System and method providing arc welding training in a real-time simulated virtual reality environment using real-time weld puddle feedback

A virtual reality and welding system technology, applied in the field of welding simulation, can solve the problem of providing high-level expected feedback for personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

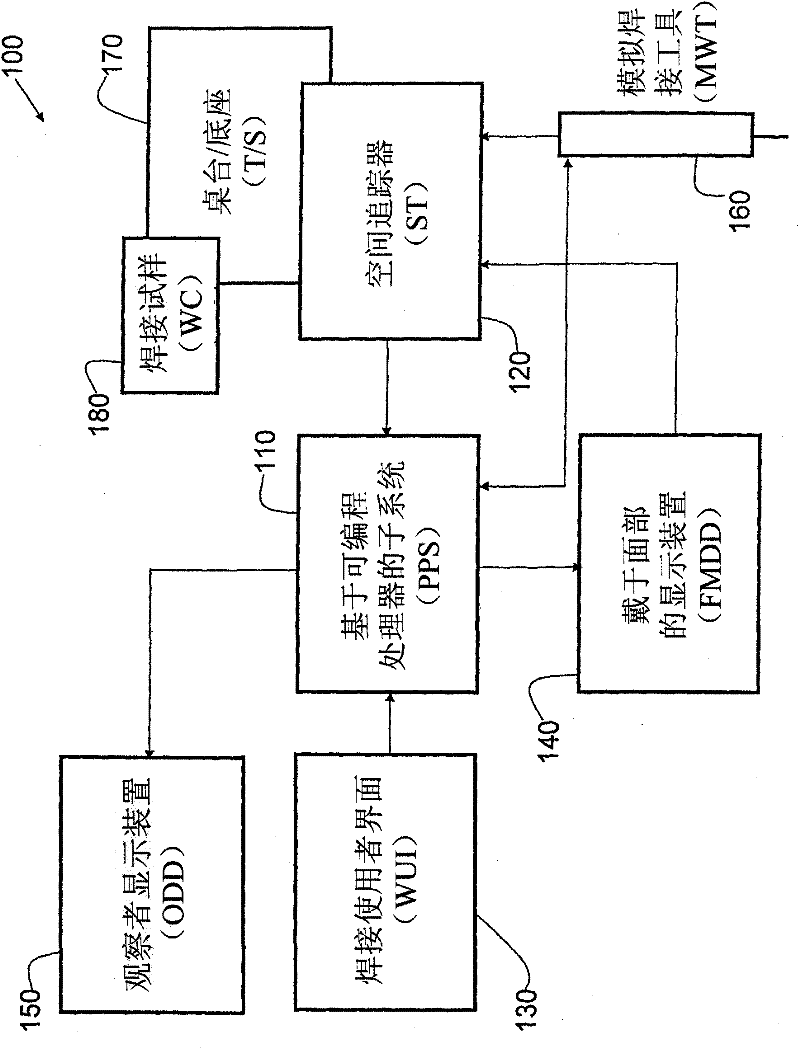

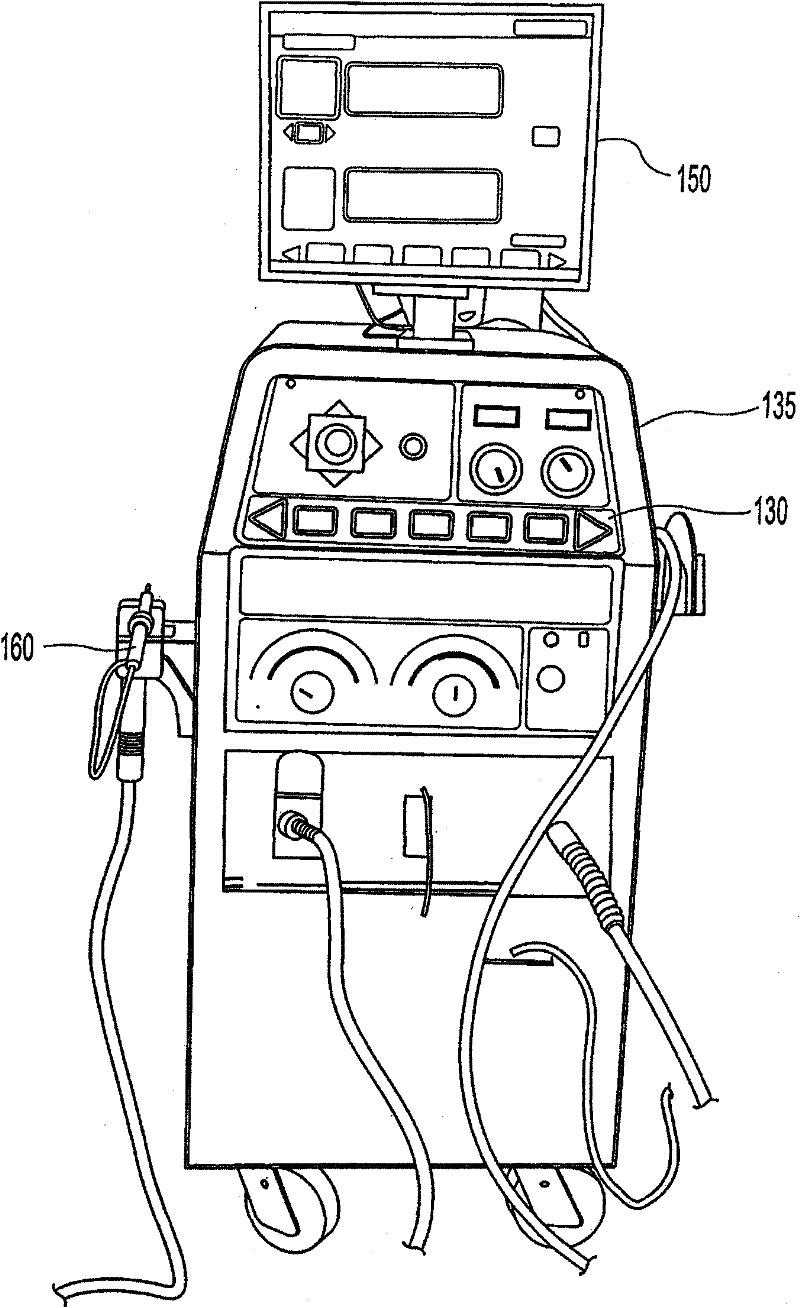

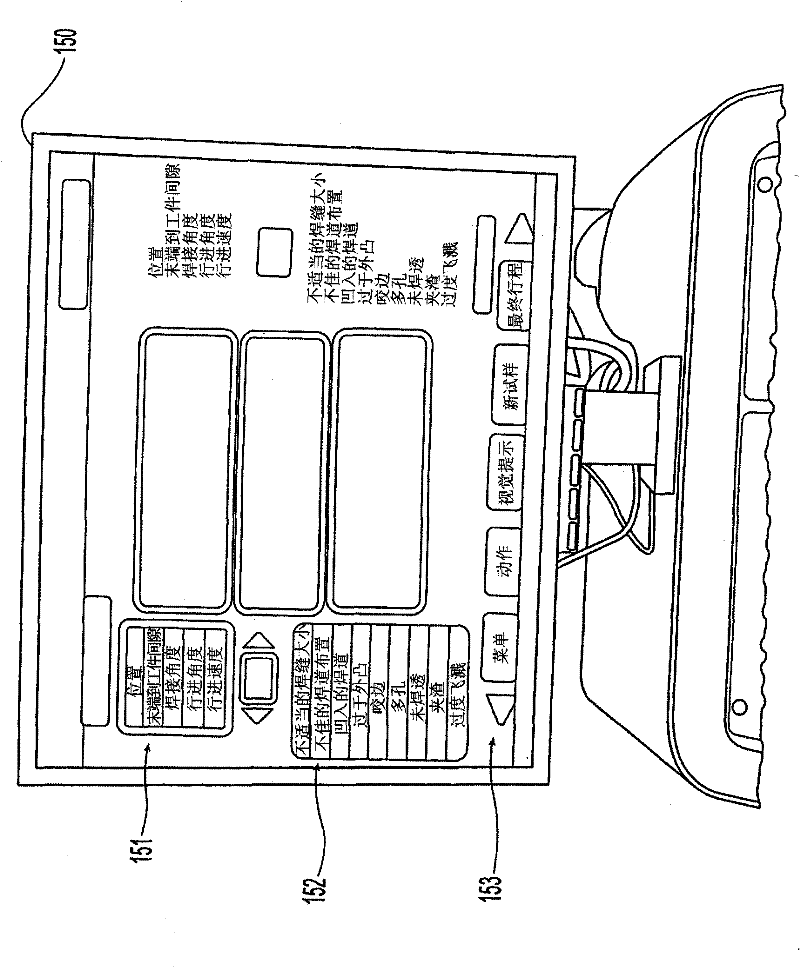

[0030] Embodiments of the present invention include a virtual reality arc welding (VRAW) system comprising a programmable processor-based subsystem, a space tracker, at least one simulated welding tool, and at least one display device, the space A tracker is operatively connected to the programmable processor-based subsystem, the at least one simulated welding tool can be spatially tracked by the spatial tracker, and the at least one display device is operatively connected to the Subsystems based on programmable processors. The system is capable of simulating a molten pool with real-time molten metal fluidity and heat dissipation characteristics in a virtual reality space. The system is also capable of displaying the simulated molten pool on the display device in real time. When displayed, the real-time molten metal flow and heat dissipation characteristics of the simulated weld pool provide real-time visual feedback to the user of the simulated welding tool, allowing the use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com