Spinning forming method and device based on laser heating

A technology of laser heating and spinning forming, which is applied in the field of metal plastic processing, can solve problems affecting the service life of process equipment and spinning equipment, complex structure of forming process equipment, uneven temperature field of spinning parts, etc., and achieve easy automation , improve the service life, low labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

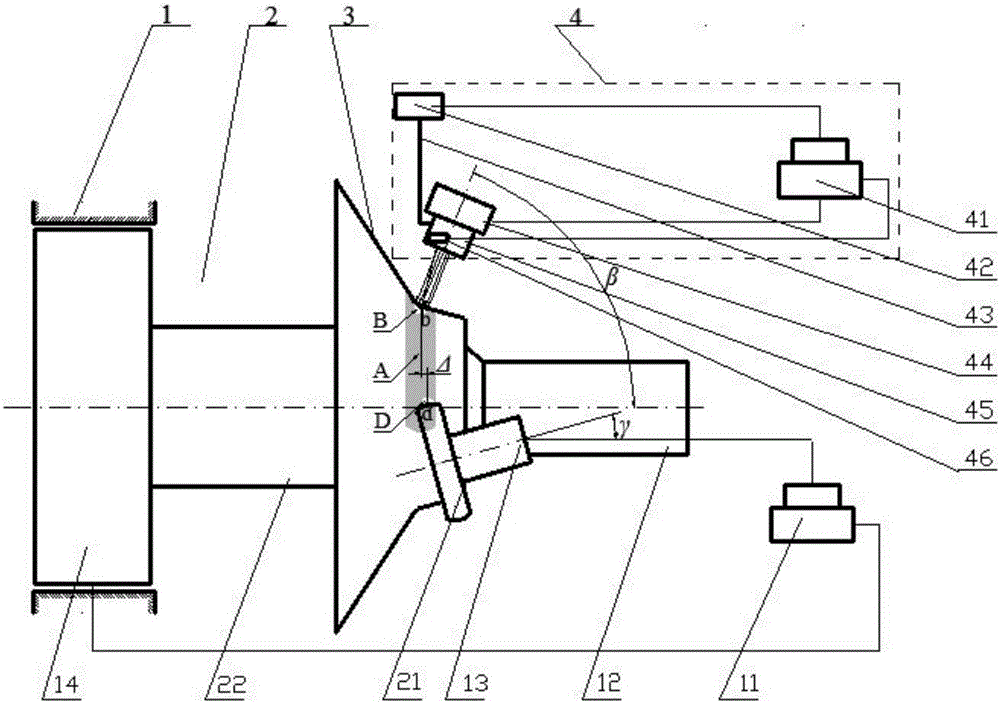

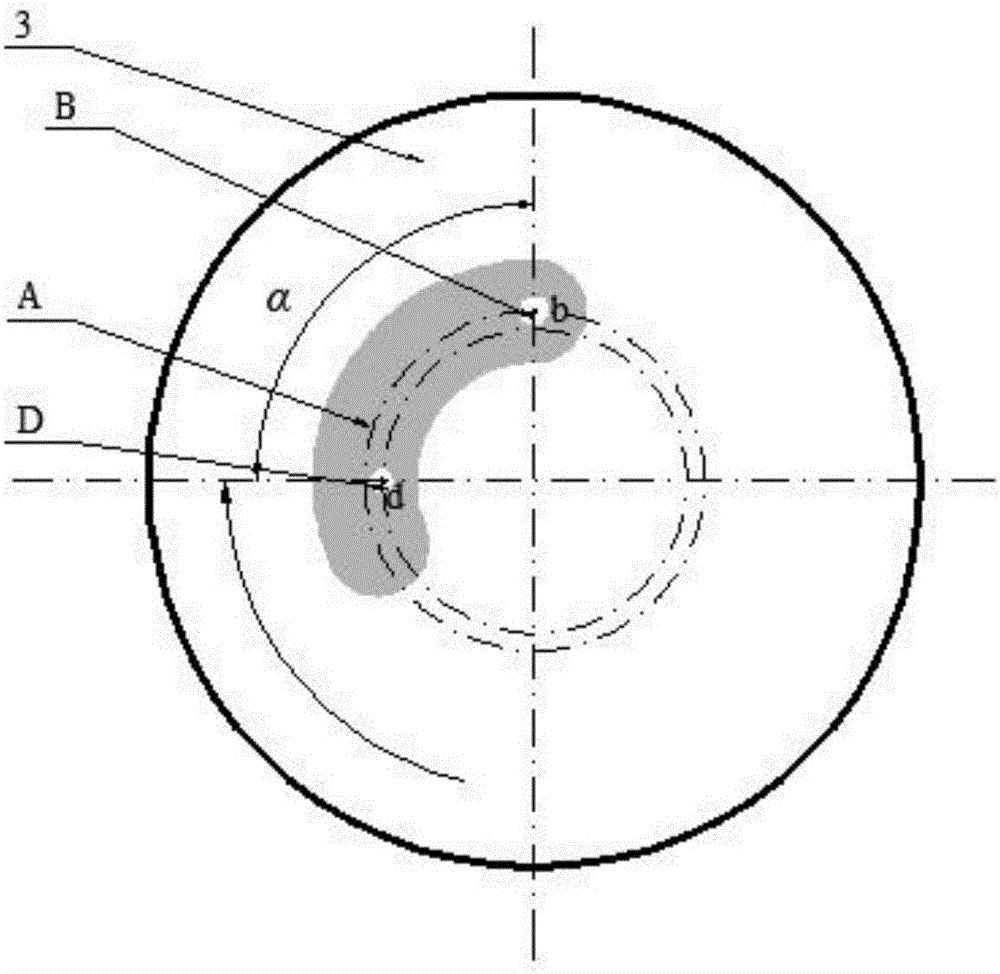

[0059] Example 1: Flow spinning of AZ31 magnesium alloy

[0060] AZ31 magnesium alloy cannot be shaped at room temperature, it needs to be heated to 200-350°C before spinning, and it is easy to oxidize, and has low absorption rate of laser; flow spinning is also called strong spinning of cylindrical parts, and the cylindrical parts The wall thickness is given by the initial value t 0 Thinning until the workpiece wall thickness is t workpiece, the shape does not change, and the forming is mostly processed in the form of multiple rollers (the rollers are evenly distributed along the circumferential direction), and the double-rotor or three-rotor method is often used in production; the forming process Including forward and reverse rotation. In this example, the