Cladding and corrosion control method for margin plate at bottom of vertical storage tank

A bottom edge, vertical storage tank technology, applied in the field of anti-corrosion, can solve the problems of low design life of service life, affect the quality of coating construction, difficult to meet anti-corrosion requirements, etc., to save construction time, good airtightness and anti-aging performance , The effect of simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

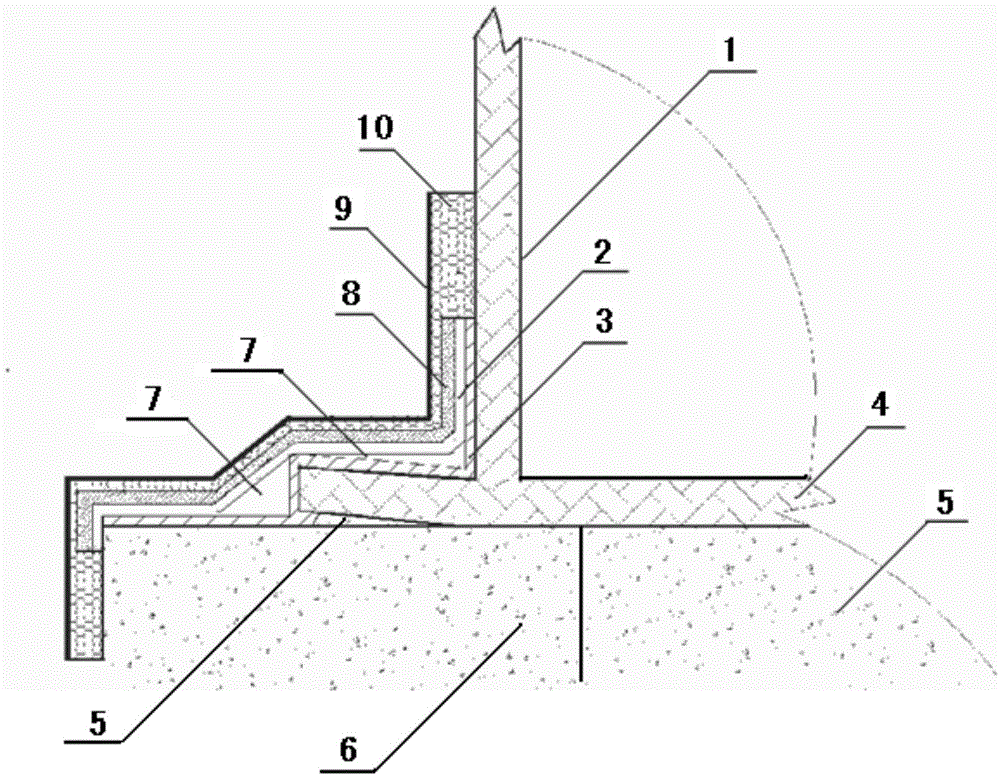

[0040] The present invention will be further described below in conjunction with the accompanying drawings, and embodiments of the present invention will be given.

[0041] The steps of the anticorrosion method for coating the bottom edge plate of the vertical storage tank are as follows:

[0042] 1. Mark the construction area and carry out surface pretreatment

[0043] 1) 200mm above the bottom of the tank, the edge plate of the tank bottom is from the T-shaped joint to its edge, and the width of the asphalt sand protective layer is 100mm, and the 200mm protruding part of the concrete base is the cladding area;

[0044] 2) The surface of the steel base at the bottom of the tank is sandblasted to Sa2.5 level, or polished to St2 level or above for derusting treatment, and the corners of the bottom plate are polished to R angle;

[0045] 3) Repair the concrete base, use epoxy resin paint to seal the surface of the concrete base with a primer, the thickness should not be less th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface dry time | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com