Insulating pup joint used for underground mine drilling and manufacture method thereof

A technology of insulating pup joints and manufacturing methods, applied in the direction of drill pipes, drill pipes, drilling equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

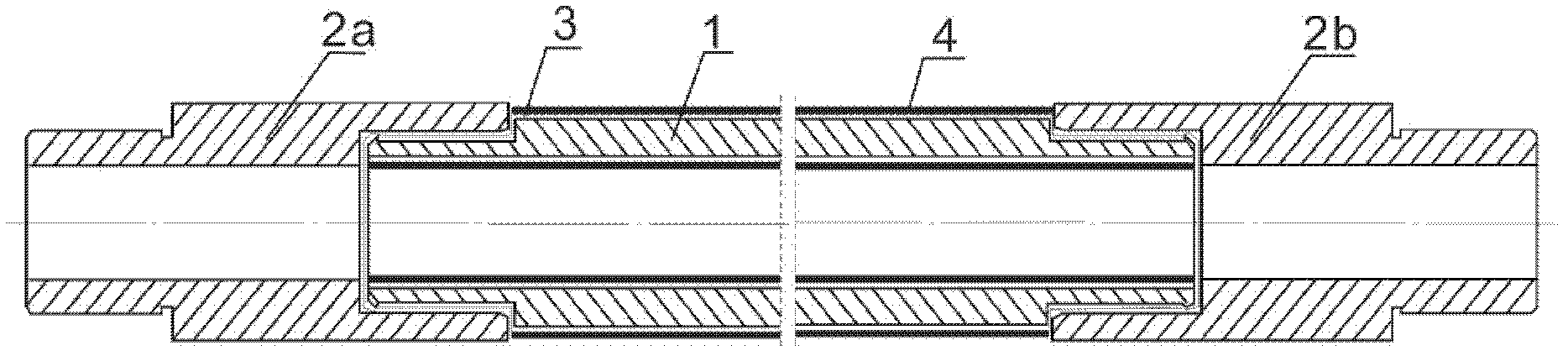

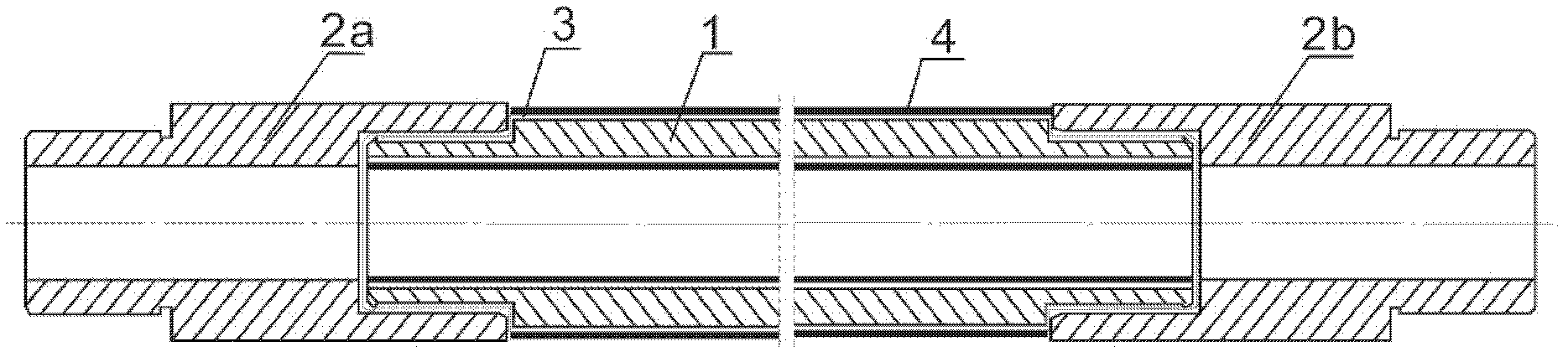

Embodiment 1

[0056] Both the puppet body and the protection joint are made of 40Cr steel. The length of the puppet body is 70cm, the outer diameter is 69mm, and the inner diameter is 40mm. The length of the protection joint is 15cm, the outer diameter is 77mm, and the inner diameter is 35mm. The inner surface, outer surface and end surface of the pup joint body are coated with tungsten carbide ceramic insulating material layer, the Rockwell hardness is 70HRC, and the thickness of spraying is 0.5mm. The inner diameter of the cylindrical plastic template A is 74 mm and the length is 10 cm, and the outer diameter of the cylindrical plastic template B is 35 mm and the length is 10 cm. Use these two templates to pour hard glue and diamond with a thickness of 2 mm on the wear-resistant ceramic insulating material layer on the inner surface of the pup body and on the wear-resistant ceramic insulating material layer on the outer surface of the pup body that is not in contact with the protective joi...

Embodiment 2

[0058] Both the pup joint body and the protection joint are made of 45 steel. The length of the pup joint body is 60cm, the outer diameter is 55mm, and the inner diameter is 41mm. The length of the protection joint is 20cm, the outer diameter is 64mm, and the inner diameter is 36mm. The inner surface, outer surface and end surface of the pup joint body are coated with alumina ceramic insulating material layer, the Rockwell hardness is 75HRC, and the thickness of spraying is 0.8mm. The inner diameter of the cylindrical plastic formwork A is 60mm and the length is 12cm, and the outer diameter of the cylindrical plastic formwork B is 36mm and the length is 12cm. These two templates are used to pour 1.7mm thick hard glue and For the diamond particle mixed material layer 4, the volume ratio of diamond particles and glue is 1:3, the thickness of diamond particles is 100 mesh, the colloid is BD706, and its shear strength is 30 MPa. The two protective joints are fixedly connected wit...

Embodiment 3

[0060] Both the puppet body and the protection joint are made of 45 steel. The length of the puppet body is 70cm, the outer diameter is 84mm, and the inner diameter is 62mm. The length of the protection joint is 25cm, the outer diameter is 92mm, and the inner diameter is 62mm. The inner surface, outer surface and end surface of the pup body are coated with doped ZrO 2 and TiO 2 Al 2 o 3 The ceramic material layer based on the rockwell hardness is 82HRC, and the thickness of spraying is 0.9mm. The inner diameter of the cylindrical plastic formwork A is 89mm and the length is 10cm, and the outer diameter of the cylindrical plastic formwork B is 62mm and the length is 10cm. Use these two templates to pour hard glue with a thickness of 1.6mm and For the diamond particle mixed material layer 4, the volume ratio of diamond particles and glue is 1:2, the thickness of diamond particles is 110 mesh, the colloid is Loctite 4212, and its shear strength is 25-29 MPa. The two protecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com