Quick-drying hydroxyacrylic resin aqueous dispersion with long working life and preparation method thereof

A technology of hydroxyacrylic acid and pot life, which is applied in the field of fast-drying hydroxy acrylic resin aqueous dispersion, which can solve the problems of reduced pot life, difficulty in balancing drying speed and pot life, and paint film defects, and achieves long pot life and excellent gloss and fullness, excellent water resistance and solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

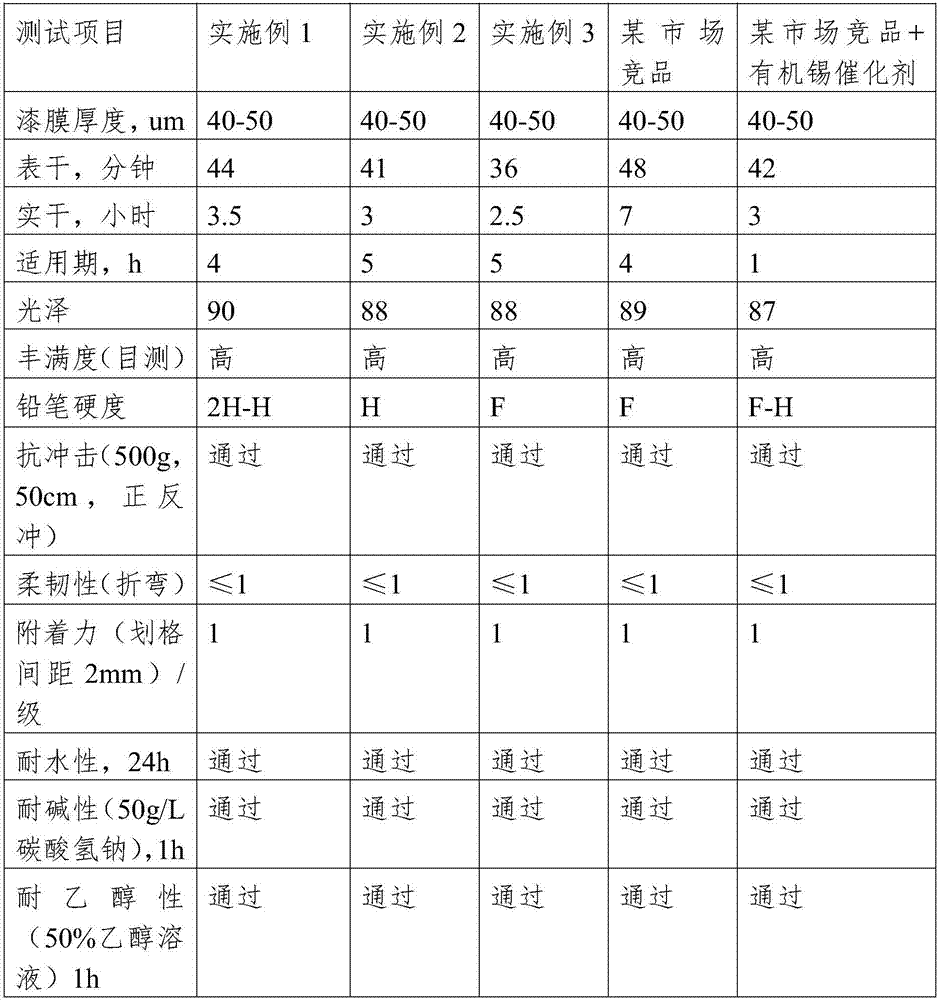

Examples

Embodiment 1

[0038] Example 1 Add 25.0g propylene glycol methyl ether acetate and 30.0g ethylene glycol butyl ether into the reactor, blow nitrogen, stir and heat up to 125°C, start to drop 4.5g ethyl acetoacetate methacrylate, 40.0g formazan A mixture of methyl acrylate, 41.0g styrene, 52.2g hydroxyethyl acrylate, 69.8g n-butyl methacrylate, and 6.2g tert-butyl peroxybenzoate, control the rate of addition uniformly, and drop the mixture in about 3 hours , keep warm for 30min after dripping. After the heat preservation is completed, start to drop a mixture of 33.1g methyl methacrylate, 25.3g hydroxyethyl acrylate, 10.7g butyl acrylate, 10.9g acrylic acid and 3.1g tert-butyl peroxybenzoate, dropwise at a constant speed, within 1h After dripping and keeping warm for 30 minutes, add 1.0 g of tert-butyl peroxybenzoate and keep warm for 3 hours. Cool down to 80°C, add 10.0g dimethylethanolamine and 0.8g dibutyltin dilaurate, stir for 30min, then add 300.0g deionized water at a constant speed w...

Embodiment 2

[0041] Embodiment 2 The mixture of 40g ethylene glycol butyl ether and 30g Solvesso 100 (naphtha solvent) was added in the reactor, nitrogen was blown, the temperature was raised to 150°C with stirring, and 6.2g of acetoacetate ethyl methacrylate was added dropwise, Mixture of 60.0g methyl methacrylate, 31.5g methyl styrene, 42.8g hydroxyethyl methacrylate, 50.3g n-butyl acrylate and 9.1g di-tert-butyl peroxide, control the dropping rate uniformly, about 2.5h After the mixture was dripped, it was kept warm for 30 minutes. After the insulation is completed, start to drop the mixture of 41.1g methyl methacrylate, 22.8g hydroxyethyl methacrylate, 8.9g butyl acrylate, 10.9g methacrylic acid and 4g di-tert-butyl peroxide, dropwise at a constant speed, Add 0.8g of di-tert-butyl peroxide after 30min of heat preservation, continue heat preservation for 3h, lower the temperature to 80°C, add 12.2g of triethylamine and 1.2g of zirconium hydroxide, stir for 30min, and keep the temperatur...

Embodiment 3

[0044] Example 3 A mixture of 40.0g propylene glycol butyl ether and 40.0g glycidyl tertiary carbonic acid ester was added to the reactor, nitrogen was blown, the temperature was raised to 140°C with stirring, and 5.2g ethyl acetoacetate methacrylate, 35.7g formazan A mixture of methyl acrylate, 43.2g styrene, 43.2g hydroxyethyl methacrylate, 65.9g n-butyl methacrylate, and 3.8g cumene peroxide, control the dropping rate evenly, and finish dropping the mixture in about 4 hours , keep warm for 30min after dripping. After the insulation was completed, 31.6g methyl methacrylate, 20.2g hydroxyethyl methacrylate, 10.6g butyl acrylate, 8.2g 2-acrylamido-2-methylpropanesulfonic acid, 20g isopropanol, Add a mixture of 2.1g cumene peroxide dropwise at a constant speed, and finish dropping within 1h30min. After keeping warm for 30min, add 0.7g cumene peroxide, continue keeping warm for 3h, cool down to 80°C, and add 11.6g dimethylethanolamine and 1.0g of bismuth hydroxide, after stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com