PCB (Printed Circuit Board) core plate made of Phenolic aldehyde

A PCB board and core board technology, applied in the field of PCB boards, can solve the problems of low peel strength, high brittleness of laminates, and long lamination time, and achieve the effects of improving peel strength, good electrical performance and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described in combination below.

[0009] A core board of a PCB board made of a phenolic material, which includes materials in parts by weight:

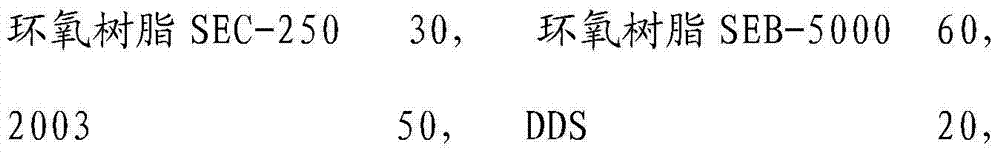

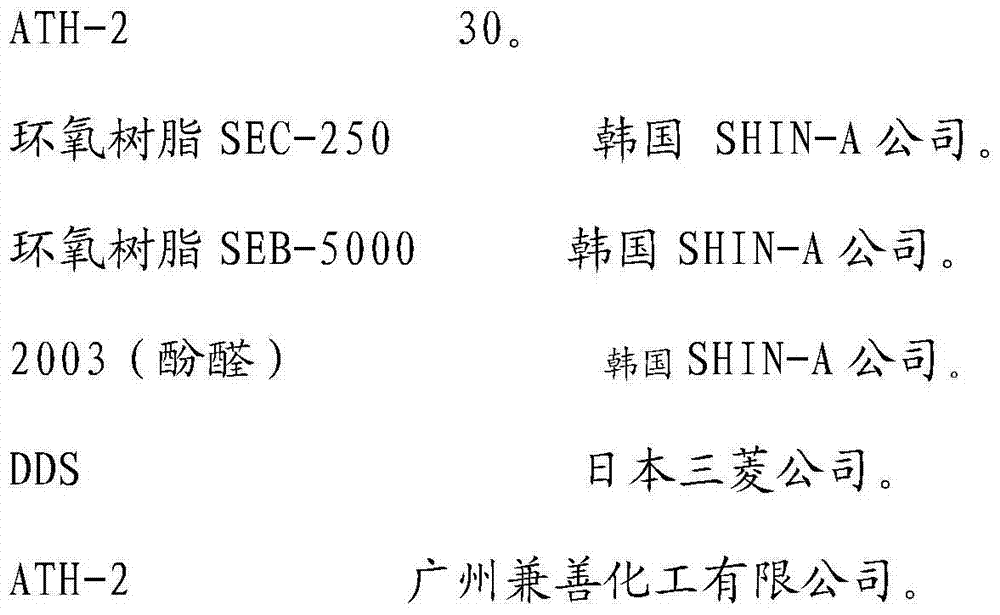

[0010] Epoxy resin SEC-250 30, Epoxy resin SEB-5000 60,

[0011] 2003 50, DDS 20,

[0012] ATH-2 30.

[0013] The preparation method comprises the following steps:

[0014] (1) Glue mixing, (2) Gluing, (3) Lamination.

[0015] Mixing conditions:

[0016] Stirrer 8000 rpm / min / 35℃ / 4h

[0017] Gluing conditions:

[0018] Gluing speed: 15m / min Gluing tension: 12.0N

[0019] Oven temperature: 130°C / 180°C / 220°C

[0020] Lamination conditions:

[0021] Heating rate: 1.5°C / min, vacuum pressure 730Torr, pressure: 2.2MPa

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com