Welding control using fuzzy logic analysis of video imaged puddle dimensions

a fuzzy logic and video image technology, applied in adaptive control, process and machine control, instruments, etc., can solve problems such as vexing problems, insufficient reliability, and insufficient accuracy of human knowledge base, and achieve unsatisfactory changes in weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Using Only Width

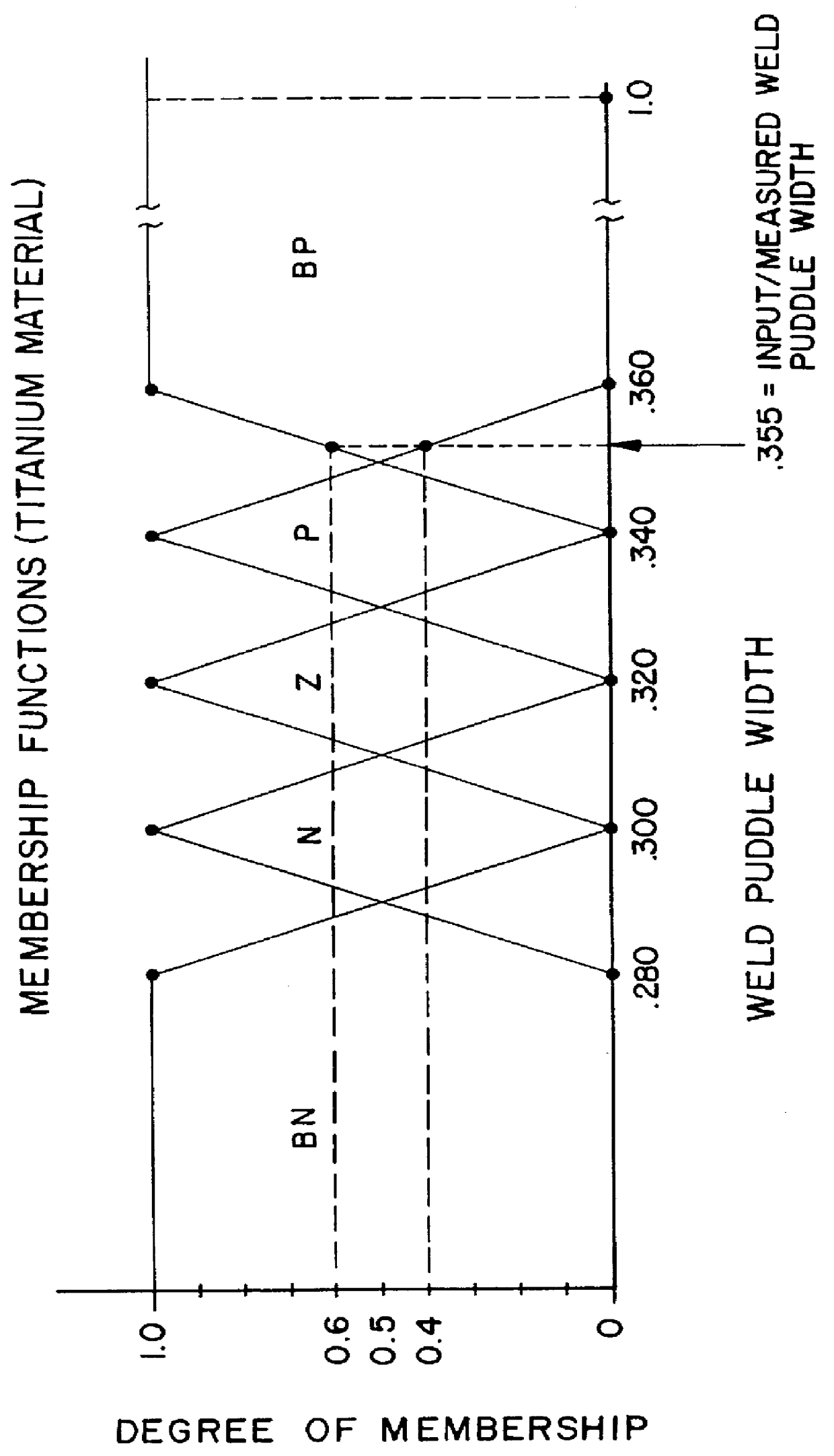

Referring to FIG. 1, if the measured weld puddle width that is measured using the coaxial vision system is 0.355 wide, this measured puddle width value maps to two membership functions: P(positive) .[.an.]. .Iadd.and .Iaddend.BP(big positive). As shown the "P" and "BP" membership functions are defined as follows:

P=0.320 to 0.360

BP=0.340 to 1.00

Two membership functions are operated on in this example: the 0.355 .[.measure.]. .Iadd.measured .Iaddend.puddle width maps to the degree of membership of 0.4 for .[.BP.]. .Iadd.P .Iaddend.and 0.6 for .[.P.]. .Iadd.BP.Iaddend.. The 0.4 and 0.6 indicates the degree of membership for each fuzzy logic membership function that the 0.355 maps into. Therefore, the actual measured width belongs to two membership functions or membership sets.

