Dual-component bisphenol A epoxide-resin puddle for construction joint filling and preparation thereof

A kind of epoxy resin mastic, two-component technology, applied in the field of two-component bisphenol A type epoxy resin mastic for building joints, can solve the problems of inconvenient production and construction, cumbersome process, threats to human body and environment, etc., and achieve Long pot life, low viscosity, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

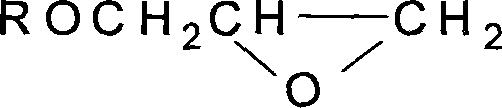

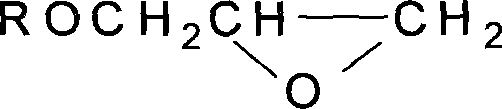

Image

Examples

Embodiment 1

[0035] The preparation method comprises the following steps:

[0036] (1) Preparation of component A: add the bisphenol A type epoxy resin of component A, active dilution toughening agent, talcum powder and fumed silica into the three-roll machine in sequence, and stir for 8-10 minutes to make it Mix evenly to obtain component A;

[0037] (2) Preparation of component B: add active dilution toughening agent, alicyclic amine curing agent, talcum powder and accelerator 2,4,6-tris(dimethylaminomethyl)phenol of component B to another one in turn In the three-roll machine, stir for 8-10 minutes, and mix well to obtain component B;

[0038] (3) Mixing and preparation: mix the component A prepared in step (1) and the component B prepared in step (2) at a ratio of 1:1 by weight, stir for 5 minutes with a three-roller machine or directly mix and prepare by hand. Two-component bisphenol A type epoxy resin mastic for construction joints.

[0039] After mixing, it can be applied ...

Embodiment 2

[0042] The preparation method is the same as in Example 1.

[0043] In this example, component A and component B are mixed at a ratio of 1:0.8. After mixing, it can also be applied within 40 minutes and completely cured within 25 hours. Main performance parameters: viscous strength: 19MPa, viscosity: 9300mPa·S.

Embodiment 3

[0046] The preparation method is the same as in Example 1.

[0047] In this example, component A and component B are mixed at a ratio of 1:1.2. After mixing, it can be applied within 40 minutes and fully cured within 20 hours. Main performance parameters: viscous strength: 18MPa, viscosity: 9000mpa·S.

[0048] From Examples 1, 2, and 3, it is known that when the A component and the B component are between 1:0.8 to 1.2, they can be well mixed and reacted, and the main performance parameters do not change greatly, which provides great benefits for construction. Convenient, can realize the purpose of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com