Device and method for producing high-frequency roll welding multilayer composite plate

The invention relates to a production device and a technology for clad plates, which are applied in the field of steel processing and manufacturing, and can solve the problems of increasing the difficulty and production time of metal clad plates, reducing the production efficiency of metal clad plates, and not being able to continuously process sheet materials, thereby reducing production costs, The effect of improving production efficiency and simple and convenient process adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

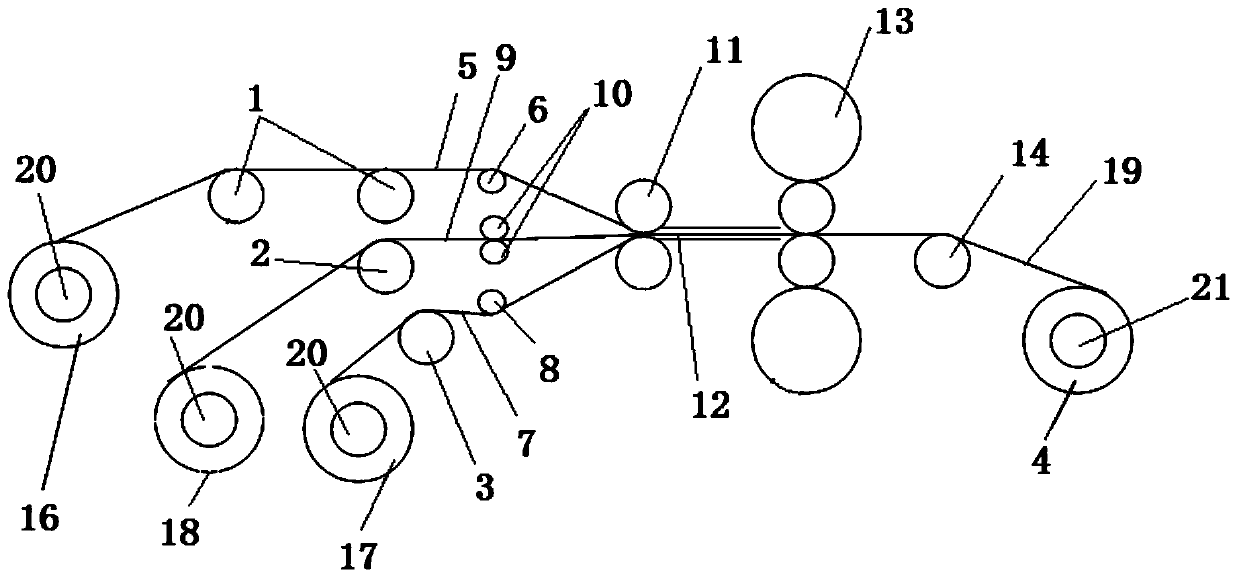

[0042] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

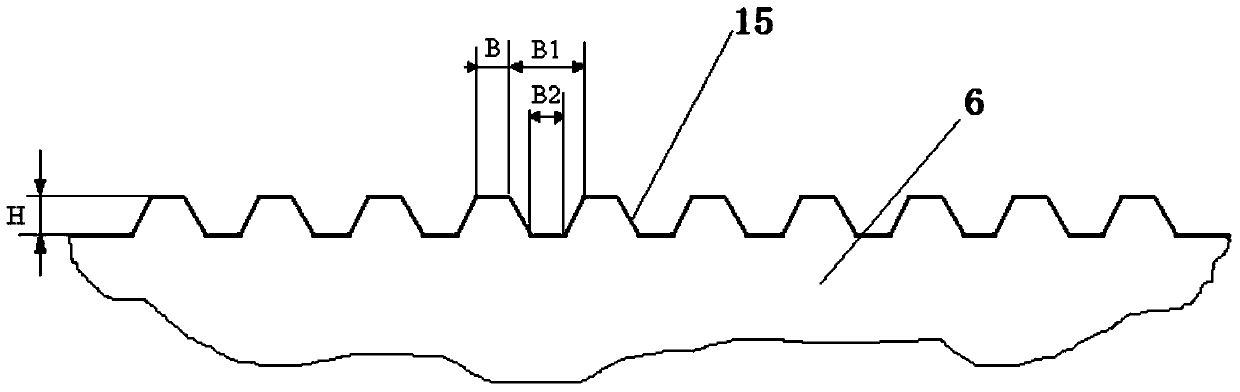

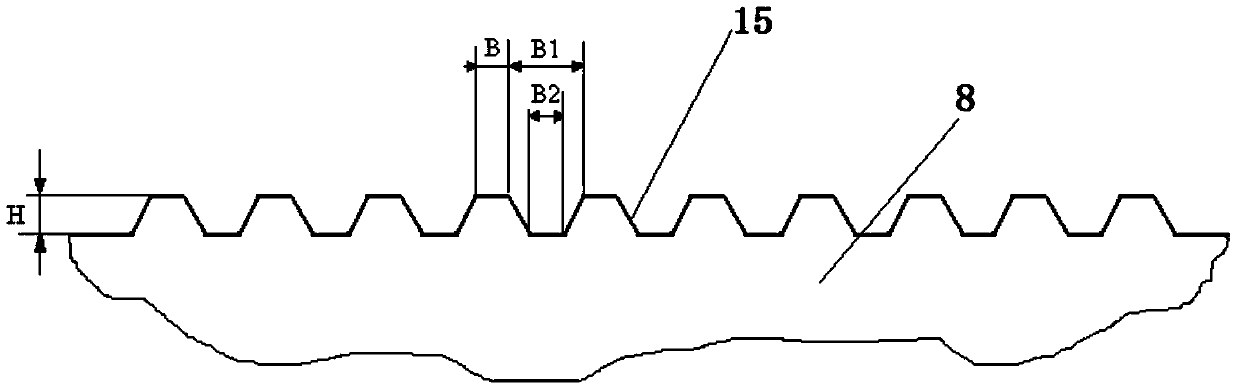

[0043] Such as Figure 1~4 The high-frequency welding and rolling multi-layer composite board production device shown includes a rolling mill 13, a first composite material roll guide roll 1, a second composite material roll guide roll 3, and a The base roll guide roller 2 between the roll guide rollers 3, the first conductive roller 6 that is arranged behind the first composite material roll guide roller 1 and can be in contact with the composite surface of the corresponding first composite sheet material 5, is arranged at the second The second conductive roller 8 behind the two composite material roll guide rollers 3 and capable of contacting the composite surface of the corresponding second composite material sheet 7 is arranged behind the base material roll guide roller 2 and can be connected to the corresponding base material sheet 9. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com