Plasma-side-suction negative pressure device for laser welding

A laser welding and plasma technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unstable plasma suppression effect, low pumping efficiency of large vacuum chamber, workpiece size limitation, etc. Deep porosity in weld seam, increased stability and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the drawings.

[0021] From a theoretical analysis, laser welding and electron beam welding as a high-energy beam welding method are equivalent in terms of output power density, while electron beam welding has been able to achieve 300mm thick plate welding, so laser welding can achieve the right Welding processing of large thick plates. Since electron beam welding requires a vacuum chamber and the size of the workpiece is limited, more and more attention and attention have been paid to solving the problem of laser welding of large and thick plates, and the present invention came into being.

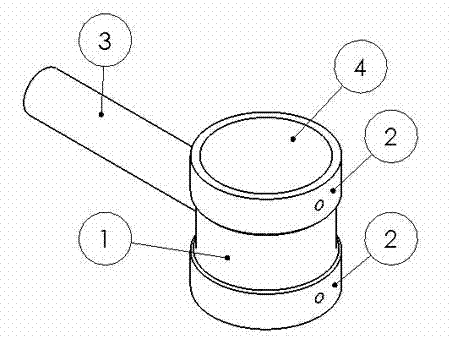

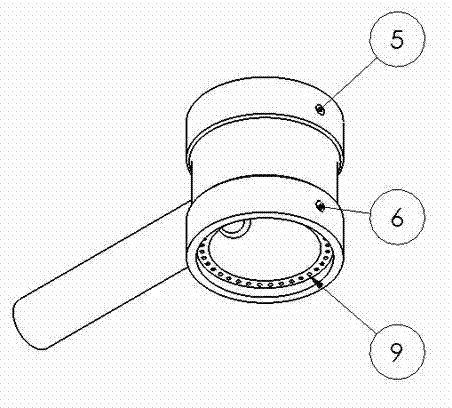

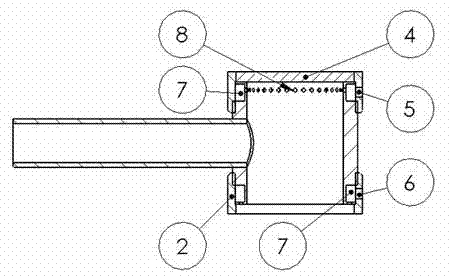

[0022] A laser welding plasma side suction negative pressure device can be installed on any laser welding gun head. The negative pressure cavity device is fixed with the laser welding gun head and can move relative to the workpiece to be welded. The negative pressure chamber device is placed above the weld pool a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com