Iron core winding core die for transformer with wound stereoscopic triangular iron core

A transformer core and triangle technology, applied in the field of transformers, can solve the problems of rework, unusable core waviness, complicated core core manufacturing technology, etc., and achieve the effect of improving core quality and tight winding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

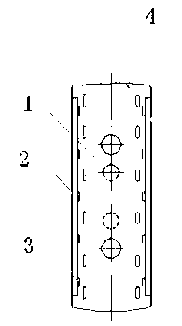

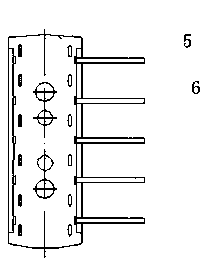

[0013] A three-dimensional triangular wound core transformer core winding mandrel according to the present invention, see figure 1 , the core mold includes a main body 1, on both sides of the main body 1 there are bar-shaped iron blocks 2 that can be separated from the main body 1, and the thickness of the bar-shaped iron blocks can be 15mm. A group of windows 3 are arranged at the joint between the inner side of the bar-shaped iron block 2 and the main body. A group of windows 3 are evenly arranged on the inner side of the bar-shaped iron block, and are used to bind the iron core column 6 through the steel binding band 5 . The upper and lower ends of the main body of the core mold adopt a slightly curved shape 4, so that the silicon steel sheet transitions well at the joints of each side of the core mold when the iron core is wound, and the winding is tight, eliminating the wave of the iron core column during winding, and improving the quality of the iron core. Greatly impro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com