Method for manufacturing scraping knife

A manufacturing method and scraper technology, applied in the field of parts and components, can solve the problems of numerous scraper production processes, affecting the quality of scraper powder control, and reducing scraper flatness, etc., so as to reduce the production process, reduce the cost of production raw materials, and reduce the effect of the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0035] Scraper production method steps

[0036] 1) Mold preparation

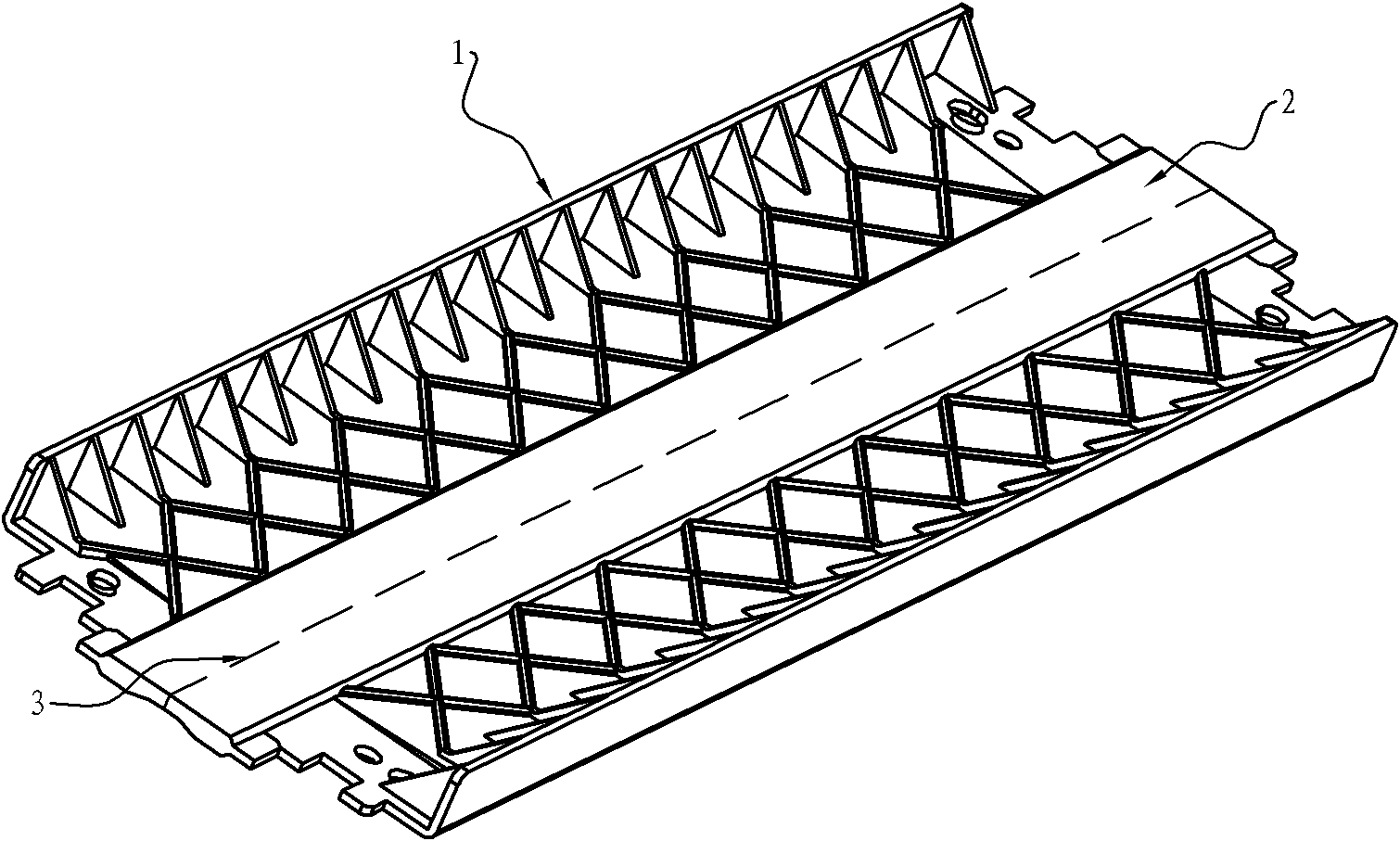

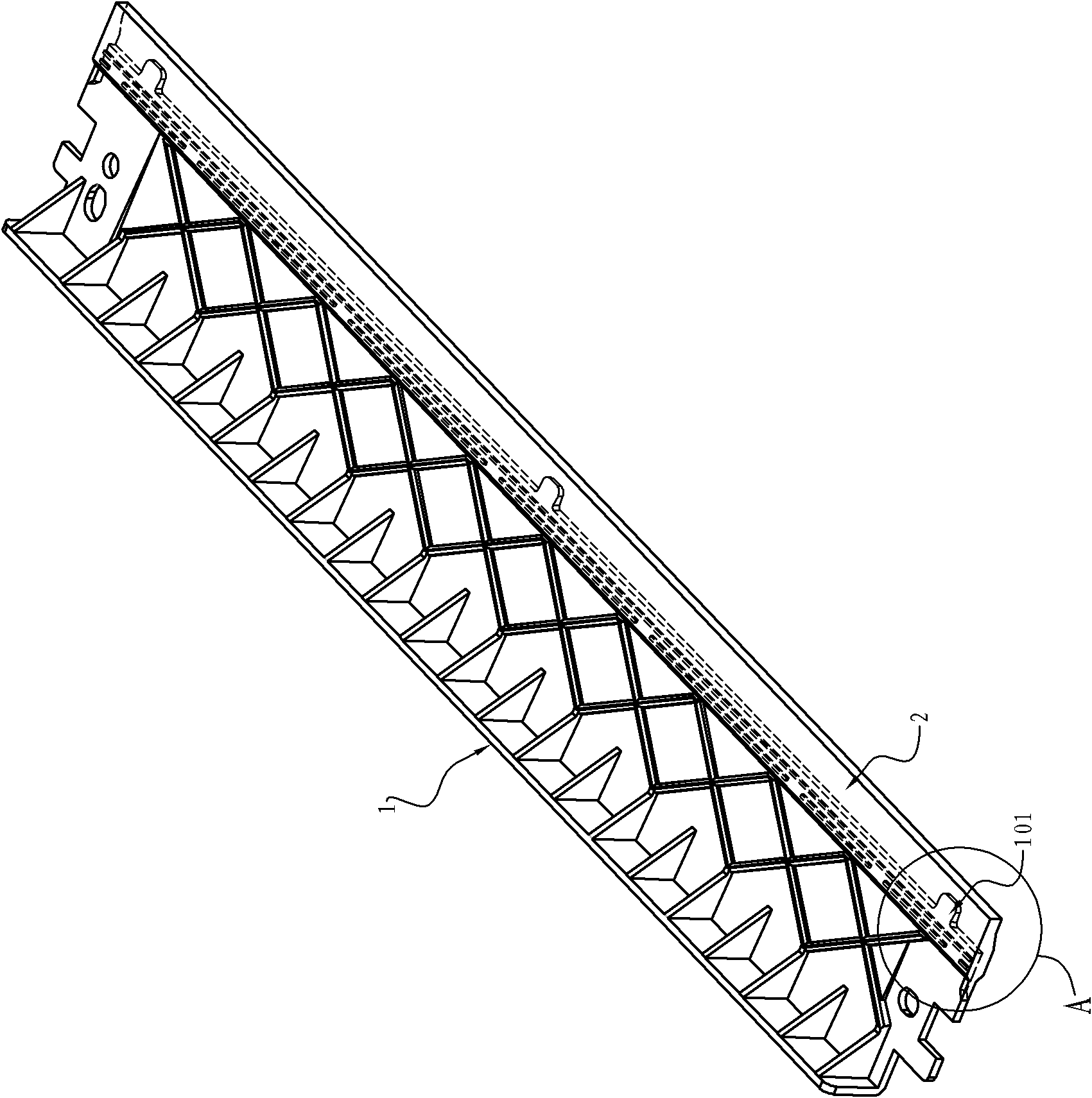

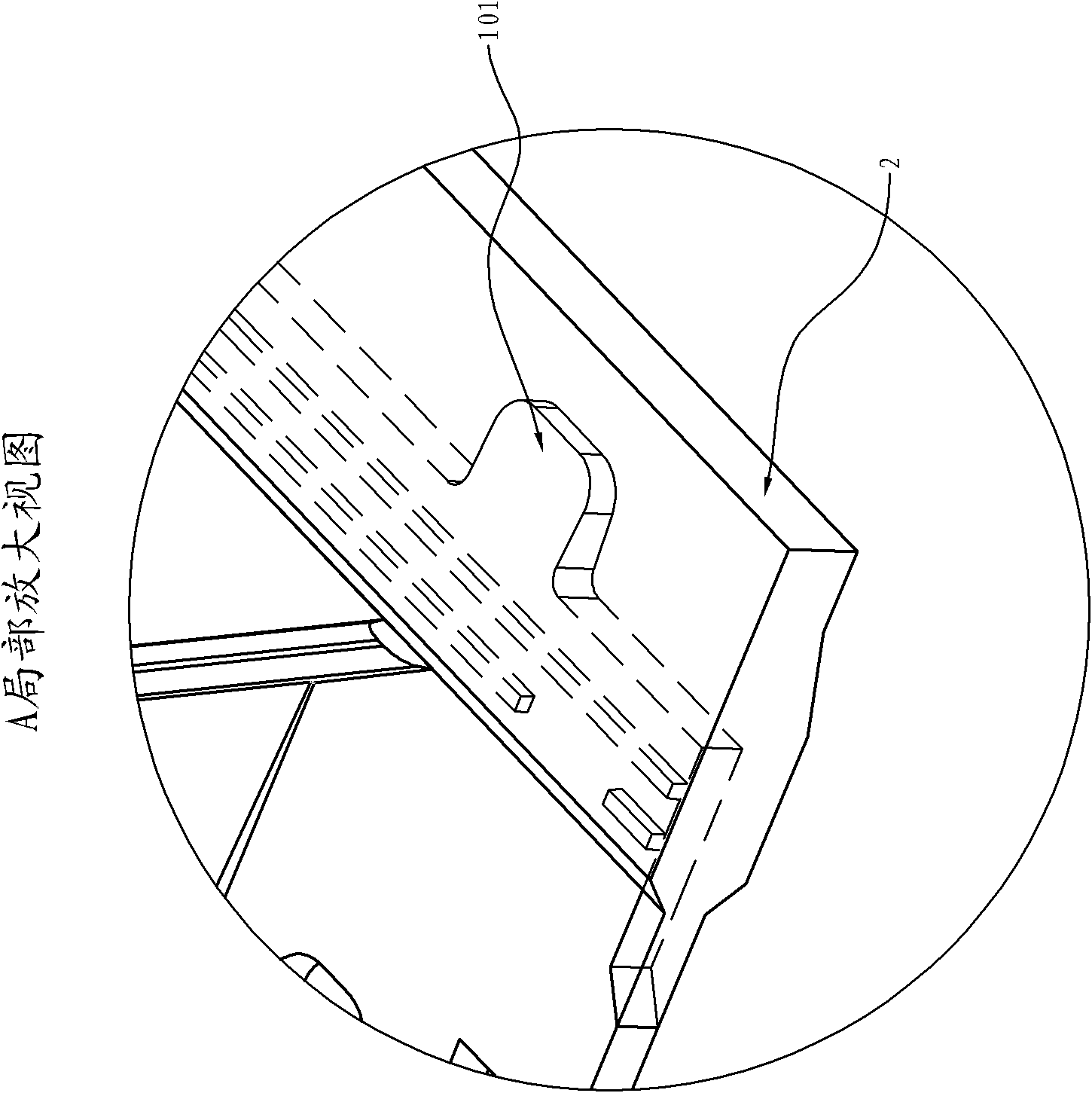

[0037] The mold of the clamping device is in accordance with figure 1 The structural design of two connected scrapers is shown. figure 1 The two scrapers shown in have the same structure, the edges 3 of the blades 2 of the two