Method for recycling waste lead storage battery

A technology for waste lead-acid batteries and lead-acid batteries, which can be used in battery recycling, recycling technology, recycling by waste collectors, etc., and can solve the problems of environmental pollution and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

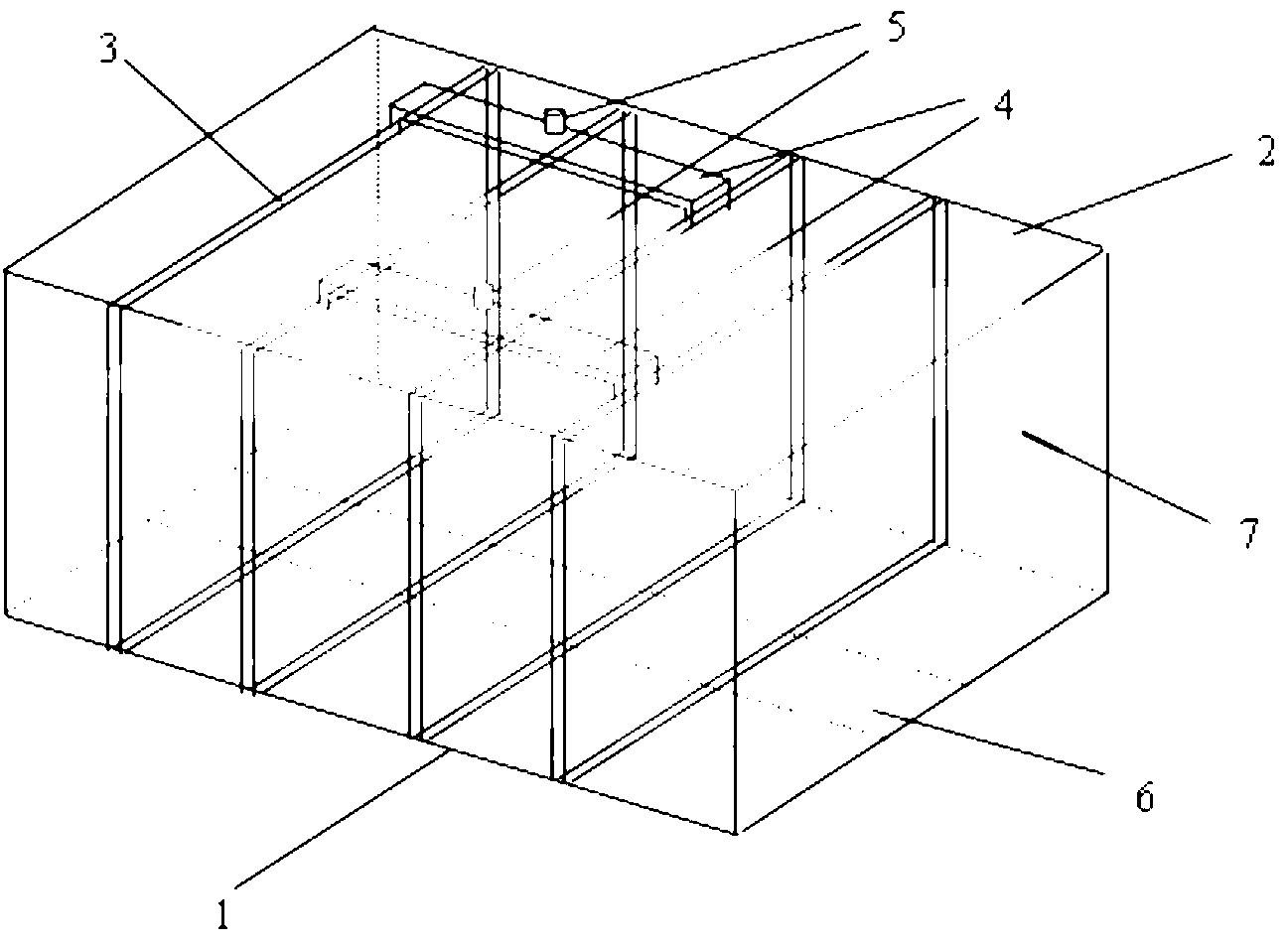

[0012] General lead-acid batteries are composed of plastic or hard rubber, lead, and sulfuric acid electrolyte. The battery tank 1, cover 2, and separator 3 are made of plastic or hard rubber, the pole plate 4, terminal 5, and bus bar 6 are made of lead, and the sulfuric acid electrolyte 7 is paste.

