Marine promoted by front water

A technology of ships and propellers, which is applied in the direction of ship propulsion, propulsion components, hulls, etc., can solve the problems that cannot overcome the publication or launch of ship technology, achieve the effects of timely and flexible navigation trajectory, improve work efficiency, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

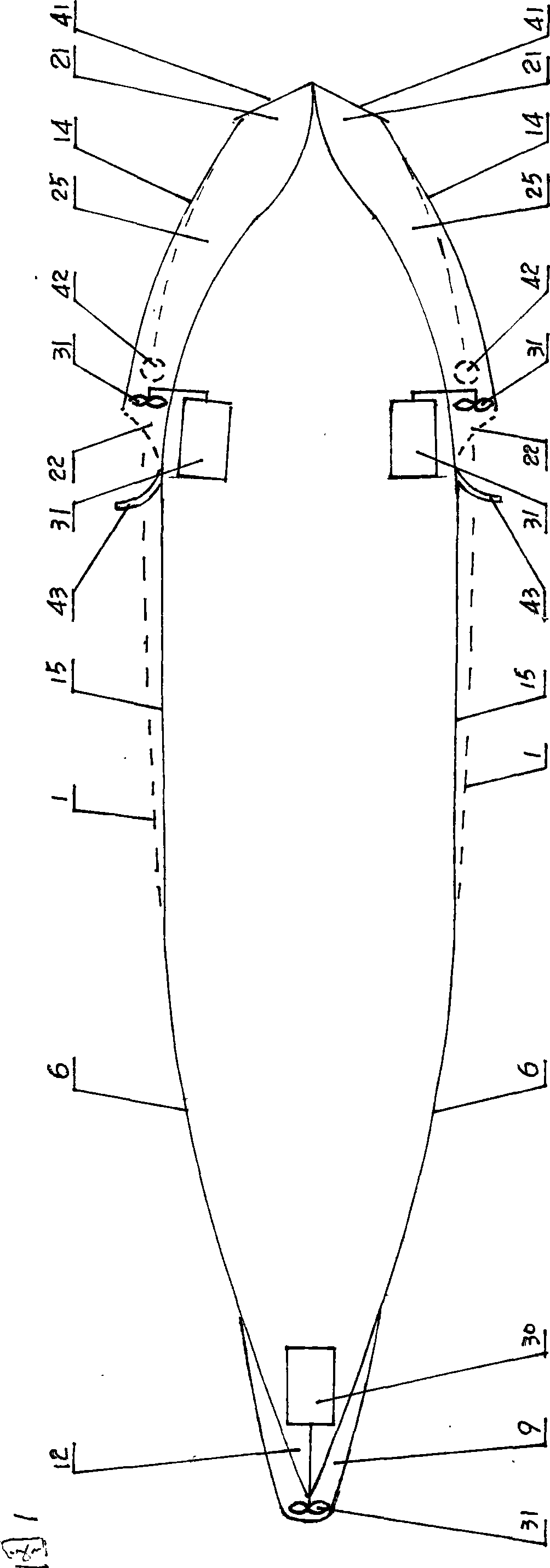

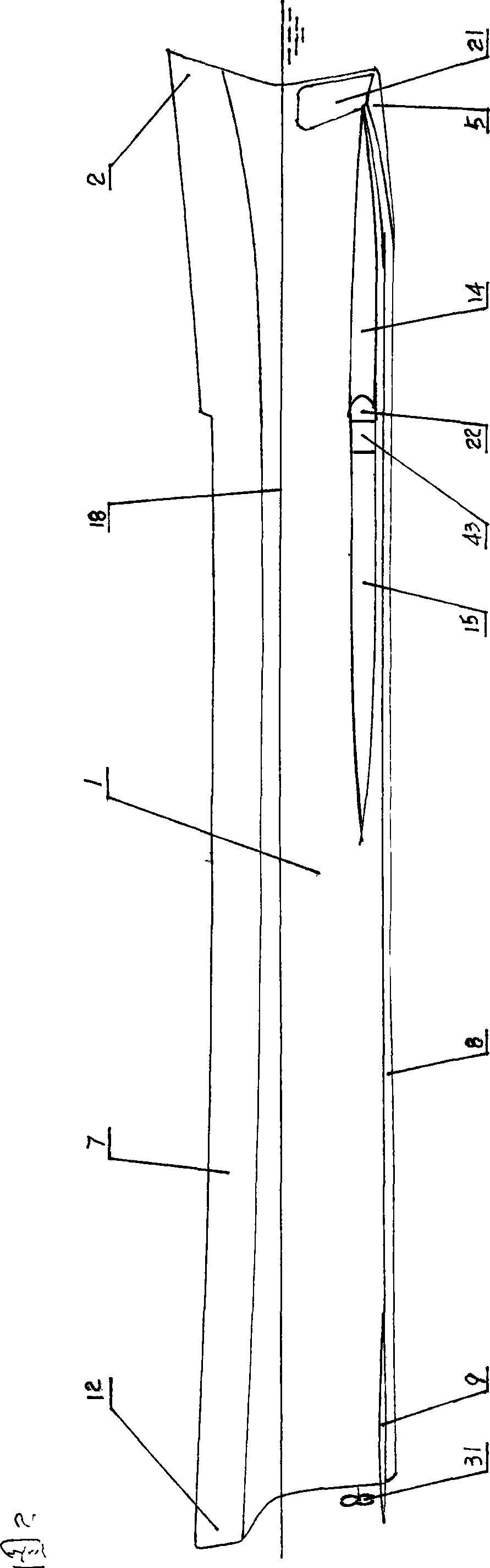

[0069] The propulsion scheme on both sides of the bow of the leading water propelled ship of the present invention will be further described in Embodiment 1 in conjunction with the accompanying drawings.

[0070] As shown in Fig. 1 and Fig. 2, a double-slope plowshare type pipe nose body 5 is set under the water level line in the front projection of the bow 2, and the nose pipes arranged on the slopes on both sides are used as the water inlet 21, and the bottom axis It is the extension of the longitudinal axis of the bottom of the ship. The two sides of the bottom are tilted into a double-wing V shape. The two sides and the upper part are connected with the bow 2, and the adjustable horizontal grid type sewage is set outside the water inlet 21 on both sides. Grid 41. On the upper part of the round bilge 8 of the front shoulder 3 on both sides of the hull 1, the water outlets 22 on both sides of the rearward bow of the symmetrical position and the half of the symmetrical mouth ...

