Method and device for forming plastic part microstructure based on laser heating

A microstructure forming and laser heating technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as difficulty in meeting the forming and processing requirements of plastic microstructure parts, and no strict temperature requirements, and achieve laser energy utilization efficiency. High, flexible processing, simple and practical system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

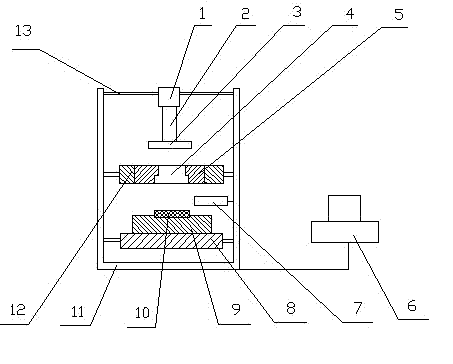

[0039] Example 1: Laser Heating Extrusion Forming of Microfluidic Chips

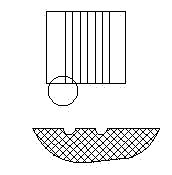

[0040] The microfluidic chip is a PMMA matrix sheet, and there are microchannels on the surface of the PMMA matrix, such as figure 2 As shown, the size of the substrate: 10×10×1mm, the microchannel is semicircular, the diameter is 0.1mm, and the distance between the microchannels is 0.5mm. Firstly, the ordinary injection mold is used to form the PMMA matrix sheet, and then the matrix is subjected to laser-heated plastic microstructure forming processing, that is, the microstructure forming process is completed by a laser heating extrusion forming device. Start the control system of the laser heating extrusion forming device, and set work instructions and procedures. Turn on the laser, adjust the optical system; determine the main parameters of the laser: power 10W, positioning irradiation time 0.05s. The base of the upper and lower parts of the microstructure extrusion molding system is separated, a...

example 2

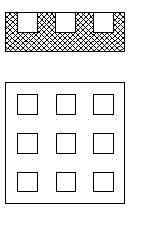

[0041] Example 2: Laser Heating Extrusion Forming of Cell Culture Dish

[0042] The cell culture dish is made of PS material, and the surface of the cell culture dish has microstructures such as image 3 As shown, the size of the matrix is 1.2×1.2×0.5mm, the size of the square microholes is 0.2×0.2×0.3mm, and a total of 9 square microholes are arranged in an array. Firstly, the matrix of the cell culture dish is obtained by injection molding, and then the plastic microstructure forming process is carried out by laser heating. Start the control system of the laser heating extrusion forming device, set the work order and program, turn on the laser, adjust the optical path system; determine the main parameters of the laser: power 2W, spot diameter 5mm, and irradiation time for each positioning 0.1s. The base of the upper and lower parts of the microstructure extrusion molding system is separated, and the unloader takes the base of the cell culture dish and places it on the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com