Hydrazide latency improving curing agent and preparation method thereof

A technology of latent curing agent and hydrazide compound, which is applied in coatings, epoxy resin coatings, etc., can solve problems such as poor compatibility of epoxy resins, low curing temperature, and brittle coating films, and achieve good compatibility , Moderate curing temperature and long pot life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

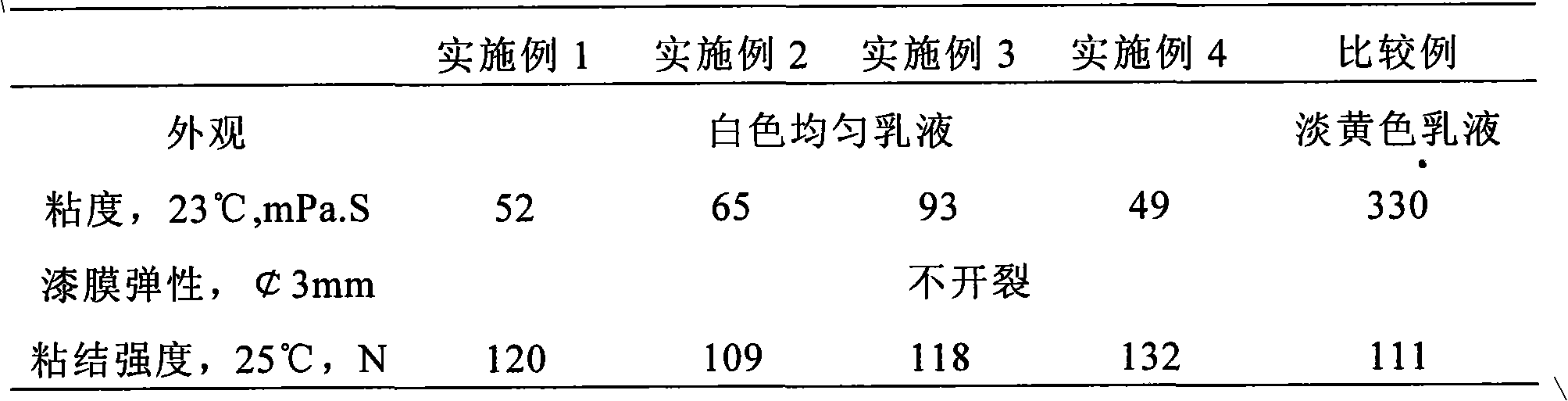

Examples

Embodiment 1

[0046] In a 500ml three-neck flask equipped with an electric stirrer, a spherical condenser and a thermometer, add 250g of isophthalic acid hydrazide, 0.15g of 2-methylimidazole and 150ml of ethylene glycol butyl ether, and heat to dissolve at 120°C , add 150g of butyl glycidyl ether in batches, and then continuously stir and react at this temperature for 8-10 hours, vacuumize to remove the solvent, and the obtained colorless or light yellow sticky substance is the latent curing agent.

[0047] Add 10 grams of alkoxyphenol polyoxyethylene ether surfactant (NP-40), and use the phase inversion method to prepare a latent curing agent emulsion with a solid content of 50% (w / w).

[0048] Get commodity model and be that 100 grams of epoxy resin emulsions of IE-7008W (UPPC company product) and this curing agent emulsion 95 grams evenly mix, add 1.5 grams of leveling agent BYK381 (Munzing company of Germany), 1.3 grams of defoamer EGTAN760 (Germany The one-component water-based epoxy ...

Embodiment 2

[0050] In a 500ml there-necked flask equipped with an electric stirrer, a spherical condenser and a thermometer, add 230g of sebacic acid hydrazide, 0.2g of 2,4,6-tris(dimethylaminomethyl)phenol and 100ml of diacetone alcohol , after heating and dissolving at 120°C, add 180g of phenylglycidyl ether in batches, then continuously stir and react at this temperature for 8-10 hours, vacuumize to remove the solvent, and the obtained colorless or light yellow sticky substance is latent Sexual curing agent.

[0051] Add 15 grams of alkoxyphenol polyoxyethylene ether surfactant (NP-40), and use the phase inversion method to prepare a latent curing agent emulsion with a solid content of 50% (w / w).

[0052] Get commodity model and be that 100 grams of epoxy resin emulsions of IE-7008W (UPPC company) and this curing agent emulsion 95 grams evenly mix, add 1.5 grams of leveling agent BYK381 (Munzing company of Germany), 1.3 grams of defoamer EGTAN 760 (Germany Munzing Company), dubbed one...

Embodiment 3

[0054] In a 500ml three-necked flask equipped with an electric stirrer, a spherical condenser and a thermometer, add 230g of sebacic acid hydrazide, 0.05g of 2,4,6-tris(dimethylaminomethyl)phenol and 100ml of ethylene glycol Diethyl ether acetate, after heating and dissolving at 120°C, add 100 grams of DER332 epoxy resin (Dow company) and 100 grams of butyl glycidyl ether in batches, then continuously stir and react at this temperature for 8-10 hours, and vacuumize to remove the solvent , the obtained colorless or light yellow viscous substance is the latent curing agent.

[0055] Add 20 grams of alkoxyphenol polyoxyethylene ether surfactant (NP-40), and use the phase inversion method to prepare a latent curing agent emulsion with a solid content of 50% (w / w).

[0056] Get commodity model and be that 100 grams of epoxy resin emulsion 100 grams of IE-7008W (UPPC company) and this curing agent emulsion 130 grams evenly mix, add 1.5 grams of leveling agent BYK348 (Germany Munzing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com