Solid powder combined fuel, and method for preparing the fuel

A technology of solid powder and composition, which is applied in the field of solid powder composition fuel, can solve the problems of large residues, high power consumption of electric heating, and environmental pollution, and achieve the effect of simplified matching technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

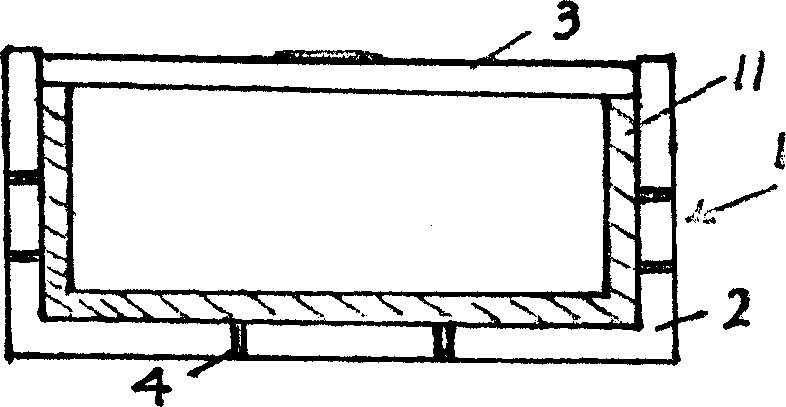

[0016] Example 1: "solid powder composition fuel" is made of mineral flake graphite 100g with a purity of 80%, 35g of magnetic iron ore powder with a purity of 70%, 5g of sea salt, and the particle size is 60 orders. figure 1 In the carrier 1 shown, put the carrier 1 into a microwave oven, start the microwave power of 800W, sinter until all orange light is emitted, take it out and cool it down to room temperature, it is the "solid powder composition fuel" powder absorbing material , is also to ignite the burning fuel with microwaves.

[0017] The above example 1 is put into the loader and ignited and burned with microwaves to make traditional food in a civilian food microwave oven, which can replace fuel oil, coal, and gas stoves to make traditional food, saves electric energy, has fast heating speed, and releases without explosive danger.

example 2

[0018] Example 2 "solid powder composition fuel" consists of 100g of mineral flake graphite with a purity of 90%, 35g of magnetic iron ore powder with a purity of 90%, and 4.5g of sea salt. , The tank wall is made into a sandwich type, and the solid powder composition fuel is filled in the interlayer to a thickness of 10-50 mm, and it is used for heat preservation and heating of the molten iron storage tank during microwave ironmaking.

example 3

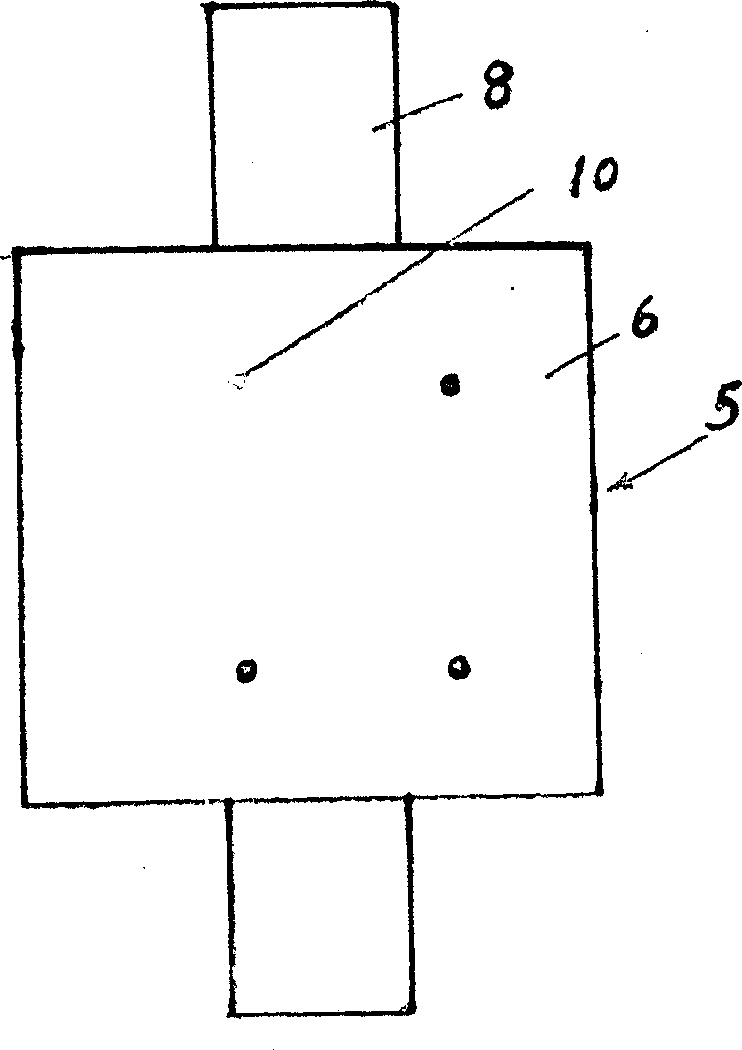

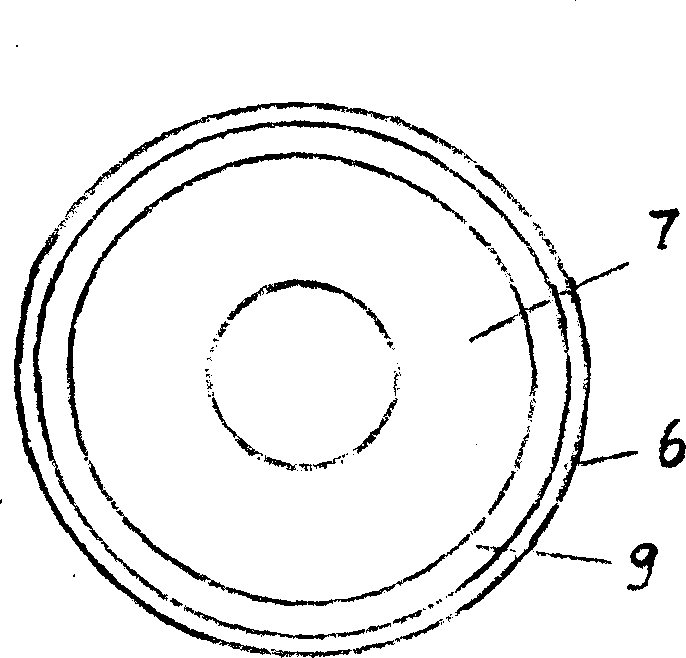

[0019] Example 3 "solid powder composition fuel" consists of 100g of mineral graphite with a purity of 70%, 45g of iron oxide with a purity of 60%, and 6g of table salt. After pulverization, it is fully mixed, put into the interlayer of the wall of the barrel-shaped carrier, put the carrier into the microwave resonant cavity, and adopt the rotation of the carrier or the relative rotation between the carrier and the heated material, which can Evenly heat metal and non-metallic substances. The kiln designed by this method can replace the traditional resistance heating kiln, gas, coal, oil and other kilns. Achieve the goal of sintering ceramics, metallurgical powder devices, and cermet welding with microwaves.

[0020] When the "solid powder composition fuel" is used as a fuel or a wave-absorbing material, it is still placed in a carrier, used as an application device for absorbing microwaves, or ignited and burned by microwaves, and used as a heating substance. The material to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com