position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

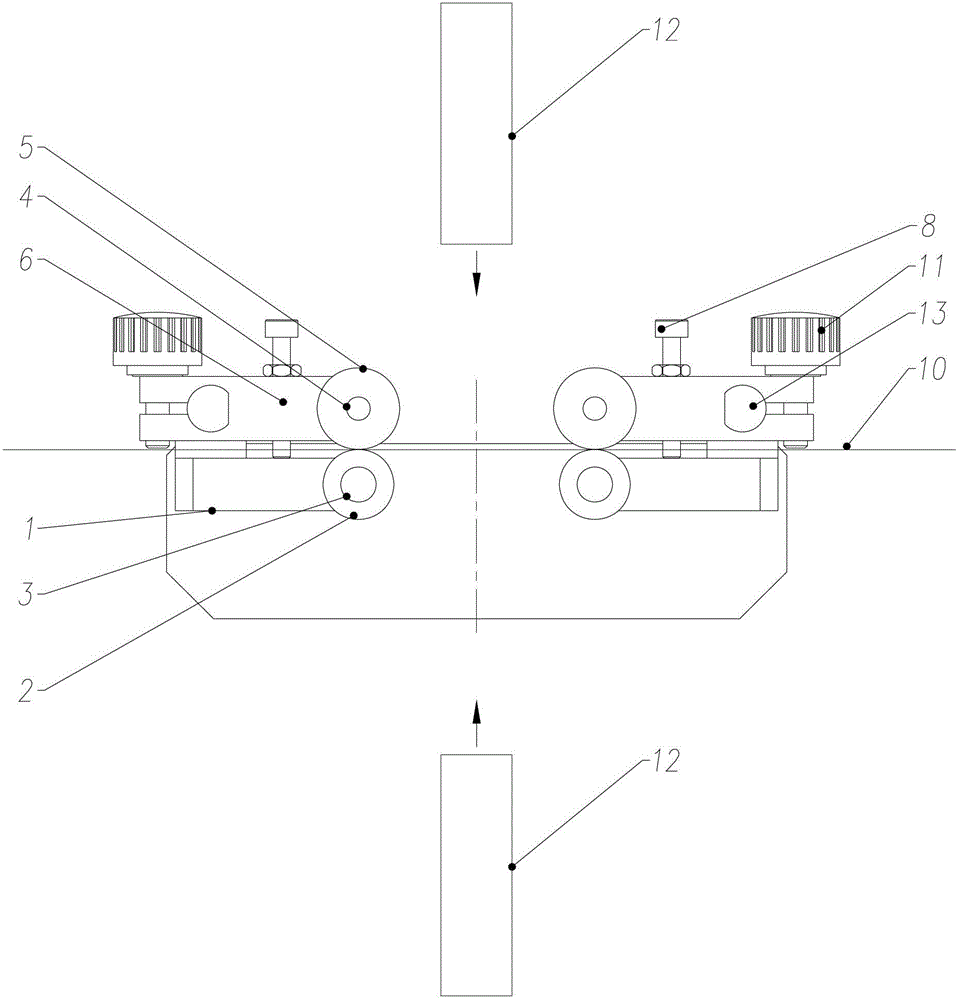

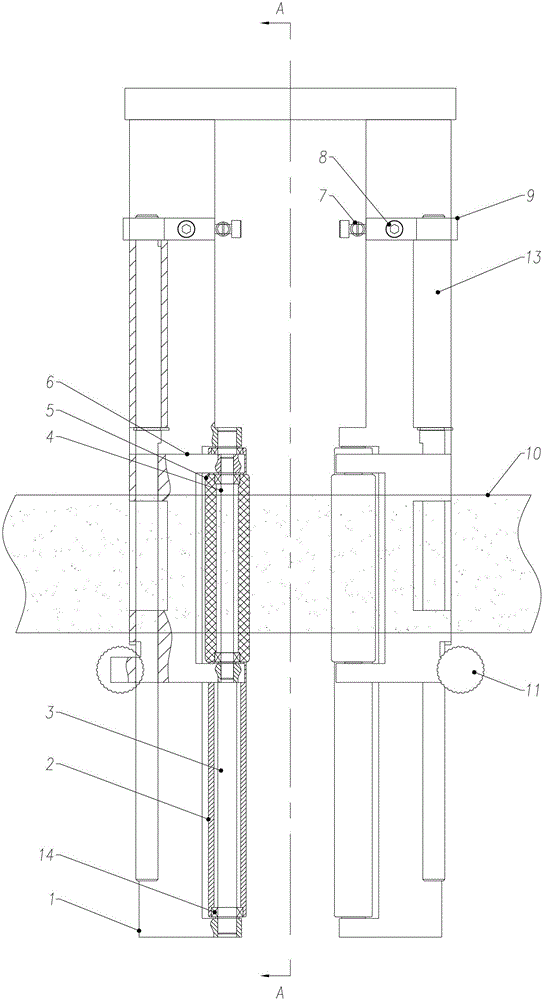

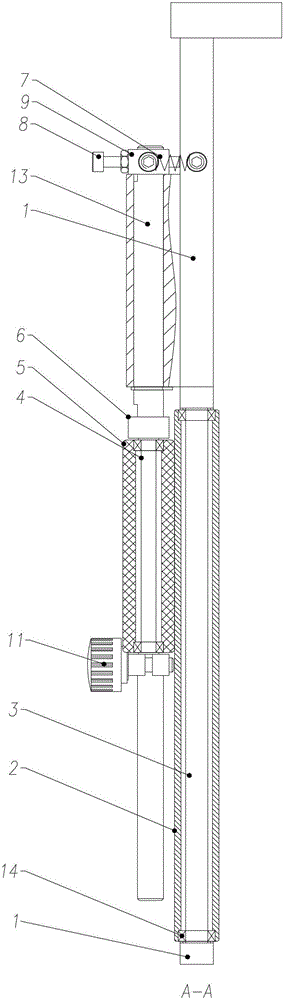

[0016] figure 1 It is the front view of the flattening mechanism embodiment of the strip of the present invention, figure 2 is a top view of the embodiment, image 3 is the left side view of the embodiment.

[0017] The embodiment of the flattening mechanism of the material belt of the present invention is provided with two sets of mechanisms correspondingly, and each set of mechanisms can be divided into a rolling part and a loading part. This structure can realize the function of flattening the strip of the pole piece, and improve the accuracy of the origin position of the deviation correction detected by the through-beam sensor, thereby improving the winding accuracy.

[0018] As shown in the figure, the rolling part is provided with a lower pressing rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com