Wiring machine platform and wiring method

A technology of wire bonding machine and wire bonding head, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, circuits, etc. It can solve the problems that the speed of wire bonding is difficult to be significantly improved, and the production line cannot be expanded, so as to achieve the effect of increasing the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

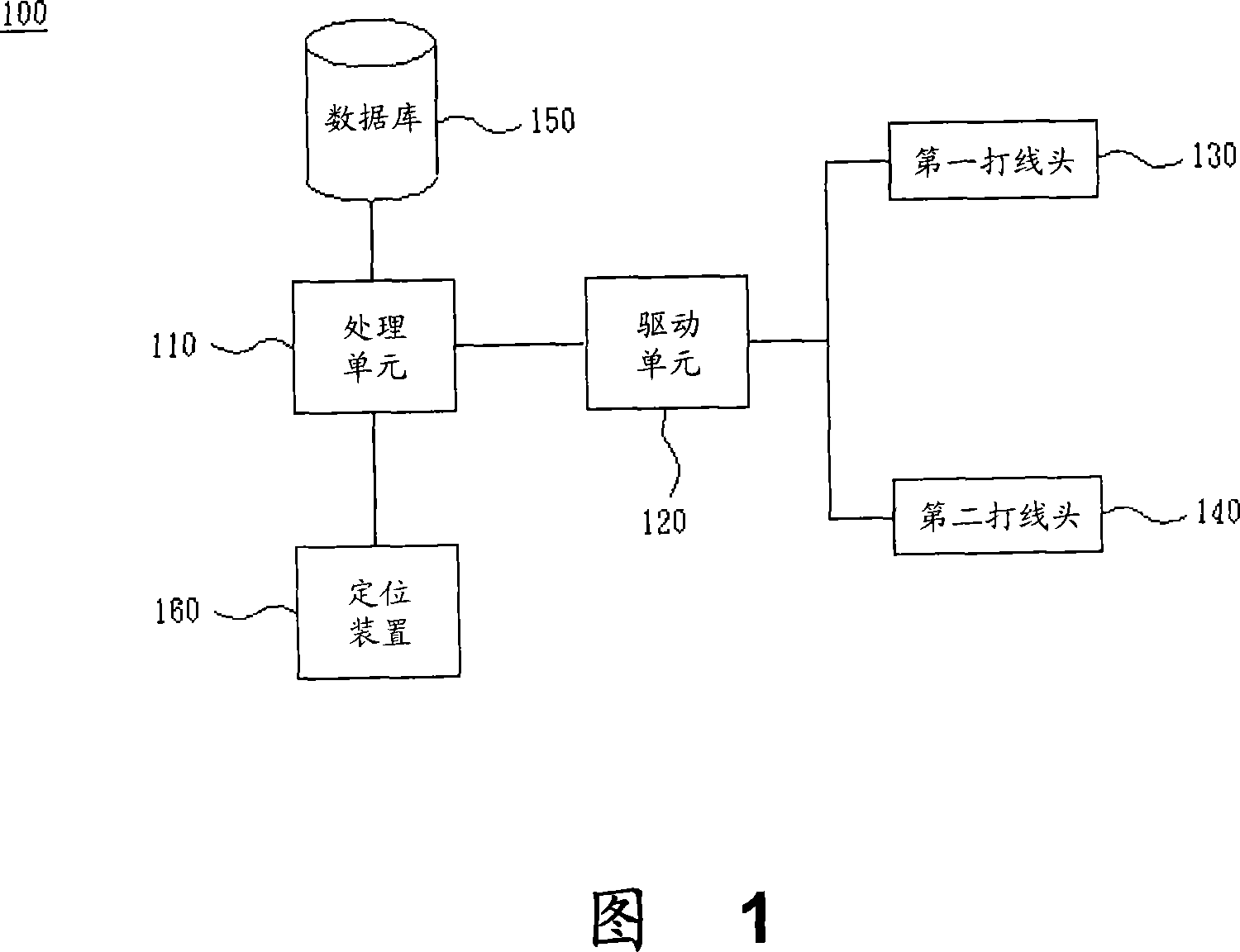

[0024] Please refer to FIG. 1 , which shows a functional block diagram of a wire bonding machine according to the present invention. The wire bonding machine 100 is used for simultaneously bonding at least one first chip and a second chip (not shown in the figure) on a substrate. The wire bonding machine 100 includes a first wire bonding head 130 and a second wire bonding head 140 , a driving unit 120 and a processing unit 110 . The driving unit 120 is used to move the first wire-bonding head 130 and the second wire-bonding head 140, such as a driving motor; the processing unit 110 is used to output control commands to the driving unit 120 to control the first wire-bonding head 130 and the second wire-bonding head 140 The moving mode and wire bonding action, the processing unit 110 is, for example, a microprocessor or an application specific integrated circuit (ASIC).

[0025] In addition, the wire bonding machine 100 further includes a database 150 for storing operation para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com