Novel withdrawal and straightening machine and working method of withdrawal and straightening machine

A tension leveling machine, a new type of technology, applied in the field of metallurgical equipment, can solve the problems of unsustainable use effect, poor working effect, low production efficiency, etc., achieve improved stretching effect, avoid lace defects, and reduce waste products rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

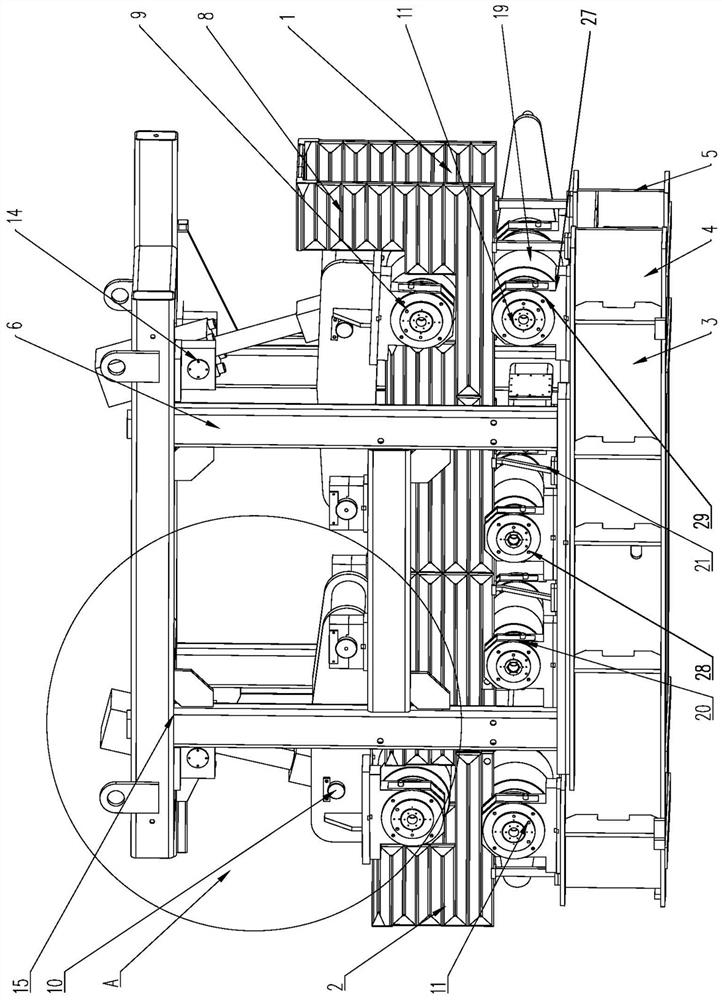

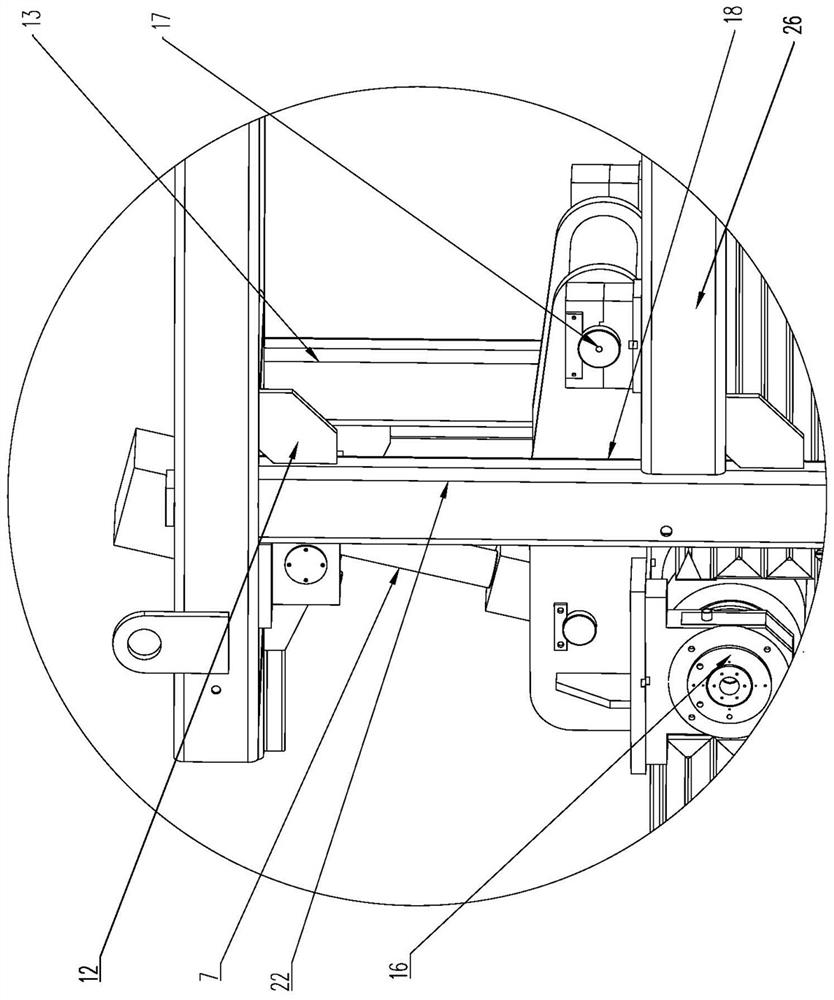

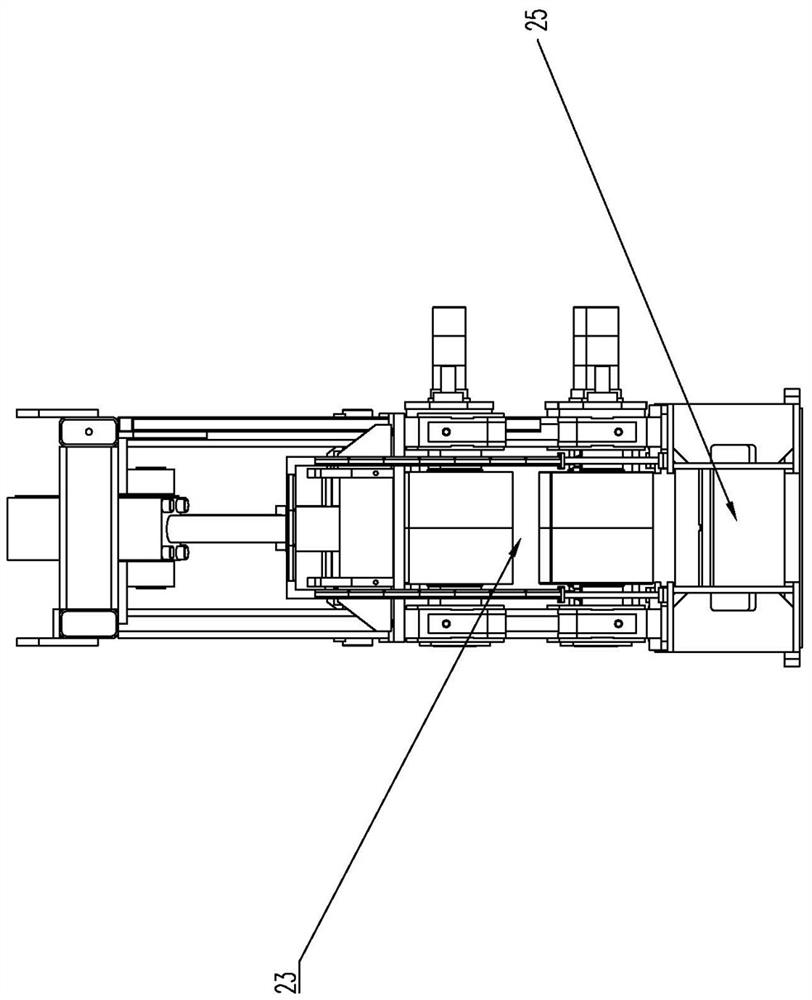

[0030] Such as Figure 1-4 As shown, the purpose of the present invention is achieved in this way: a novel tension straightening machine comprises a base 3 arranged laterally, the base 3 is directly fixed on the ground, and the base 3 is provided with a front feed port 1 and a rear side The discharge port 2; the middle main support frame 6 is installed between the front side feed port 1 and the rear side discharge port 2, and the middle main support frame 6 is arranged along the length direction of the base 3; Reinforcing ribs 12 are also arranged horizontally and vertically respectively, and a baffle assembly 8 is also arranged above the front side feed port 1 to the rear side discharge port 2 on the base 3; the baffle assembly 8 is installed and fixed in the middle On the main support frame 6; the front and rear sides of the middle main support frame 6 are respectively provided with a front side compression adjustment assembly 9 and a rear side compression adjustment assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com