Self-piercing riveting device of ultrahigh strength steel plates or/and aluminum alloy plates

An aluminum alloy plate, self-piercing riveting technology, applied in the field of processing equipment, to achieve the effect of avoiding cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

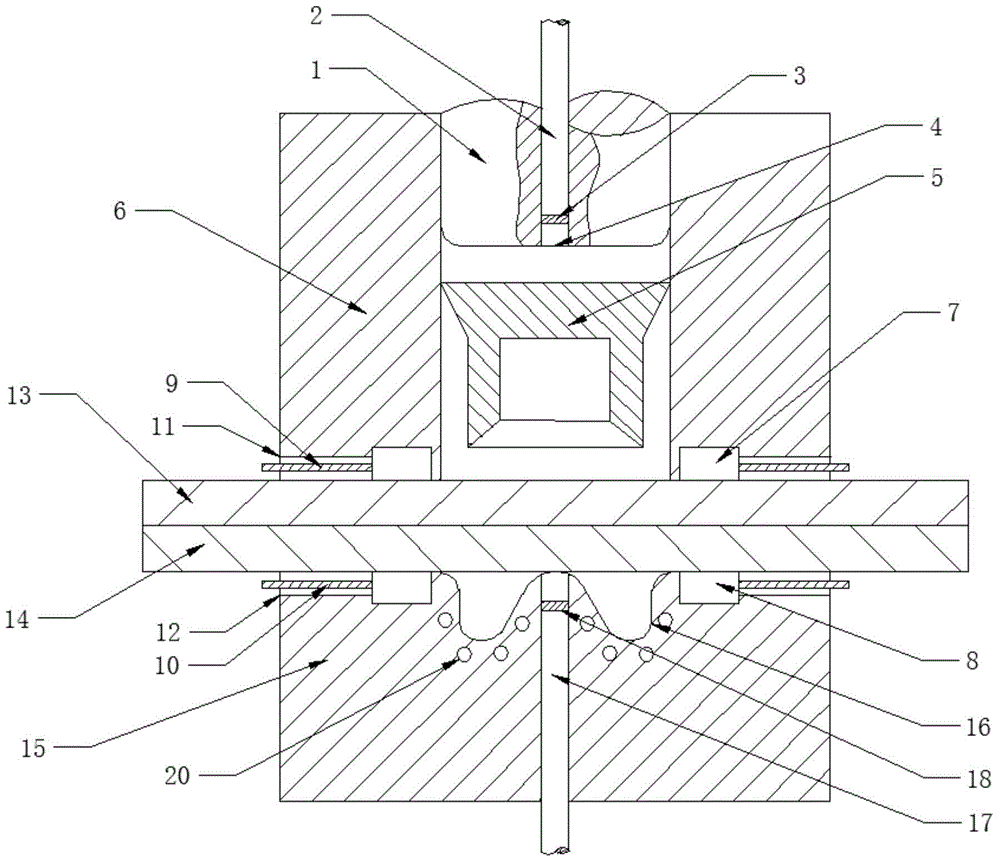

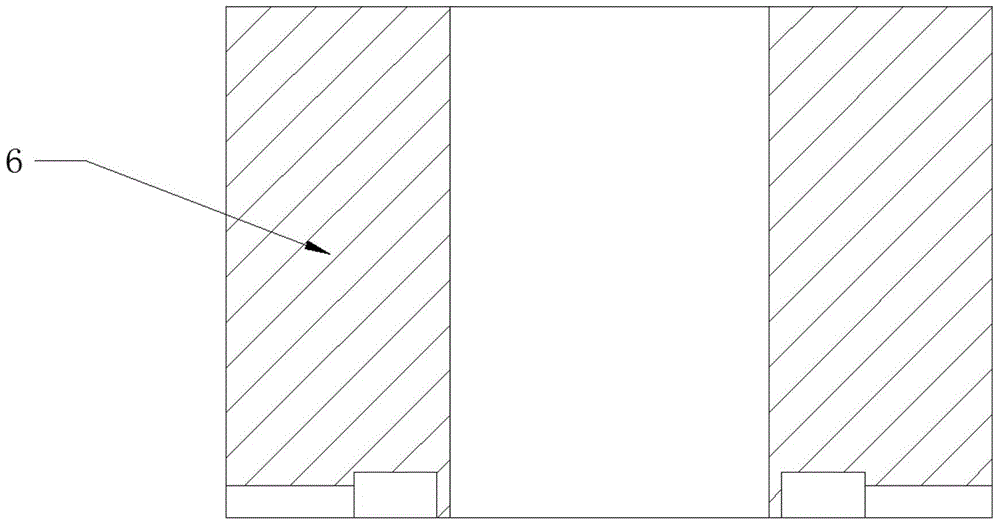

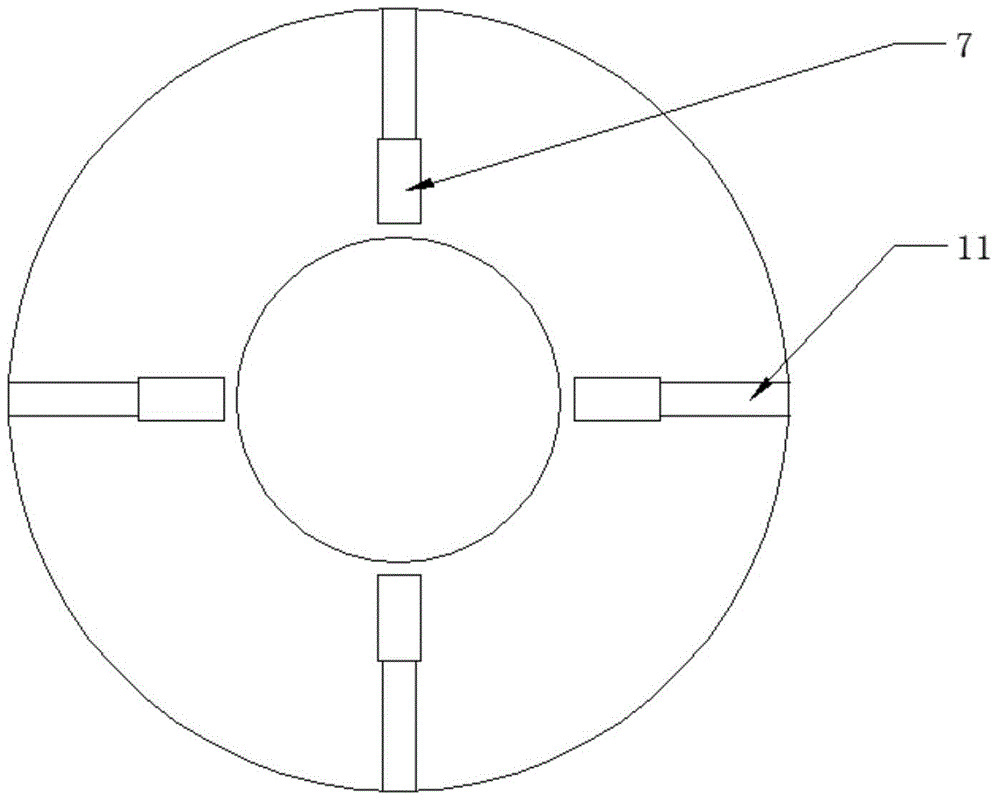

[0052] refer to figure 1 The self-piercing riveting device between ultra-high-strength steel plates or aluminum alloy plates according to the present invention includes a composite punch 1 (including a first optical fiber tube 2 and a first concave lens 3), a composite blank holder 6 (including 2 to 4 Thermistor with the same structure), composite concave mold 15 (second optical fiber tube 17, second concave lens 18, thermistor).

[0053] Composite binder ring 6 and composite die 15 are stacked up and down, composite punch 1 is put into the central hole of composite binder ring 6, and the rotation axes of composite binder ring 6, composite punch 1 and composite die 15 are Lines are arranged coaxially.

[0054] The first optical fiber tube 2 is connected with the first hollow circular hole 4 on the composite punch 1 by threads, the bottom end of the first optical fiber tube 2 is arranged with a first concave lens 3, and the bottom surface of the first concave lens 3 is far fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com