Alignment film precuring equipment

A pre-cured, oriented film technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

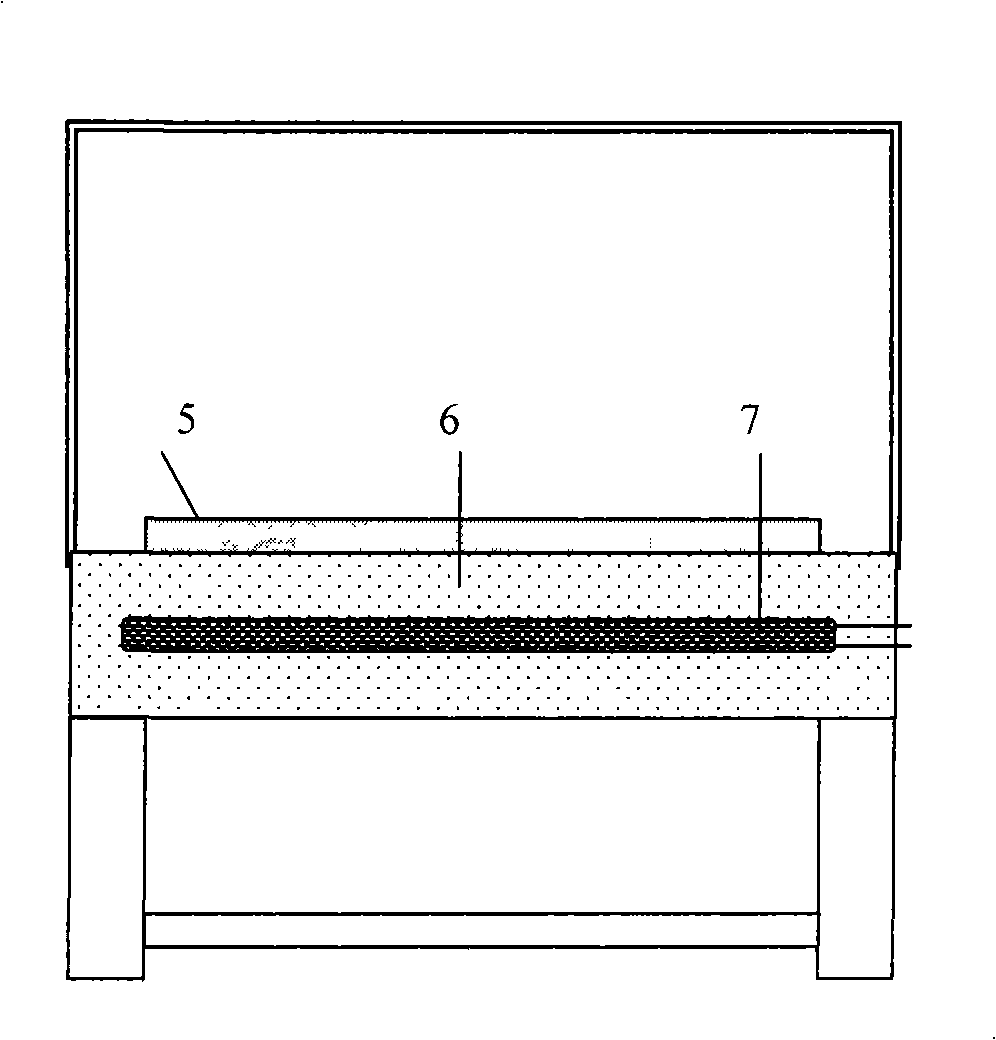

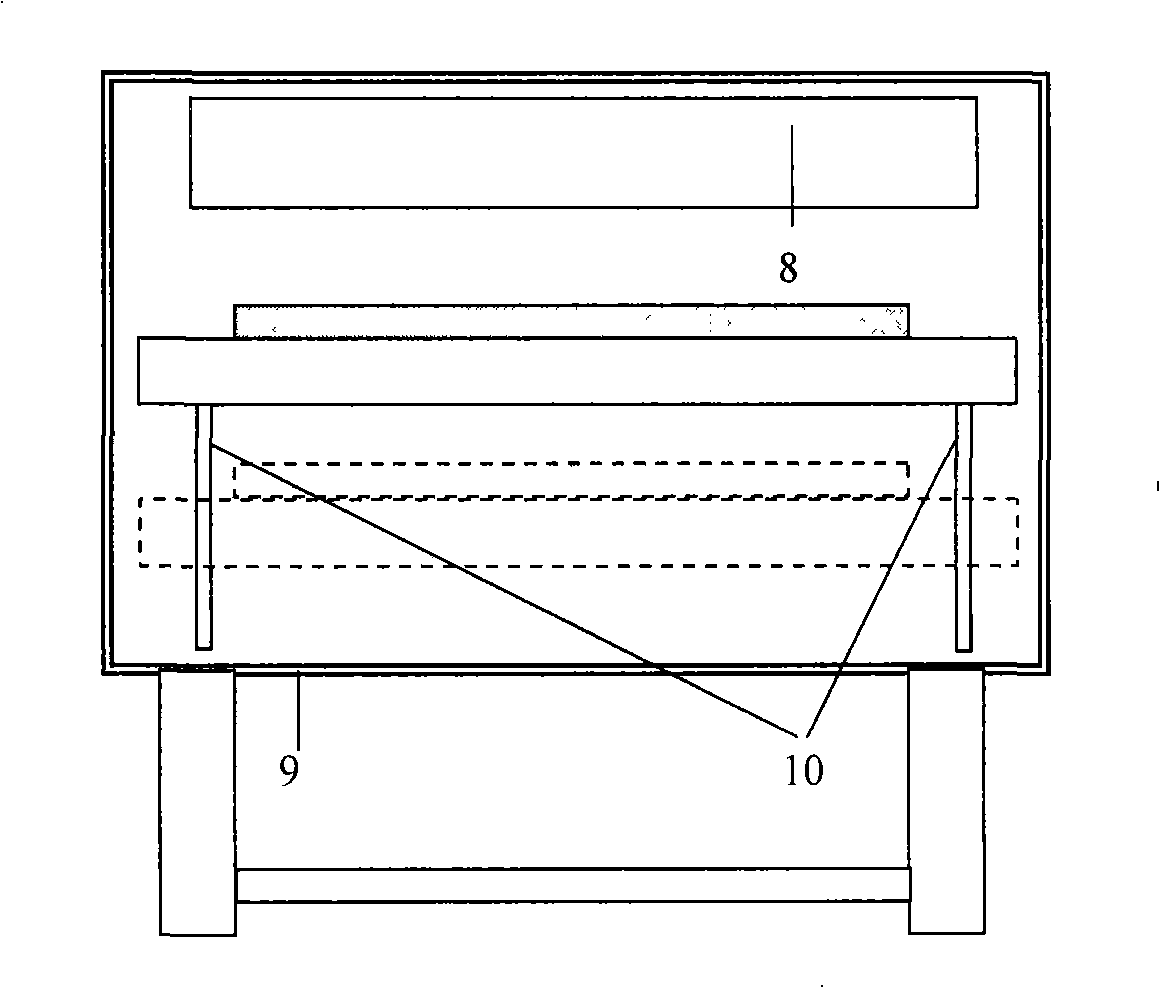

[0017] figure 2 A schematic diagram of the curing of the alignment film on the substrate by the alignment film pre-curing equipment of the present invention is shown. Such as figure 2 Therefore, when the alignment film in this embodiment is solidified, the substrate 5 coated with the alignment film is placed on the top of the new workbench 9, an infrared generator 8 is arranged above the glass substrate, and the infrared generator 8 generates infrared rays, and the substrate 5 is For radiant heating, the new workbench 9 can move up and down along the slide rail 10. When the heating starts, the distance between the new workbench 9 and the infrared generator 8 on the upper part of the equipment is relatively far (the position shown by the dotted line in the figure), and the substrate 5 is less heated ; During the heating process, the new workbench 9 rises automatically, and the distance between the new workbench 9 and the infrared generating device 8 on the upper part of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com