Large support roller overlaying workstation and operation method thereof

A technology of supporting rollers and workstations, which is applied in the direction of manufacturing tools, welding equipment, welding equipment, etc., can solve the problems of difficult surfacing welding repair work, prone to cracks on the supporting rollers, and difficult to reach the welding temperature, etc., to achieve continuous and stable welding process , The effect of small rotating torque and large starting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

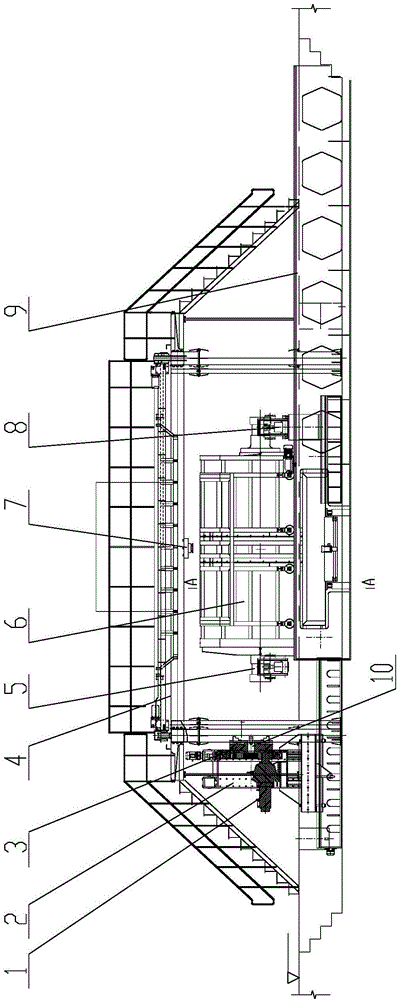

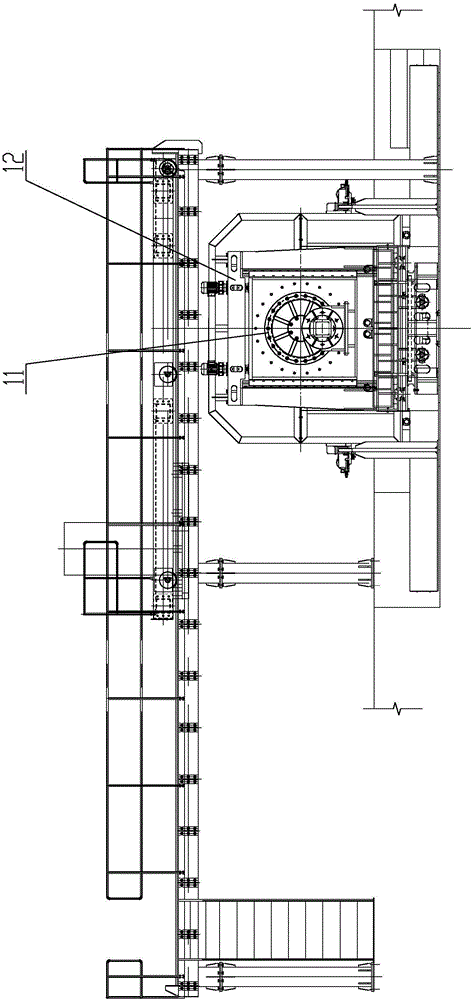

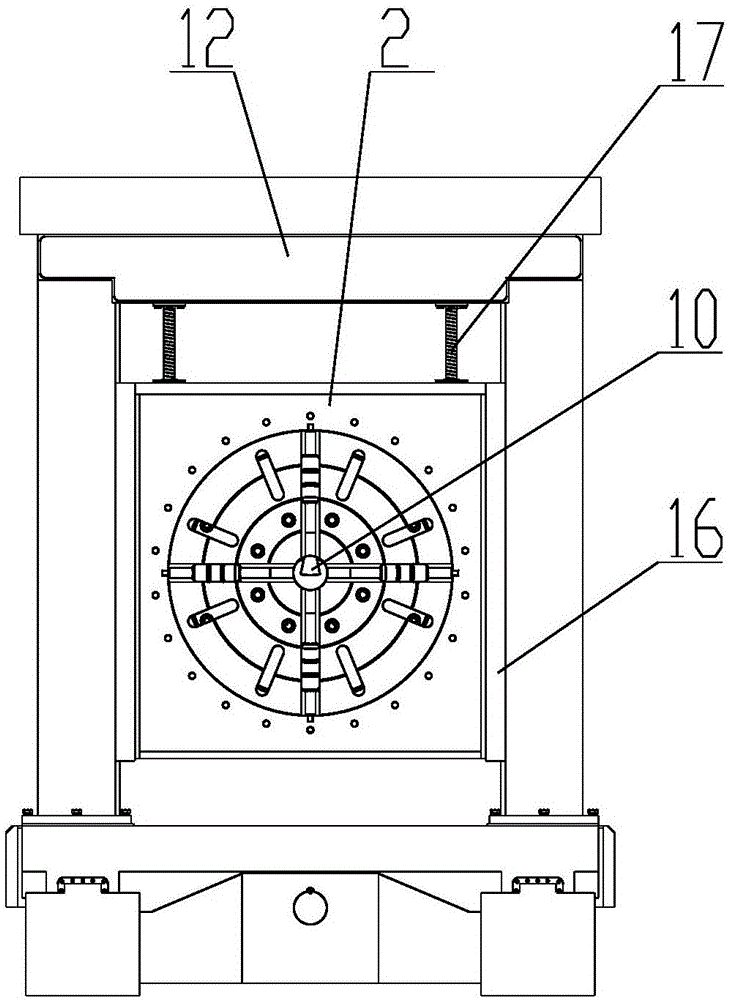

[0044] See Figure 1-Figure 2 Shown is a schematic structural view of a large backup roller surfacing workstation according to the present invention. A large-scale supporting roller surfacing welding workstation according to the present invention includes a roller supporting device, a roller driving device, an online heating system, a welding system, and a flux recovery system. The supporting roller 5 is supported and positioned by the roller supporting device, and can be positioned on the Driven to rotate; the online heating system includes a door-type heating cover 6, which covers the outside of the support roller 5 to form a closed cover, and the inner wall of the cover is provided with a thermal insulation layer 31 and an induction electric heating device 27. Thermocouple 28, welding torch inlet 21 is arranged on the top of the cover body; we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com