Wood-plastic composite material using sweet sorghum slag as enhanced phase and preparation method for wood-plastic composite material

A kind of wood-plastic composite material and composite material technology, applied in the field of wood-plastic composite material and its preparation, to achieve the effects of light weight, low processing temperature and fast extrusion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

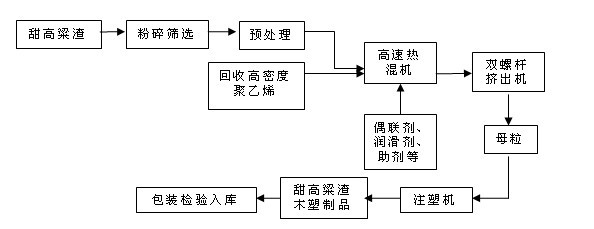

[0048] Preparation of sweet sorghum slag wood-plastic pots by injection molding process:

[0049] Formula: parts by weight

[0050]Sweet sorghum residue 30

[0051] Recycled HDPE 70

[0052] Maleic anhydride grafted PE 4

[0053] Polyethylene wax 5

[0055] Colorant 3

[0056] Antioxidant 1

[0057] Prepare sweet sorghum slag wood-plastic pots by injection molding process according to the above formula. The specific process is: crush the sweet sorghum slag, screen out 60-120 mesh sweet sorghum slag powder, and combine the alkali-oxygen method with the steam explosion method. preprocessing. The pretreated sweet sorghum slag and recycled plastics are hot-mixed and dried, and then various proportions of coupling agents, lubricants, and additives are added, and extruded and granulated by a twin-screw extruder to obtain sweet sorghum slag wood-plastic masterbatch. Then the sweet sorghum slag wood-plastic basin is obtained by injection molding wit...

Embodiment 2

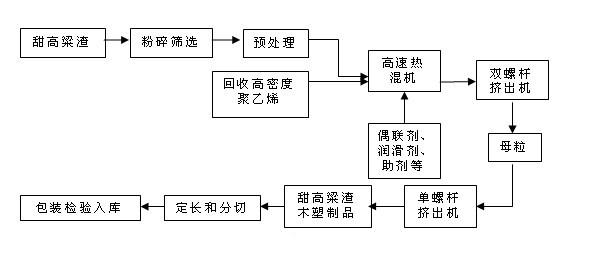

[0060] Preparation of sweet sorghum slag wood-plastic four-hole plate by extrusion molding:

[0061] Formula: parts by weight

[0062] Sweet sorghum residue 70

[0063] Recycled HDPE 30

[0064] Maleic anhydride grafted PE 4

[0066] Polyethylene wax 5

[0068] Colorant 3

[0069] Antioxidant 1

[0070] Flame retardant 3

[0071] Sweet sorghum slag wood-plastic four-hole plate was prepared by extrusion molding process according to the above formula, wherein the antioxidant was antioxidant 168, and the flame retardant was Mg(OH) 2 or Al(OH) 3 or a mixture thereof. The specific process is as follows: pulverize the sweet sorghum slag, screen the sweet sorghum slag powder of 60-120 mesh, and carry out combined pretreatment of alkali-oxygen method and steam explosion method on it. The pretreated sweet sorghum slag and recycled plastics are hot-mixed and dried, and then different proportions of fillers, coupling a...

Embodiment 3

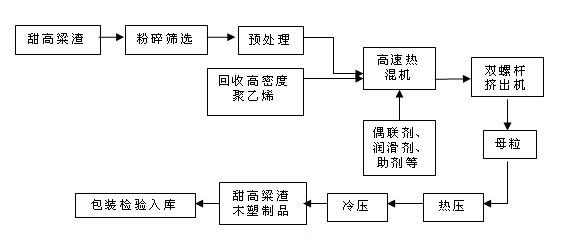

[0073] Sweet sorghum slag wood-plastic wall prepared by extrusion molding process:

[0074] The difference between this embodiment and embodiment 2 is that the extrusion die is a large cross-section die with a cross-sectional appearance size of 600mm×120mm (length×width), and the rest are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Flexural modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com