anti-spinning process (adding chuck 23 to the spinning process equipment) is used to spin the workpiece with an initial wall thickness of 3.5mm and a length of 40mm into a workpiece with a wall thickness of 1.5mm and a le...

Embodiment 2

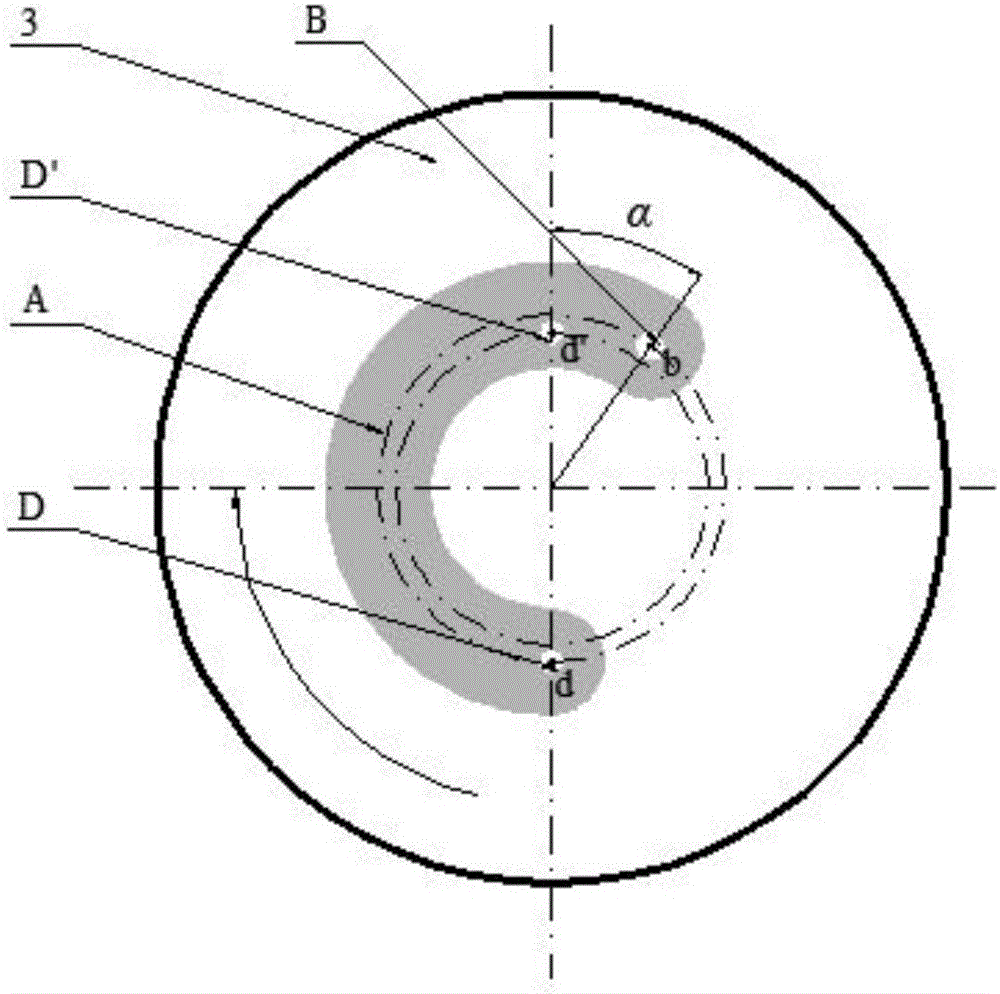

[0069] Example 2: 0Cr18Ni9 stainless steel single-pass deep drawing and spinning

[0070] The difference from Example 1 is:

[0071] The forming process is deep drawing and spinning, and the wall thickness t 0 A circular flat plate with a thickness of 1.6 mm is spun into a cup-shaped piece with a wall thickness t of 1.6 mm, that is, the wall thickness remains unchanged but the shape changes, and the forming is performed by a single rotary wheel 21 at the same time.

[0072] The forming material is 0Cr18Ni9 stainless steel, which is austenitic stainless steel and has good plasticity at room temperature, but martensite is easily induced during the deformation process, resulting in cracking. When processing at room temperature, it is advisable to use multi-pass spinning to reduce the influence of strain-induced martensite. In order to reduce the influence of work hardening, it is necessary to increase the annealing process between passes; The forming accuracy is poor.

[0073]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com