When two membership functions are involved, the membership function uses an average, weighted by the respective degree of membership values to calculate the crisp or defuzzified output.

Following th...

example 2

Using Length and Width

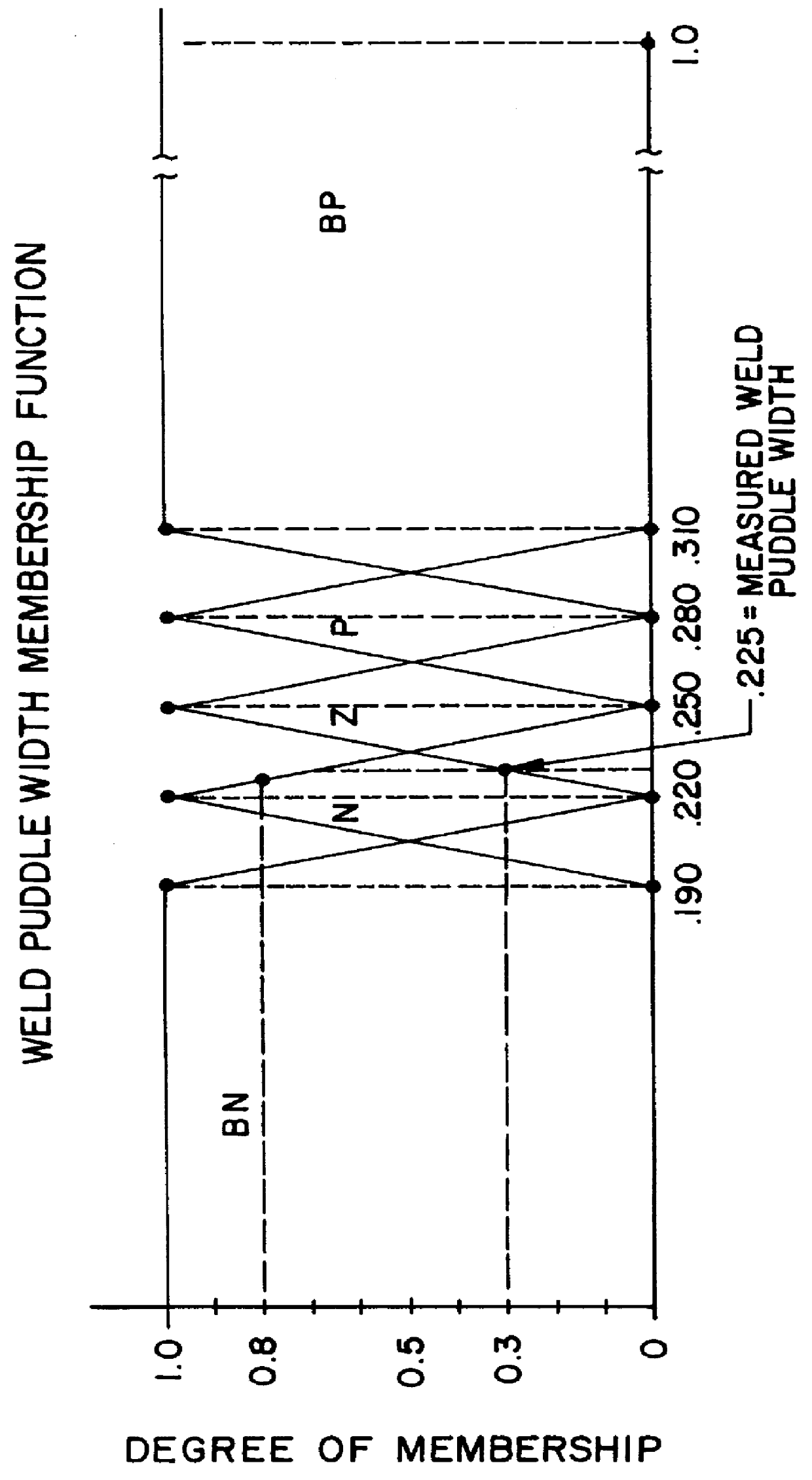

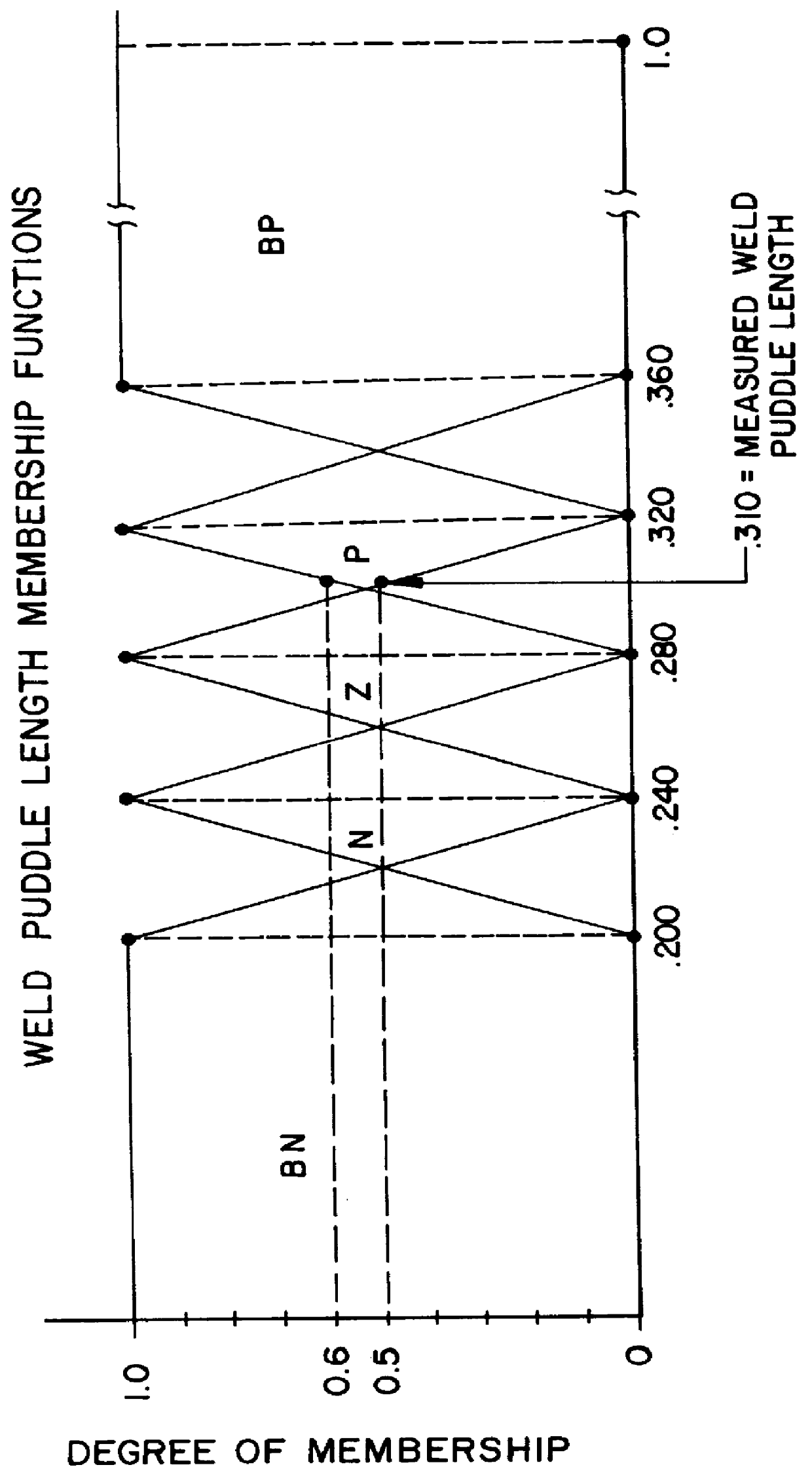

The following example will demonstrate the use of these rules for 17-4 PH stainless .Iadd.steel .Iaddend.or any other material producing a puddle with observable length and width that are indicative of the weld quality in a real time mode.

Assume that the observed weld puddle length=0.310 and the measure weld puddle width=0.225. Using the membership functions in FIGS. 2 and 3, the 0.310 weld puddle length maps as follows: It has two fuzzy logic membership functions. Rule 1) the weld puddle length is in P with a membership of 0.6 and Rule 2) the weld puddle length is also in Z with a membership there of 0.5. For the weld puddle width of 0.225, the width maps to two fuzzy logic membership functions as well: Rule 3) in the function for Z, with a degree of membership there of 0.3 and Rule 4) in the function N, with a degree of membership of 0.8. In this case these four (4) out of the above twenty five (25) rules will fire: Rule 8, 9, 13, and 14. The computation for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric current | aaaaa | aaaaa |

| dimension | aaaaa | aaaaa |

| stored area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com