Electric power construction method

A technology of electric power construction and construction method, applied in the direction of overhead line/cable equipment, etc., can solve the problems of construction operation error and low accuracy of electric construction operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method of electric power construction, comprising the following construction steps:

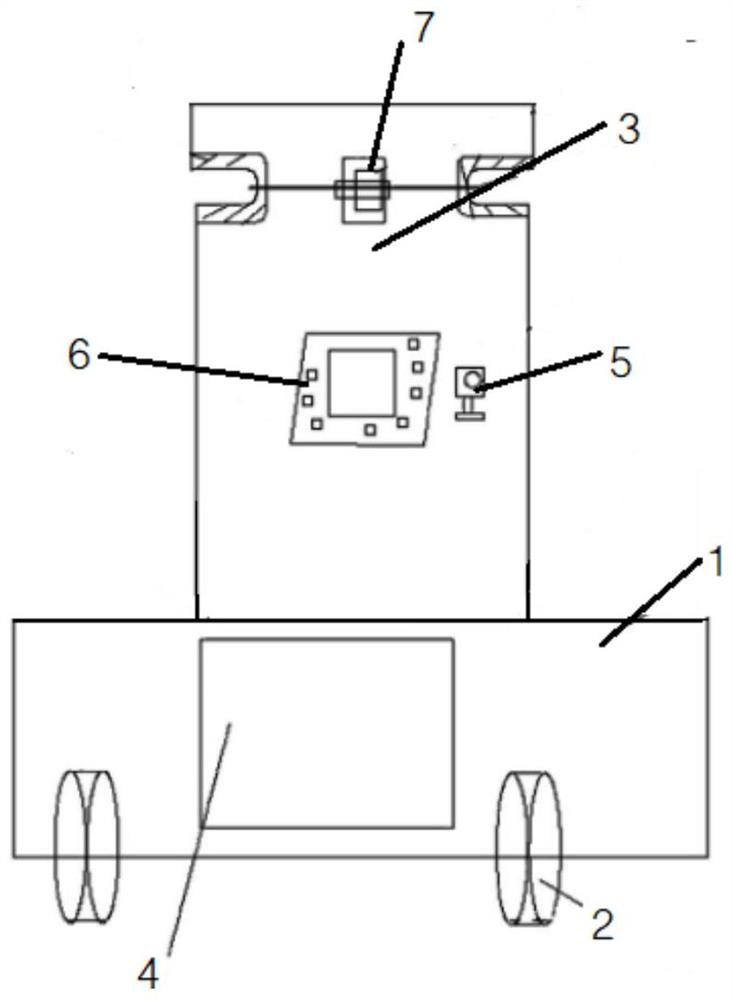

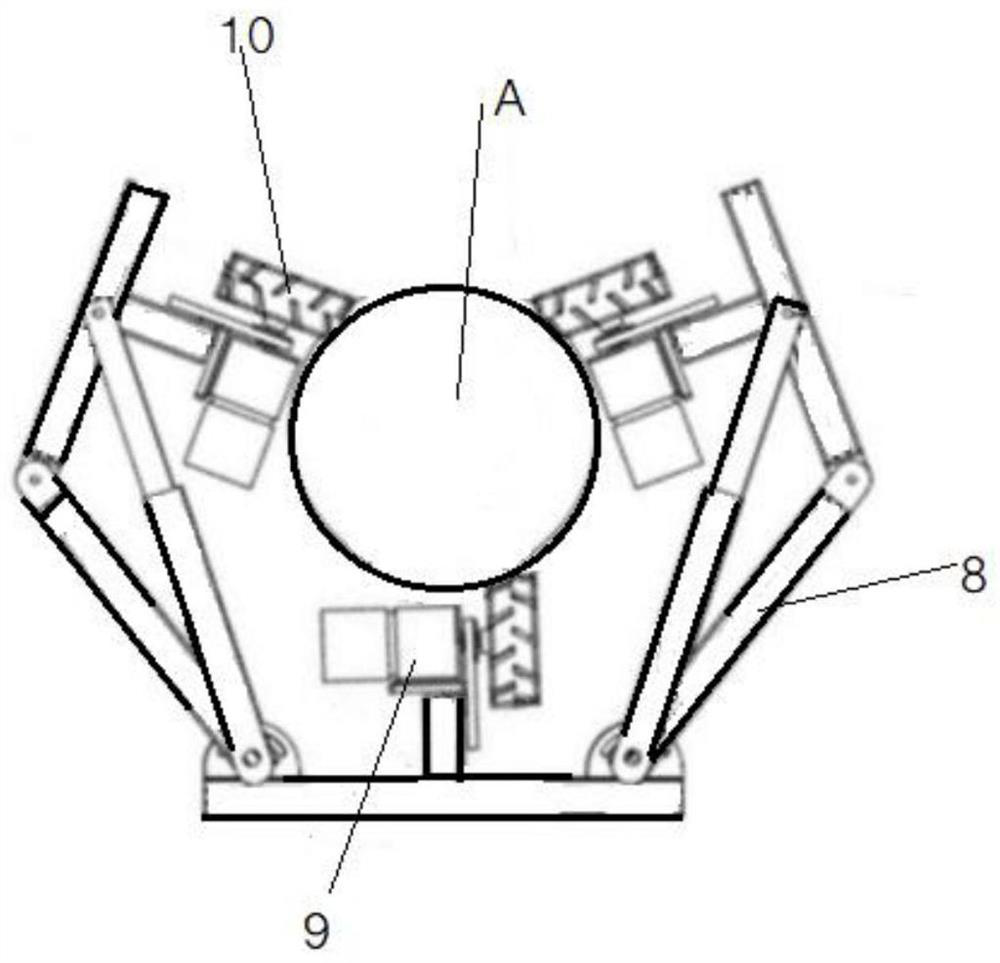

[0031] (1) Transport the drum-type cable frame that is bundled with high-voltage power lines to the middle position of two adjacent high-voltage power towers with a special-purpose transport vehicle, and utilize the lead-out equipment and the special-purpose transport vehicle to implement the wire-taking operation in two directions simultaneously;

