Elastic waterproof polyurea coating as well as preparation method and application method thereof

An elastic and coating technology, applied in the field of elastic waterproof polyurea coating and its preparation, can solve the problems of fast curing speed, difficult to repair, short pot life, etc., and achieve the effects of fast curing speed, good adhesion and long pot life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

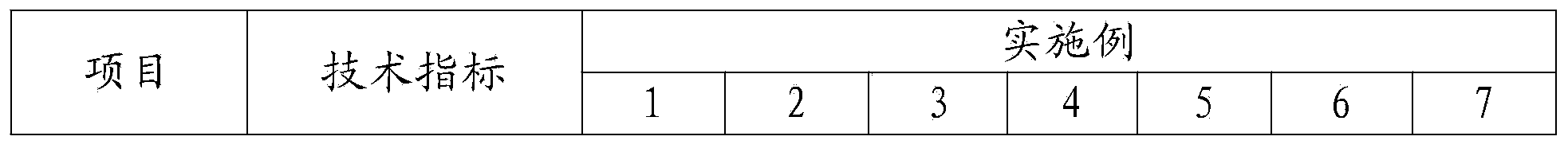

Examples

Embodiment Construction

[0016] In order to fully understand the technical content of the present invention, the technical solution of the present invention will be further introduced and illustrated below in conjunction with specific embodiments.

[0017] The preparation method of elastic waterproof polyurea coating is as follows:

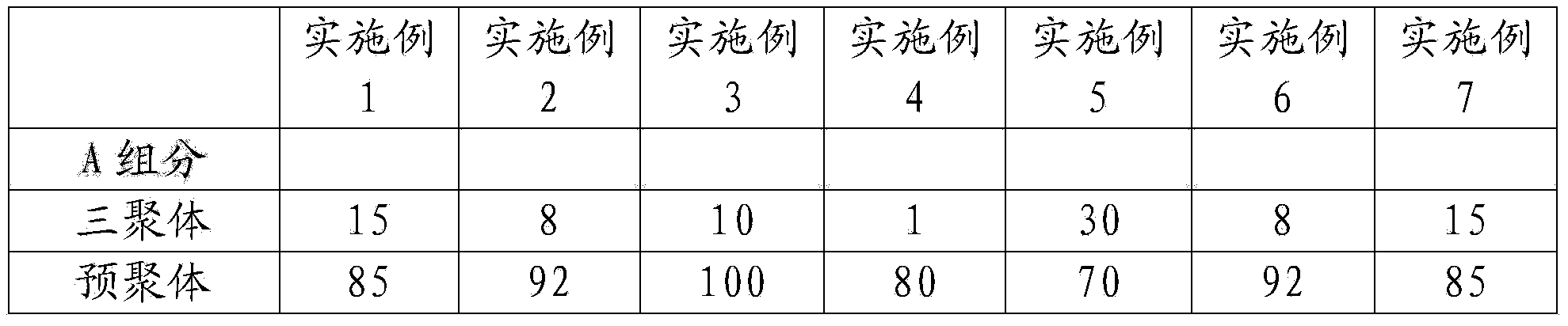

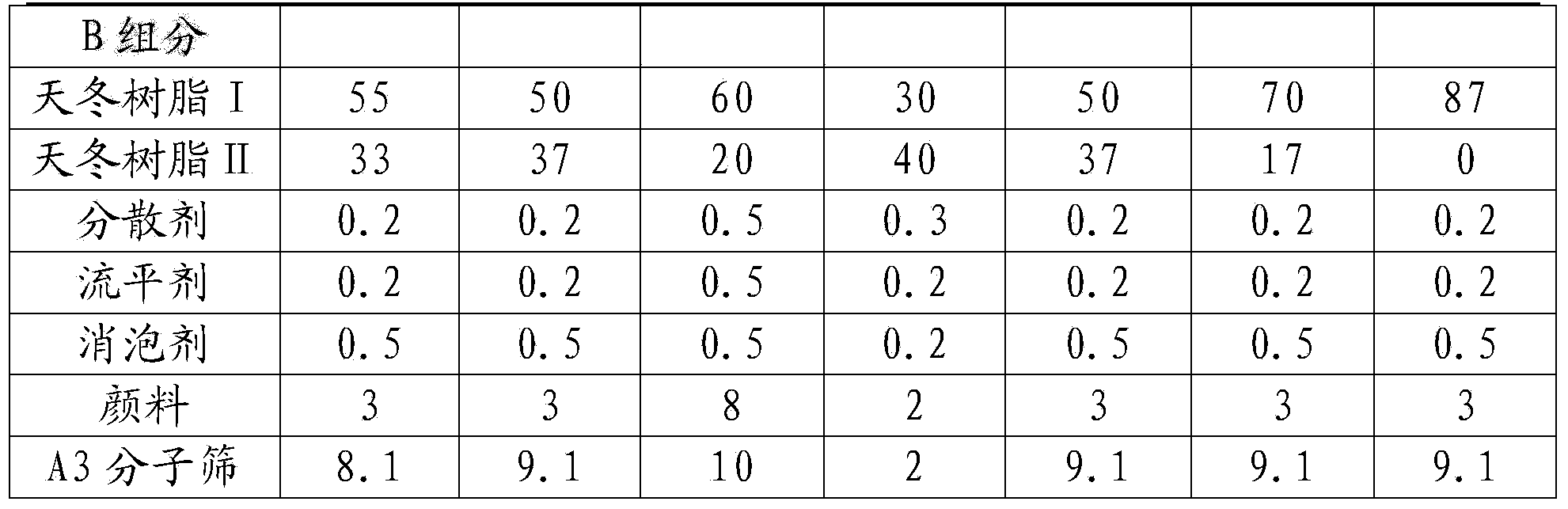

[0018] (1) Add aliphatic polyisocyanate trimer and elastic isocyanate curing agent into the mixing tank, and disperse at a stirring speed of 300-500r / min for more than 20 minutes to obtain component A;

[0019] (2) First add dimeric aspartate polyurea resin into the mixing tank, start stirring at a stirring speed of 300-500r / min, and then add dispersant, leveling agent and defoamer to the mixing tank in sequence , after stirring for 10 minutes, add pigment and dehydrating agent to the mixing tank, and stir for more than 30 minutes until the fineness of the mixture is ≦100 μm to obtain component B;

[0020] (3) Take components A and B of equal mass and package them separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com