Structured in three layer floorboard from composite solid wood reliev lock caught

The technology of a solid wood composite floor and its production method is applied in the field of three-layer solid wood composite floor and its production equipment, which can solve the problems of small output, unsuitable floor surface relief decoration, and many product restrictions, so as to achieve improved stability, simple laying, Avoid the effect of gap widening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

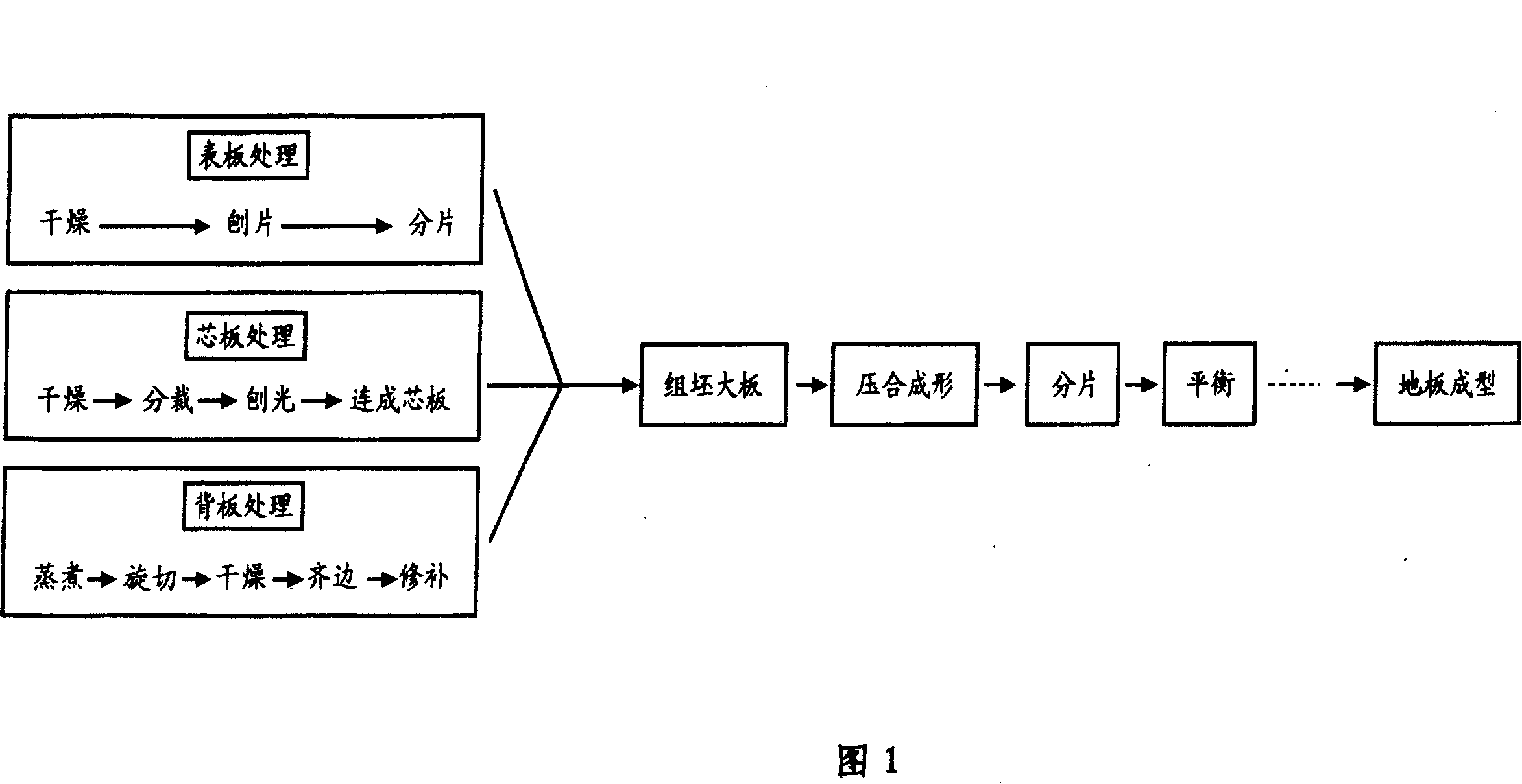

[0034] 1. Three-layer solid wood composite technology, see Figure 1:

[0035](1) Treatment of the surface board: the surface decorative surface is made of high-quality teak wood. After drying, its moisture content is controlled at 10% according to the needs, and then sliced into 3mm solid wood veneer, and then sorted stand-by;

[0036] (2) Treatment of the core board: the core board is made of pine wood, after drying, its moisture content is controlled at 10% as required, and then cut into strips with a thickness of 12mm, a width of 25mm, and a length of 150mm and planed , and then arrange such a group of wooden strips in order along the width direction, and use a saw to cut out a groove with a depth of 3mm at a distance of 4 / 5 from both ends in the length direction, and at the same time fill the groove with a thread that is not easily damaged and glue it with The agent is fixed, so that such a group of wooden strips form a core board with uniform thickness and connected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com