Preparation method of titanium-steel composite plate thin strip

A composite plate and thin strip technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of micro-cracks and oxide inclusions, incomplete melting of spray powder particles, surface coating pores, etc., to eliminate Coating holes, improved bonding strength, increased bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

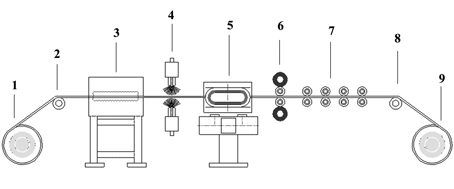

Image

Examples

Embodiment 1

[0014] First, uncoil the 2mm thick austenitic stainless steel strip, send it into the heating furnace and heat it to 50°C; then enter the spraying section continuously, and spray pure titanium powder on the upper and lower surfaces of the stainless steel strip to form Nistenitic stainless steel as the matrix, two layers of 0.01mm thick pure titanium clad stainless steel-pure titanium composite plate thin strip; cooled to room temperature in the air; then the sprayed plate thin enters the online rapid heating device HOP (Heat-treatment Online Process), the clad sheet is heated for 4s to 200°C, and then enters the finishing mill, the total rolling reduction rate is 50%, and the clad sheet is rolled into a composite sheet with a total thickness of 1.01mm at a rolling speed of 1m / s. Plate and thin strip, wherein the middle layer of stainless steel is 1mm thick, and the upper and lower layers of pure titanium are 0.005mm thick. Finally, the thin strip of the clad plate is coiled to...

Embodiment 2

[0016] Firstly, the 3mm thick austenitic stainless steel strip is uncoiled and sent into the heating furnace to be heated to 220°C; then it enters the spraying section continuously, and the upper and lower surfaces of the stainless steel strip are thermally sprayed with pure titanium powder to form an austenitic stainless steel strip. Nistenitic stainless steel as the substrate, two layers of 0.1mm thick pure titanium-coated stainless steel-pure titanium composite plate thin strip; cooled to room temperature in the air; then the sprayed plate thin enters the online rapid heating device HOP (Heat-treatment Online Prcess), heat the clad sheet for 4s to 750°C, then enter the finishing mill, the total rolling reduction rate is 50%, and roll the clad sheet at a rolling speed of 2m / s to form a composite sheet with a total thickness of 1.6mm. Plate and thin strip, wherein the middle layer of stainless steel is 1.5mm thick, and the upper and lower layers of pure titanium are 0.05mm thi...

Embodiment 3

[0018] Firstly, the 4mm thick austenitic stainless steel strip is uncoiled and sent into the heating furnace to be heated to 700°C; then it enters the spraying section continuously, and the upper and lower surfaces of the stainless steel strip are thermally sprayed with pure titanium powder to form an austenitic stainless steel strip. 2mm thick stainless steel-pure titanium clad strip; cooled to room temperature in the air; then the sprayed plate enters the online rapid heating device HOP (Heat-treatment Online Process ), heat the clad sheet for 4s to 1000°C, and then enter the finishing mill with a total rolling reduction of 50%, and roll the clad sheet at a rolling speed of 0.3m / s to make a clad sheet with a total thickness of 4mm A thin strip, wherein the middle layer of stainless steel is 2mm thick, and the upper and lower layers of pure titanium are 1mm thick. Finally, the thin strip of the clad plate is coiled to obtain a thin strip of titanium-steel clad plate with an i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating thickness | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com