PDMS-based flexible implanted neural microelectrode and manufacturing method

A micro-electrode and implantable technology, applied in the direction of electrodes, internal electrodes, and pharmaceutical devices, can solve the problems of metal layer cracks, influence of electrode electrical characteristics and working effects, and unfavorable PDMS micro-electrode surgical implantation. Good mechanical properties, effects for safe implantation and efficient operation, good electrical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The features of the PDMS-based flexible implantable neural microelectrode of the present invention will be further described below in conjunction with the accompanying drawings.

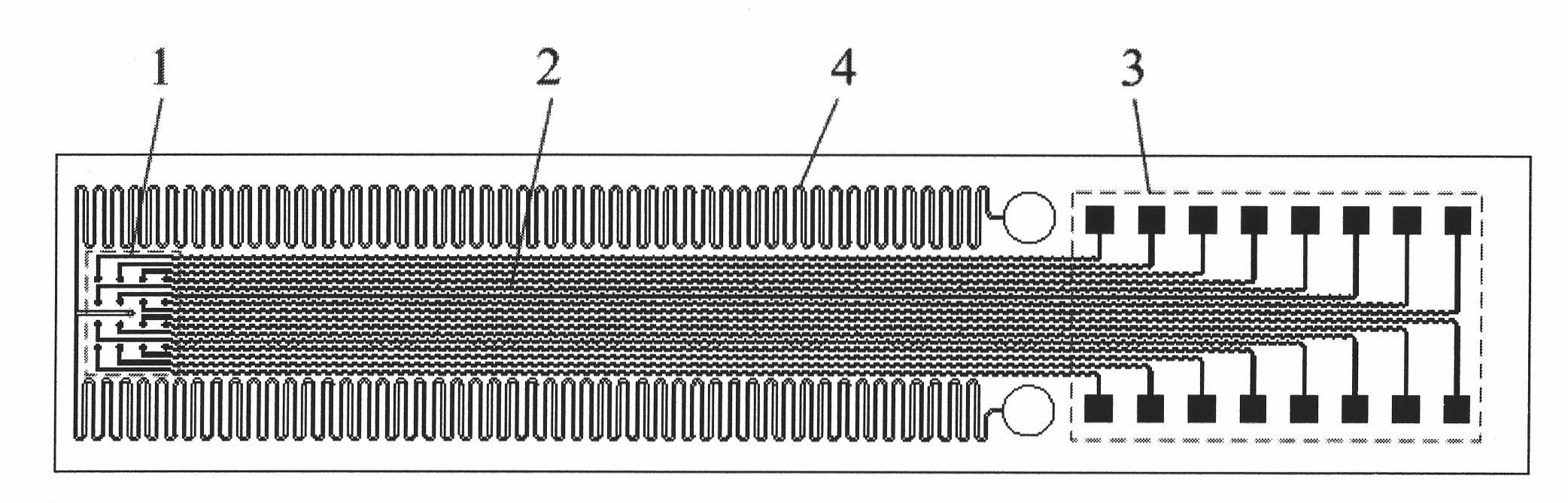

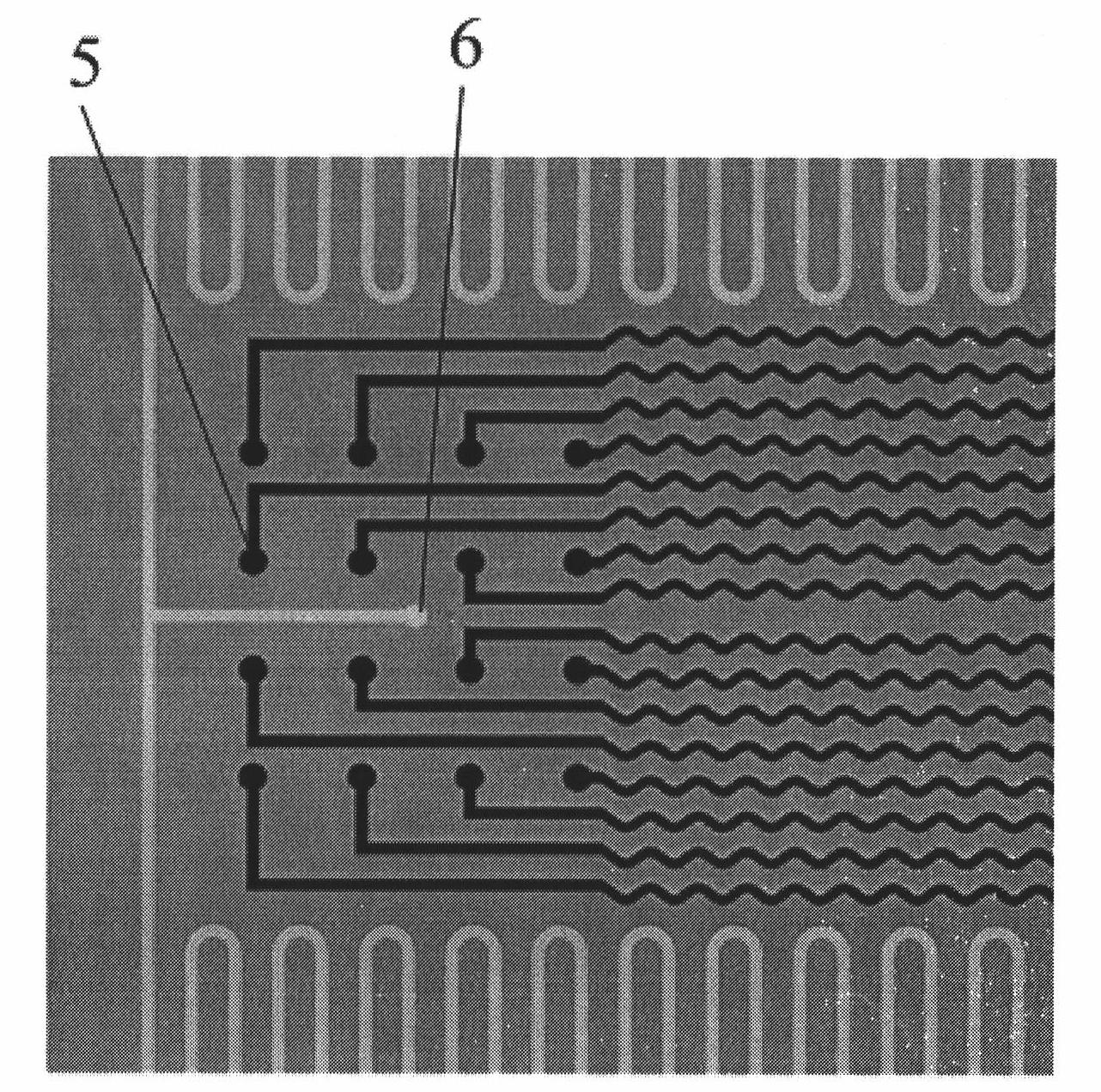

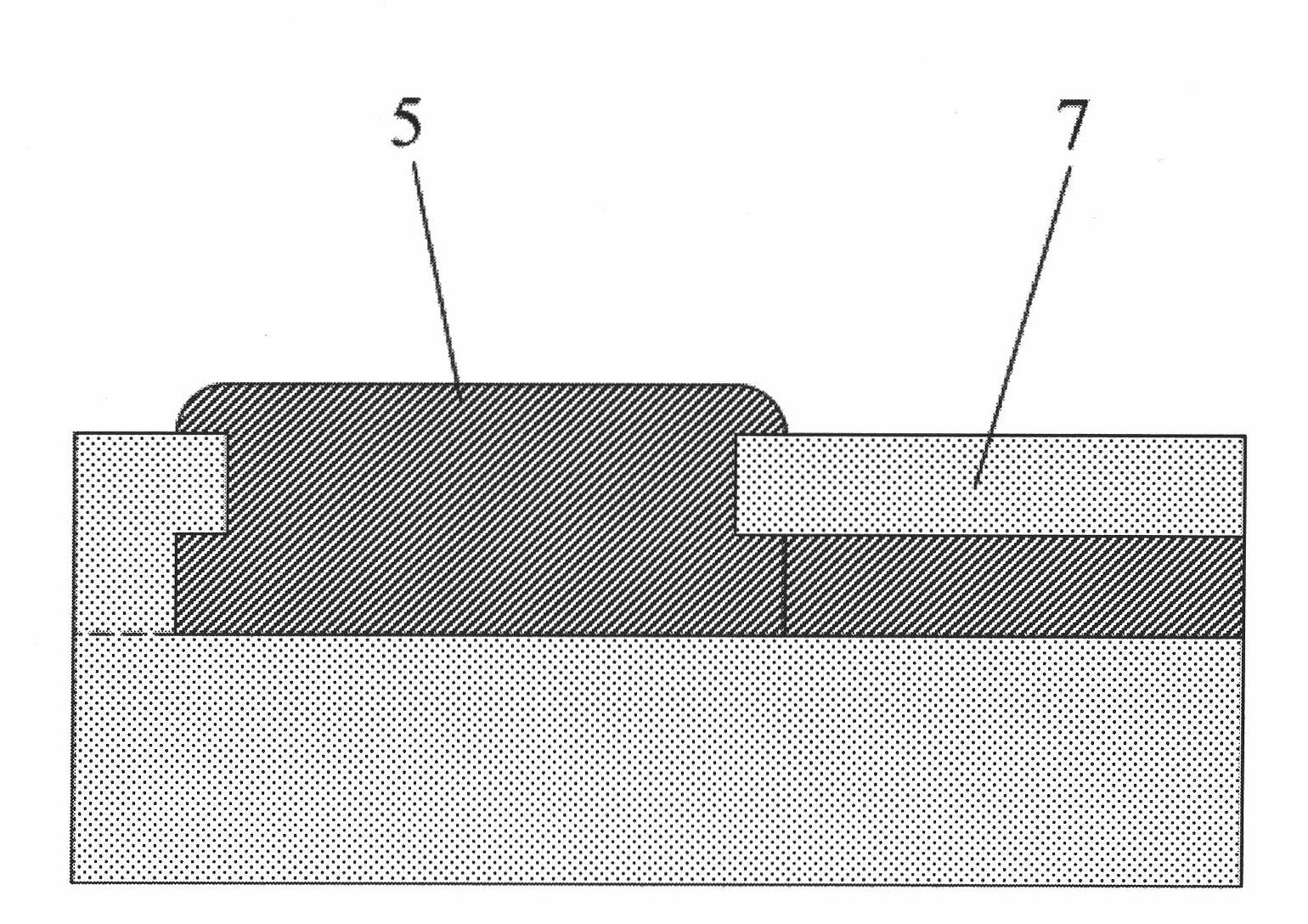

[0016] The PDMS-based flexible implantable neural microelectrodes provided by the present invention are as figure 1 As shown, it includes electrode site area 1, connection line area 2, welding point area 3 and micropipe area 4. The electrode site area 1 contains a plurality of metal electrode site arrays 5 and integrated microchannel openings 6 (such as figure 2 shown). The surface of each electrode site has smooth and convex features, and the longitudinal direction is a "dumbbell" three-section structure, and the cross-section of the upper and lower ends is larger than that of the middle section (such as image 3As shown), such a structure makes the metal structure clamp the PDMS film 7, so as to ensure that the metal structure will not be detached from the PDMS film during the subsequent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com