scrapers are aligned and connected together, the parallel blades 2 are located on the same plane, and the supporting end of each blade holder 1 is bent toward the same side of the blade 2 . The mold core on the movable mold and the fixed mold encloses two connected blade mold cavities and two knife holder mold cavities, wherein a movable mold core on the fixed mold fills the two connected blade mold cavities.

[0038] 2) Feeding

[0039] Add hard rubber to the hopper of the main injection device of the dual-material injection molding machine. The hard rubber can be glass fiber reinforced polyphenylene sulfide (PPS+GF), glass fiber reinforced polycarbonate (PC+GF) or polyparaphenyle...

no. 2 example

[0055] Scraper production method steps

[0056] 1) Mold preparation

[0057] Make a scraper mold, including a blade cavity and a knife holder cavity, the blade cavity and the knife holder cavity are surrounded by the movable mold of the mold and the core on the fixed mold, and there is a movable mold on the fixed mold The core fills the insert cavity.

[0058] 2) Feeding

[0059] Add hard rubber to the hopper of the main injection device of the dual-material injection molding machine. The hard rubber can be glass fiber reinforced polyphenylene sulfide (PPS+GF), glass fiber reinforced polycarbonate (PC+GF) or polyparaphenylene Any of butylenedicarboxylate (PBT). At the same time, add soft rubber to the hopper of the auxiliary injection device of the double-material injection molding machine. The soft rubber can be thermoplastic polyurethane elastomer (TPU) or polyamide resin (PA).

[0060] 3) Set injection molding parameters and inject a scraper

[0061] The parameter sett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com