Hot roller heating and rolling device and method for magnesium alloy strips

A magnesium alloy and strip technology, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of high energy consumption for rolling gap annealing, low off-line heating efficiency of heating furnace, low plastic deformation capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings and examples. The following examples are only used to more clearly illustrate the technical solutions of the present invention, and cannot be used to limit the protection scope of the present invention.

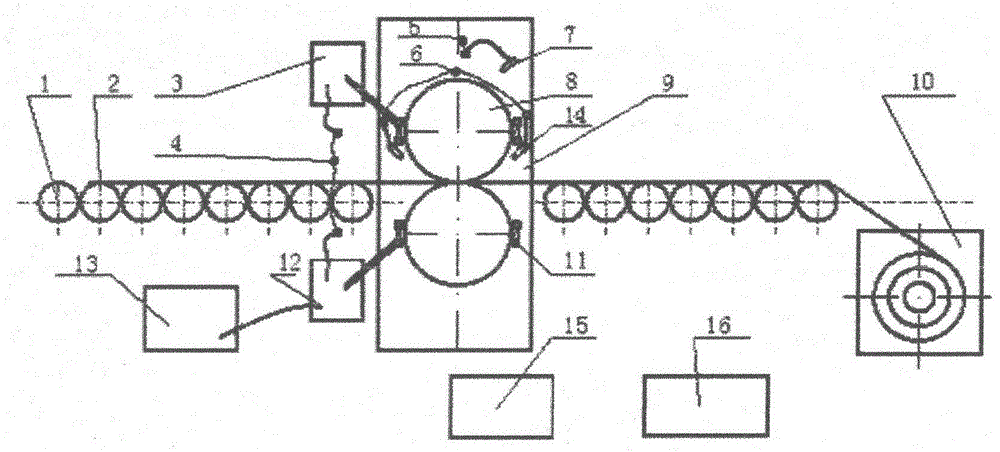

[0054] like figure 1 As shown, it is a schematic structural diagram of an embodiment of the present invention. One of the technical subjects of the present invention relates to a magnesium alloy strip hot roll heating and rolling device, which includes:

[0055] Transport roller table 1, the transport roller table 1 consists of at least one transport roller;

[0056] at least one rolling mill stand 9, the rolling mill stand 9 is arranged on the transport roller table 1;

[0057] at least one group of rolls 8, the rolls 8 are arranged on the rolling mill stand 9, and the magnesium alloy strip 2 to be rolled is arranged between the rolls 8;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com