Dual-bonding wire head lead bonding device

A technology of wire bonding and wire lead, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problem that the bonding efficiency of wire bonding machines is difficult to be greatly improved, and achieve the effect of improving cost performance and wire bonding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

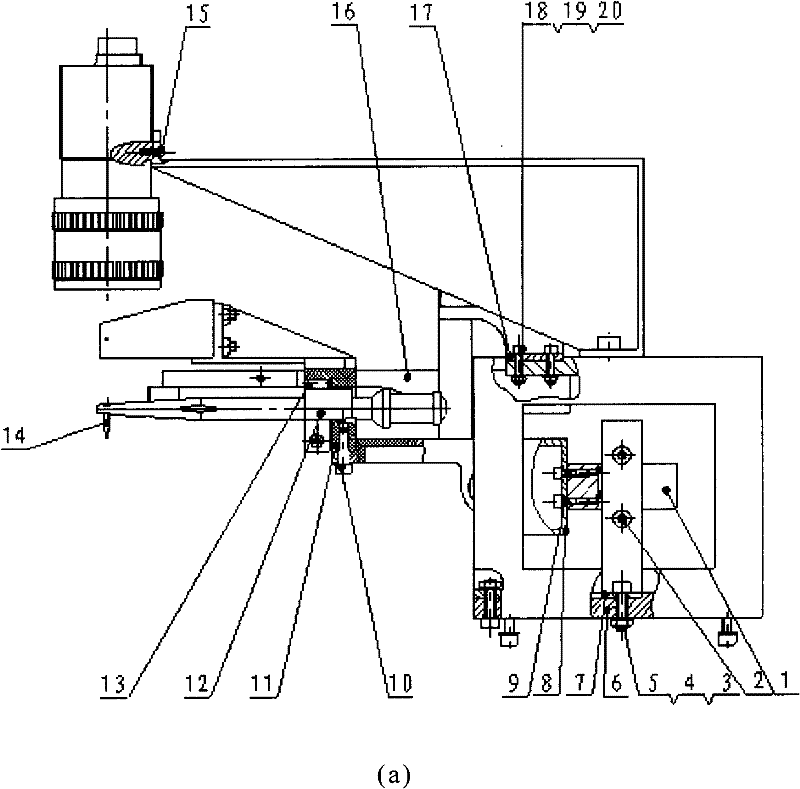

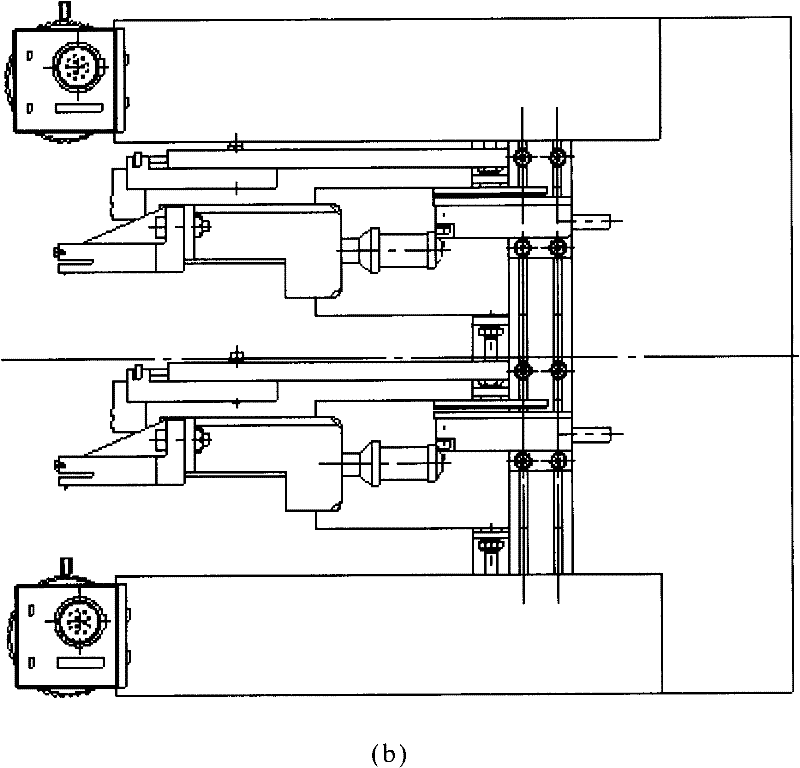

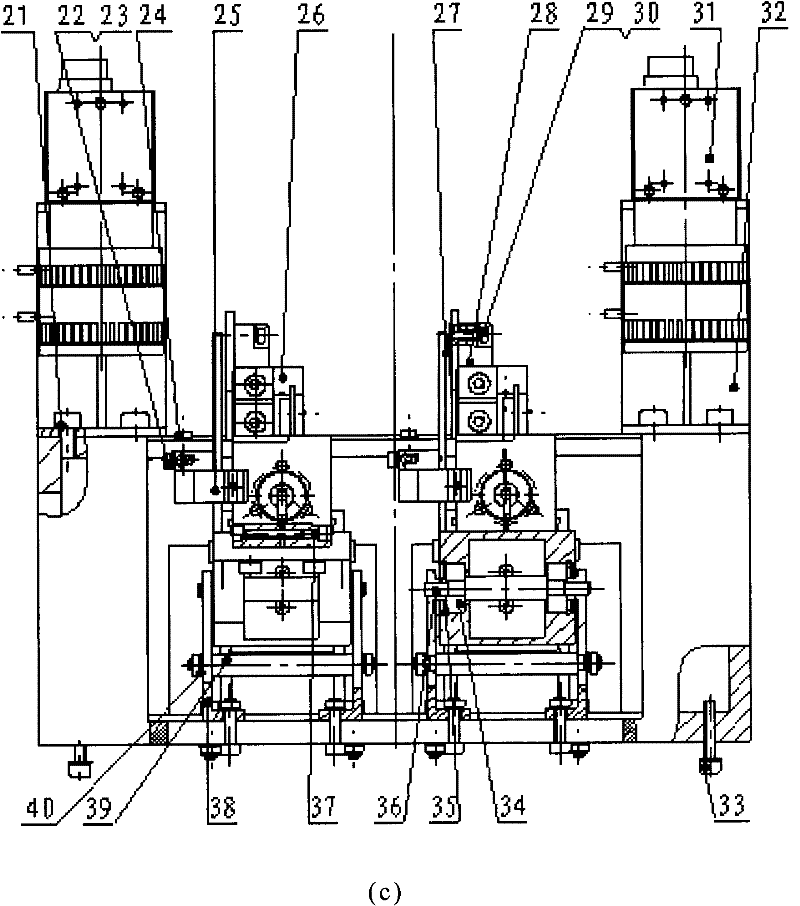

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0014] see figure 1 , the present invention includes two sets of identical welding wire heads, each welding wire head includes a wire clamp 26, a lighter support 16, a horn 12, a splitting knife 14, a horn clamping seat 11, and a horn support 8. The welding head rotating shaft 36, the rotating shaft support bearing 34, the shaft support frame 38, the motor support 7, the linear motor 1, the linear encoder 28, and the vision system 31. Each welding wire head is fixed on the support frame 6 by connecting bolts 5, and the support is fixed on the planar motion platform by bolts 33. Each welding wire head can rotate around the rotating shaft 36 under the up and down driving of the linear motor 1, and is combined with the wire clamp driving wire feeding system 26, the electronic ignition system 16, the horizontal XY direction plane movement system, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com