Lug

A technology of lugs and wires, applied in the direction of connection, connection insulation, conductive connection, etc., can solve the problems of slow speed, large power consumption, and easy breakage of the connection, and achieve the effects of convenient use, energy saving, and improved wiring speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

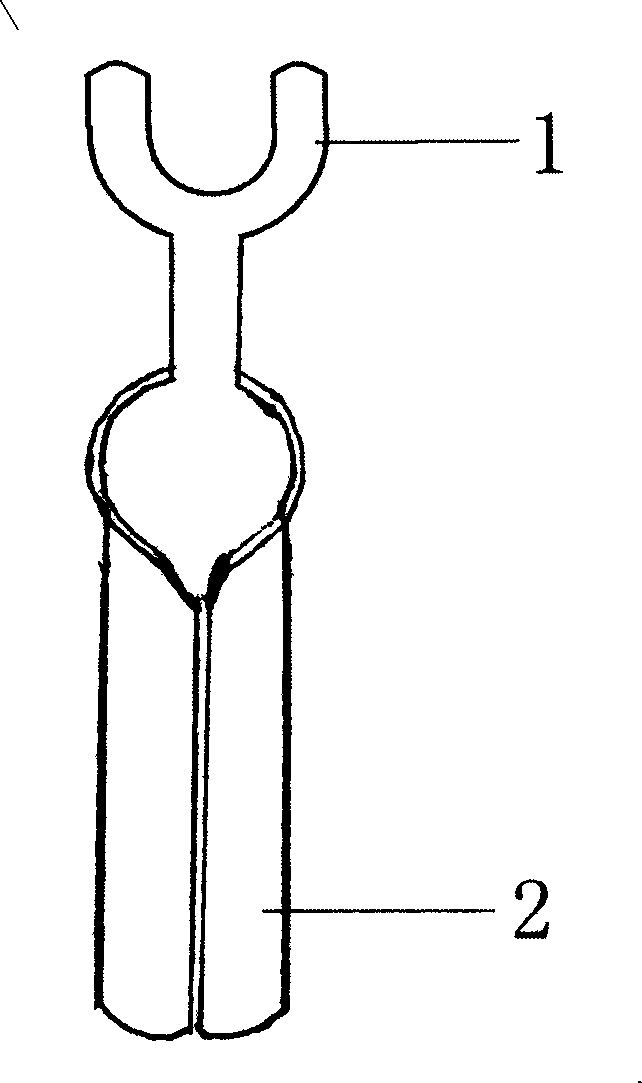

[0011] A lug, comprising a wiring tongue 1, a wire-pressing end 2, the wire-pressing end 2 is a circular metal tube, the size of which is just enough to press the wire wire, and it is characterized in that the direction of the wiring tongue of the wire-pressing end 2 has A V-shaped opening.

[0012] The wire crimping end 2 also has a plastic sleeve (not shown in the figure) covering the crimping wire.

[0013] When wiring, pass the wire through the bottom of the lug and clamp it at the V-shaped opening, the wire is stripped at the V-shaped opening, the wire wire is connected to the lug circuit, and the wire and the crimping end are used together with plastic Just put it on.

[0014] Although the above-mentioned embodiment has described the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com