On-line detection method for line heating forming

A detection method and measurement method technology, which is applied in the field of shipbuilding technology and optical measurement, can solve the problems of increased cost of CMM measurement range, low measurement efficiency, waste of wood, etc., to reduce technical requirements and labor intensity, high detection efficiency and precision , the effect of improving speed and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

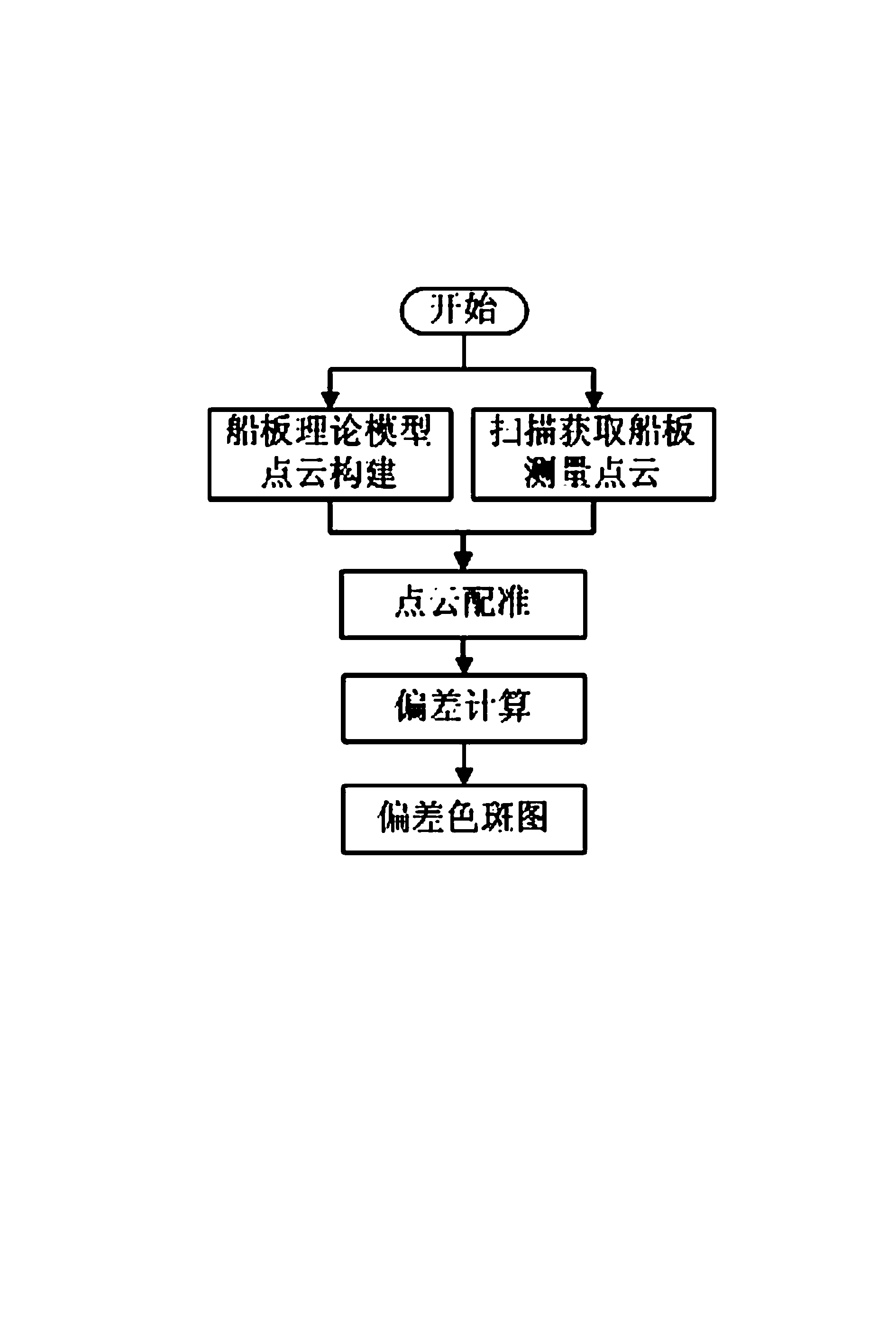

[0021] Combine below figure 1 The flow chart of the curved surface detection method further describes the specific implementation of the present invention.

[0022] A. According to the boundary and characteristic lattice of the ship plate, the uniform point cloud of the theoretical model of the ship plate is constructed and the surface is fitted .

[0023] From design software (such as: Tribon ) to derive the contour point sequence of the theoretical surface of the ship plate and the three-dimensional coordinates of the uniformly distributed lattice on it .

[0024] (1) Will Towards Surface Projection Generating Lattice , sympathetic to Surface Projection Generating Lattice ,Towards Surface Projection Generating Lattice ;

[0025] (2) Fit spline ;

[0026] Fit spline ;

[0027] Fit spline ;

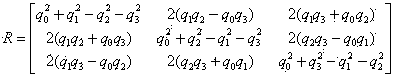

[0028] (3) For a point on the surface of the ship plate ,A known beg

[0029] exist According to:

[0030] can be solved for a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com