Improved method and device for high water pressure difference gate sealing

A technology of high water pressure difference and water stop device, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve problems such as water leakage, reduce wear, enhance water stop effect, and reduce friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

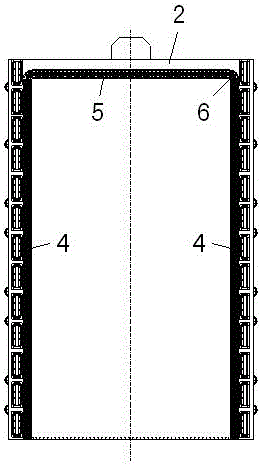

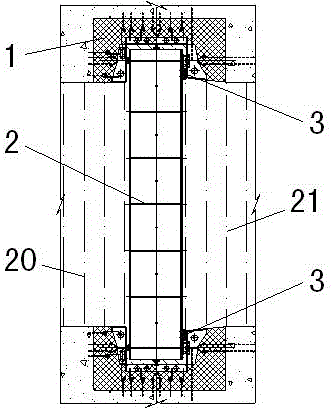

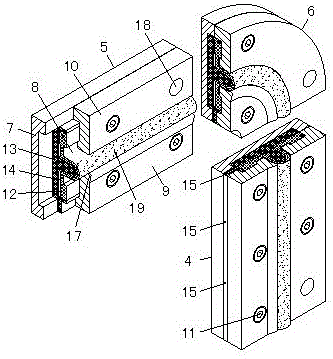

[0025] in the gate slot 1 gate 2 . at the gate 2 The downstream side is symmetrically equipped with a door-shaped water stop device 3 , in the door slot 1 Upper setting and water stop device 3 The position of the water seal head corresponds to the water seal seat plate 16 . Water stop device 3 Asymmetrical concave water seal support seat 7 , water seal 8 , inner pressure plate 9 and outer pressure plate 10 composition. Asymmetric concave water seal support seat 7 Fastened to the gate by welding 2 on, the rest of the components are bolted through the 11 And asymmetrical concave water seal support seat 7 fixed on the gate 2 superior. water seal 8 water inlet hole for the side 15 The round head "mountain" type water seal, its internal setting U Cavity 14 , inlet hole 15 Approximate equidistant setting, water inlet holes 15 and downstream water bodies 21 connected, water inlet 15 and U Cavity 14 Connected; the water seal mate...

Embodiment 2

[0027] in the gate slot 1 gate 2 . at the gate 2 The downstream side is symmetrically equipped with a door-shaped water stop device 3 , in the door slot 1 Upper setting and water stop device 3 The position of the water seal head corresponds to the water seal seat plate 16 . Water stop device 3 Asymmetrical concave water seal support seat 7 , water seal 8 , inner pressure plate 9 and outer pressure plate 10 composition. Asymmetric concave water seal support seat 7 Fastened to the gate by welding 2 on, the rest of the components are bolted through the 11 And asymmetrical concave water seal support seat 7 fixed on the gate 2 superior. water seal 8 water inlet hole for the side 15 The round head "mountain" type water seal, its internal setting U Cavity 14 , inlet hole 15 Approximate equidistant setting, water inlet holes 15 with upstream water body 20 connected, water inlet 15 and U Cavity 14 Connected; the water seal materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com