Rebound control method of engine hood outer plate, flanging die and vehicle

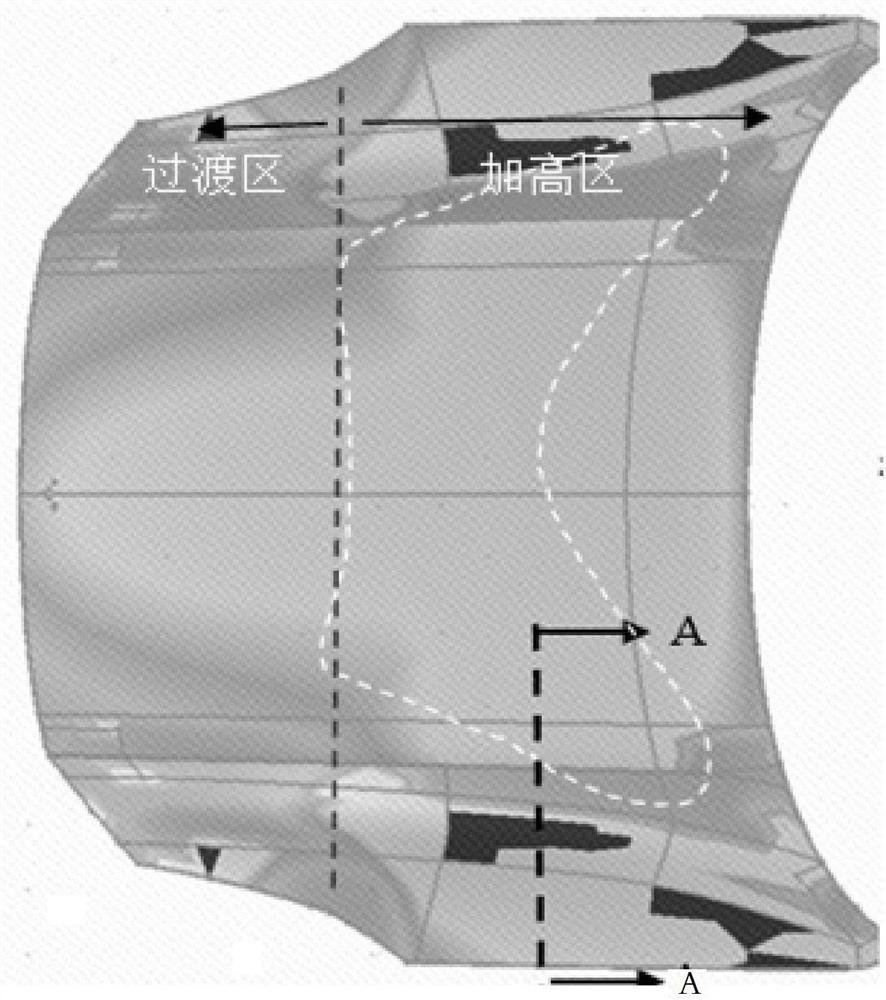

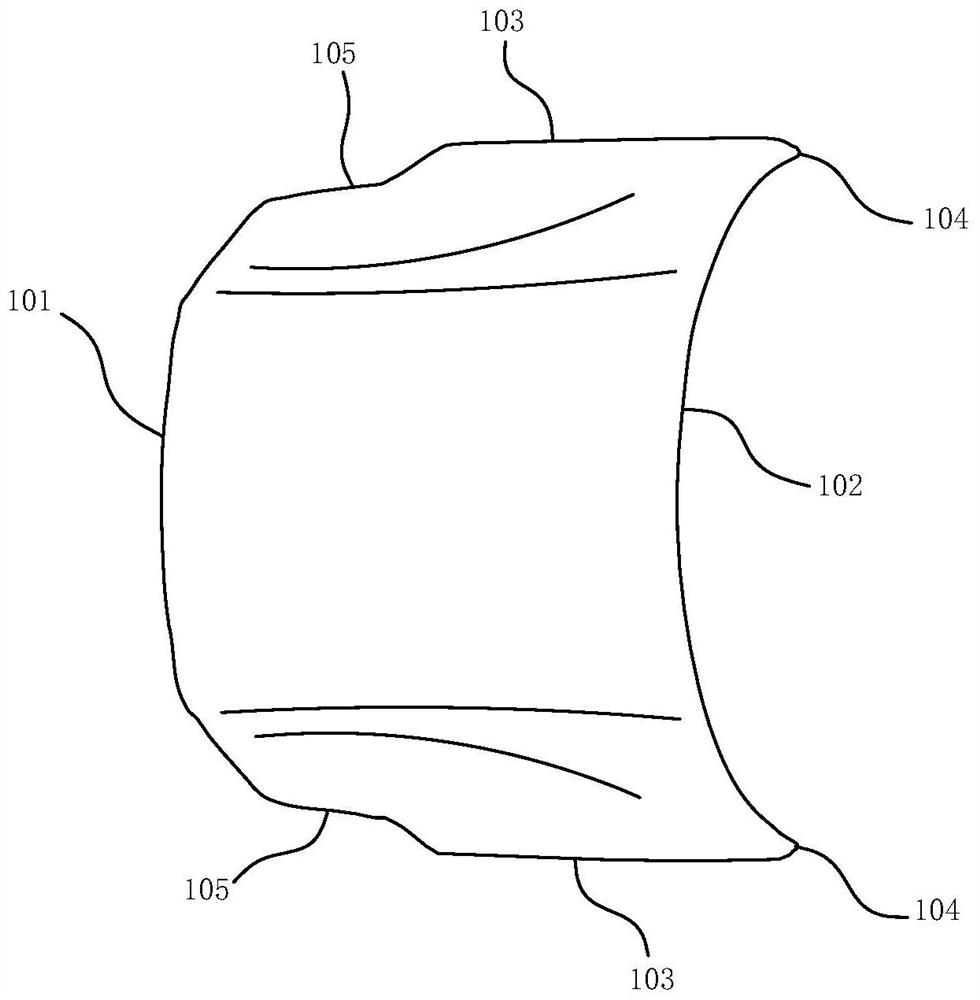

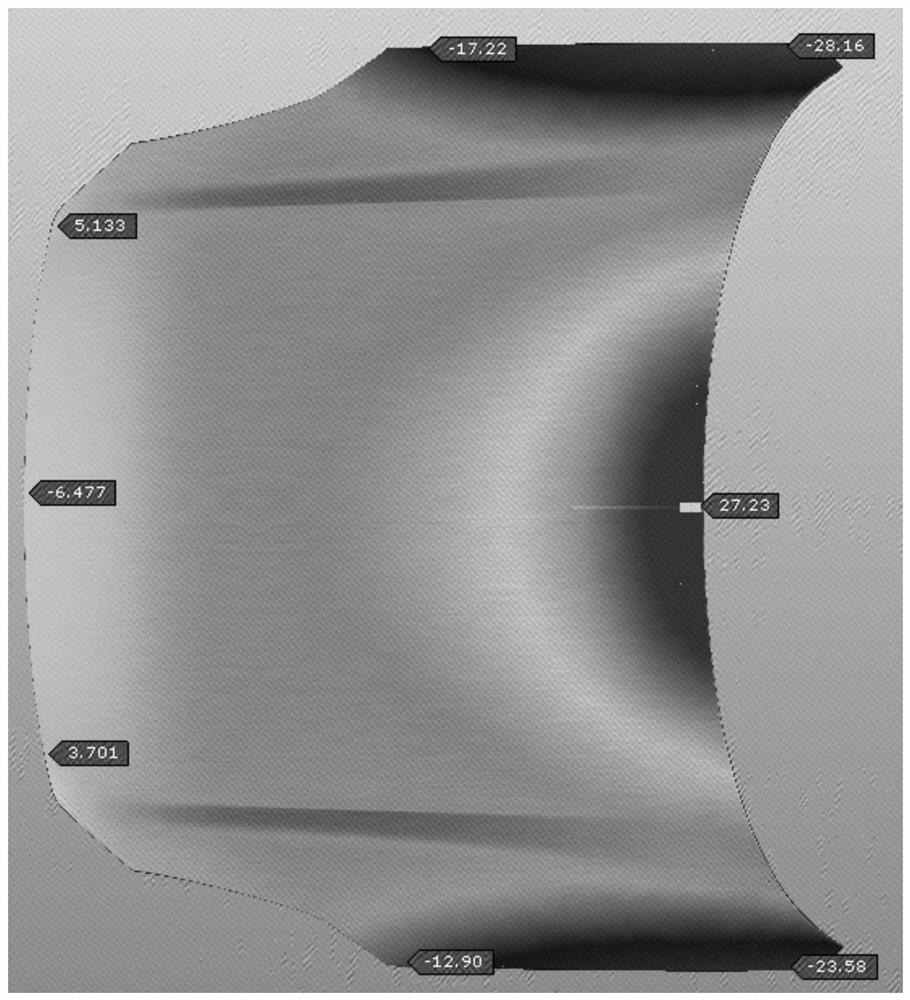

A technology of engine cover and control method, which is applied in the direction of manufacturing tools, vehicle parts, forming tools, etc., and can solve the problem that multiple springback compensation debugging parts cannot meet the acceptance standards, affect the shock-absorbing glue coating of inner and outer panels, and the gap between inner and outer panels is uneven To achieve the effect of improving the appearance quality of the vehicle, eliminating the wave problem, and increasing the height and range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047]The embodiments of the present invention are described below through specific specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification. The present invention can also be implemented or applied through other different specific embodiments, and various details in this specification can also be modified or changed based on different viewpoints and applications without departing from the spirit of the present invention. It should be noted that the following embodiments and features in the embodiments may be combined with each other under the condition of no conflict. It should also be understood that the terms used in the embodiments of the present invention are for describing specific specific embodiments, rather than for limiting the protection scope of the present invention. In the following examples, the test methods without specific conditions are usually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com