Embodiment 2

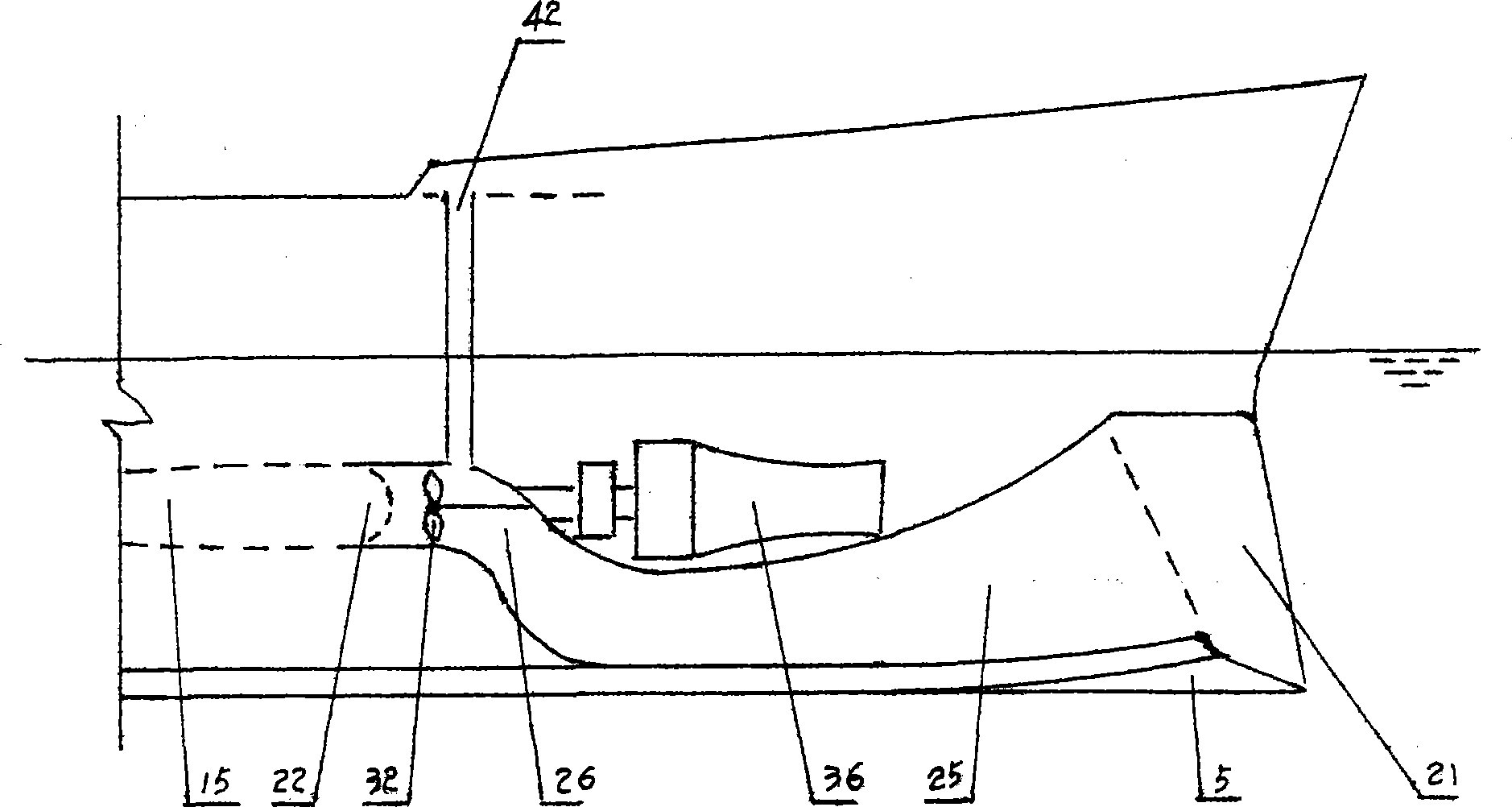

[0079] Below in conjunction with the accompanying drawings, the scheme of setting the stern propulsion and flow layer on the leading water propulsion ship of the present invention will be further described in Embodiment 2.

[0080] As shown in Figures 11 and 12, with reference to Embodiment 1, a pipe nose body 5 is provided in front of the bow and a sewage grid 41 with an extension is provided on the surface of the water inlets on both sides. The lower parts of the rear shoulders 4 on both sides are respectively provided with symmetrical and symmetrical total water outlets 22, and a longitudinal flow layer 23 and branch pipes 24 on both sides are arranged between it and the water inlets 21 on both sides, and the branch pipes 24 on both sides are arranged. Exhaust pipes 42 are arranged on the rear top surface of 24 respectively. Symmetrical or similar counter-rotating spiral diesel propulsion devices 31 are arranged side by side in the main water outlets 22 on both sides. The ...

Embodiment 3

[0084] The combined stern and side propulsion of the leading water propelled ship of the present invention with longitudinal flow tubes and side flow tubes will be further described below in conjunction with the accompanying drawings as Embodiment 3.

[0085] As shown in FIG. 14 , a longitudinally inverted trumpet-shaped flow pipe 24 is arranged on the longitudinal axis of the ship bottom, and a total water outlet 22 and a lower edge extending edge 28 are arranged at the tail of the ship's stern. The same type of parallel counter-rotating twin propellers 31 are arranged in the main water outlet 22, and are driven by the same type of diesel engines 35 respectively arranged on the top thereof. Side flow pipe 25 on both sides among the figure, water outlet 22, protruding body 14, water outlet 15, streamlined flow section 6, propeller propulsion device 31, exhaust pipe 42, side shovel dendrobium 43, blowdown grid 41, diesel engine 35 and The nose body 5 and the water inlet 21 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com