[0032] (2) Real-time planning and adjustment of the moving path of the lead-drawing equipment during the movement process;

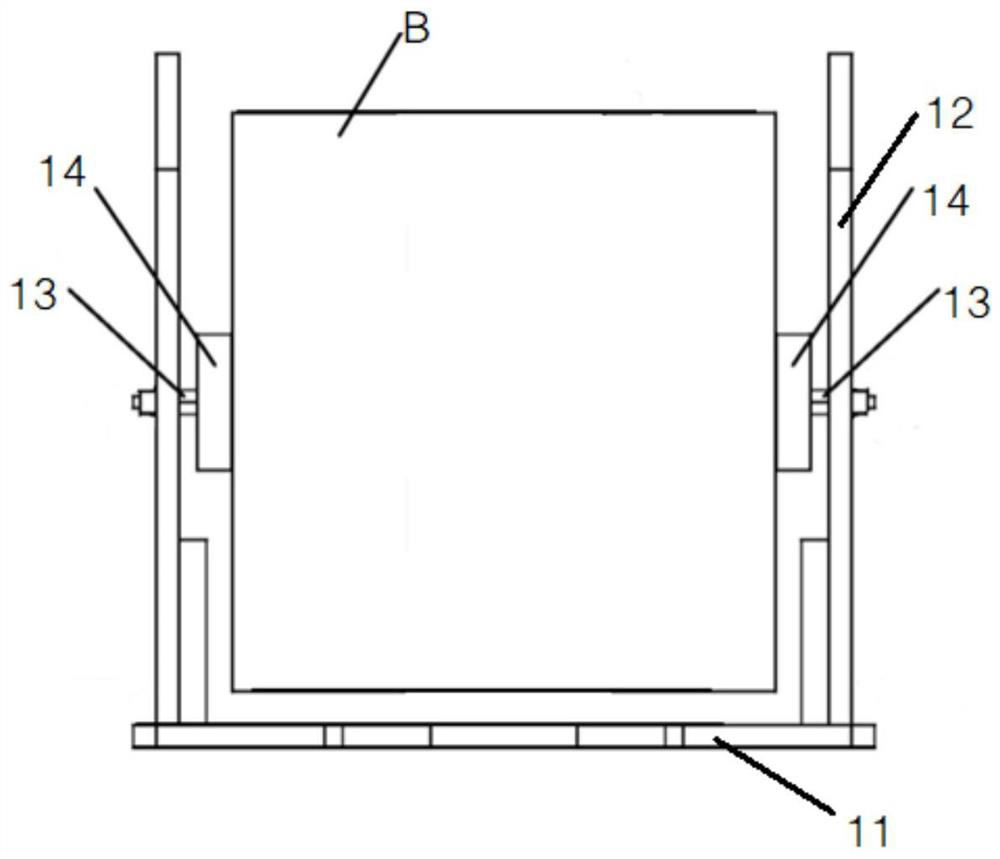

[0033] (3) The lead-out device reaches the position of the high-voltage power tower on one side, and the lead-out device is connected to the climbing cable previously set on the high-voltage power tower. The designated location of the power line;

[0034] (4) The special transport vehicle arrives at the position of the high-voltage power tower on the other side, cuts off the extracted high-voltage power line that m...

Embodiment 2

[0043] A method of electric power construction, comprising the following construction steps:

[0044] (1) Transport the drum-type cable frame that is bundled with high-voltage power lines to the middle position of two adjacent high-voltage power towers with a special-purpose transport vehicle, and utilize the lead-out equipment and the special-purpose transport vehicle to implement the wire-taking operation in two directions simultaneously;

[0045] (2) Real-time planning and adjustment of the moving path of the lead-drawing equipment during the movement process;

[0046] (3) The lead-out device reaches the position of the high-voltage power tower on one side, and the lead-out device is connected to the climbing cable previously set on the high-voltage power tower. The designated position of the power line; the climbing cable can be any form of cable, steel wire rope or ordinary rope in the field, as long as it can meet the requirements for the drawing line equipment to climb ...

Embodiment 3

[0064] A method of electric power construction, comprising the following construction steps:

[0065] (1) Transport the drum-type cable frame that is bundled with high-voltage power lines to the middle position of two adjacent high-voltage power towers with a special-purpose transport vehicle, and utilize the lead-out equipment and the special-purpose transport vehicle to implement the wire-taking operation in two directions simultaneously;

[0066] (2) Real-time planning and adjustment of the moving path of the lead-drawing equipment during the movement process;

[0067] (3) The lead-out device reaches the position of the high-voltage power tower on one side, and the lead-out device is connected to the climbing cable previously set on the high-voltage power tower. The designated location of the power line;

[0068] (4) The special transport vehicle arrives at the position of the high-voltage power tower on the other side, cuts off the extracted high-voltage power line that m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com