Polyurethane rubber PTMEG-F composite material and preparation method thereof

A technology of polyurethane rubber and composite material, applied in the field of polyurethane rubber PTMEG-F composite material and its preparation, can solve the problems of high density, large amount of consumables, easy size change, etc., and achieve the effect of low density, material saving and dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

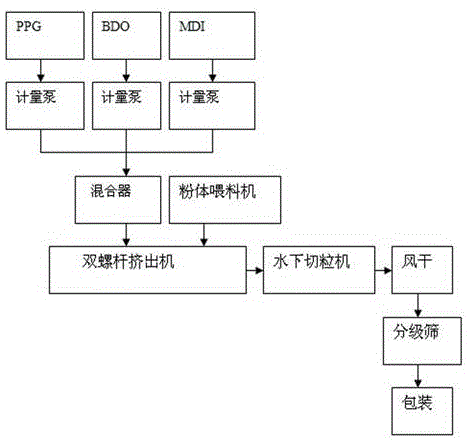

Method used

Image

Examples

Embodiment 1

[0022] A polyurethane rubber PTMEG-F composite material, including polyether polyol (PPG), isocyanate (MDI), crosslinking agent and foaming aids, wherein the foaming aids include catalysts, additives, water, surface active agent, triisocyanate, sulfur accelerator, foaming agent, internal lubricant, external lubricant, colorant.

[0023] The mass percentage of each component of the rubber composite material is: 50%-70% polyether polyol (PPG), 18%-50% isocyanate (MDI), 6%-9% crosslinking agent, 1-3% catalyst , 4-5% additives, 0.9-2% water, 1-10% surfactant, 1-4% triisocyanate, 1-3% sulfur accelerator, 2-4% foaming agent, 1-3% Internal lubricant, 2-3% external lubricant, 1-10% colorant.

[0024] The crosslinking agent adopts 1.4 butanediol or hexylene glycol.

[0025] The linking agent adopts HQEE (4-hydroxyethyloxyethyl-1-hydroxyethylphenylene ether)

[0026] The catalyst adopts metal stannous octoate, dibutyltin dilaurate and mercury acetate.

[0027] The catalyst uses non-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com