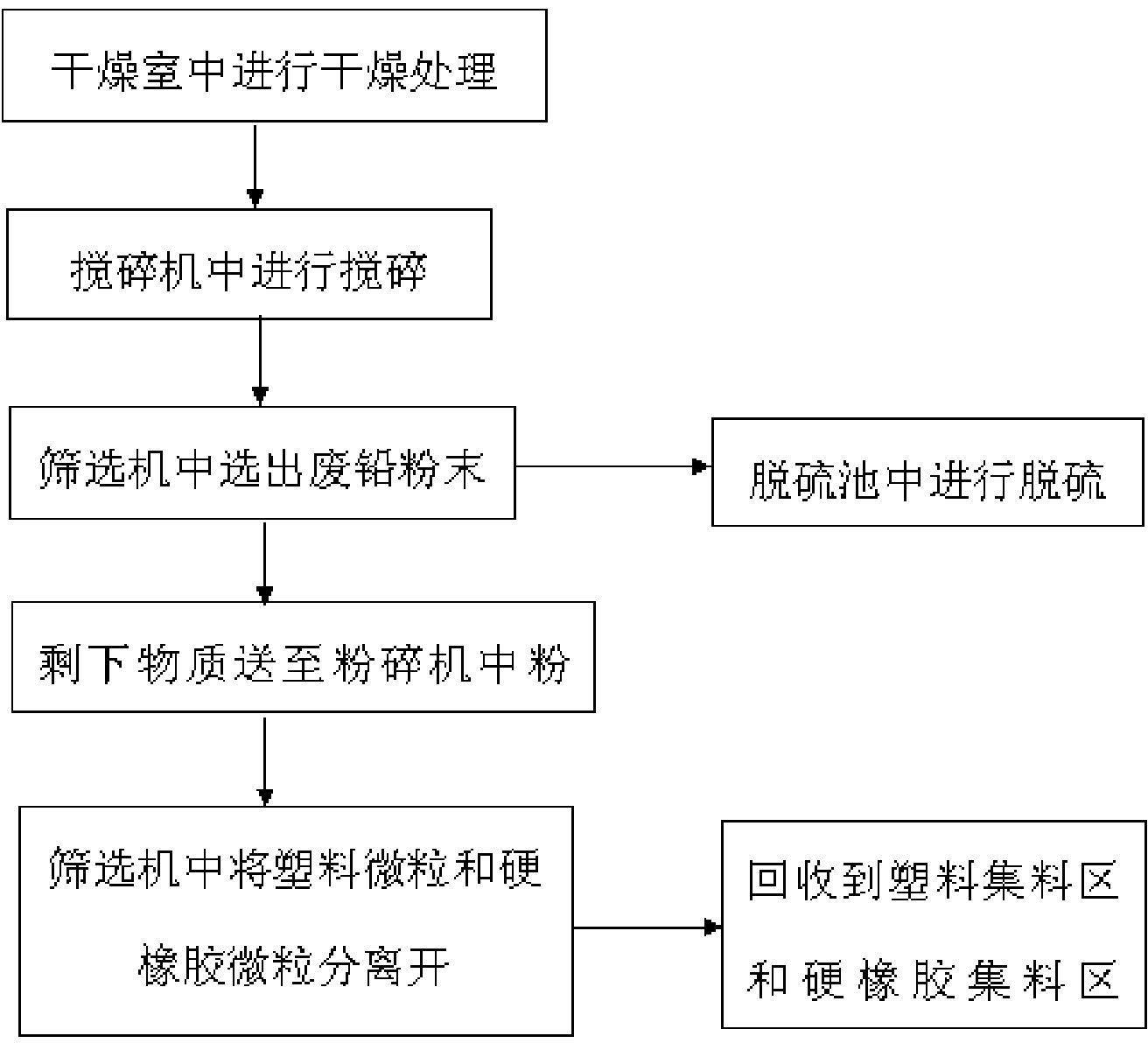

[0013] A method for recycling waste lead storage batteries, it comprises the following steps:

[0014] 1. Send the recovered waste lead-acid batteries to the drying room for drying treatment. According to the working principle of the lead-acid battery, water will be generated during the discharge process, and the drying here is convenient to separate the waste lead powder from the plastic or hard rubber particles in the subsequent crushing and screening process.

[0015] 2. Put the dried waste lead-acid batteries into the crusher for crushing, and at the same time, send the crushed materials to the screening machine to select the waste lead powder, and then put them in the desul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com