Yarn discharging mechanism of yarn double twister

A double-twisting machine and yarn technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc. It can solve the problems of slow moving speed, fast yarn winding speed, and the need to improve the reciprocating speed of the wire arrangement mechanism, etc. Problems, achieve the effect of increasing speed, increasing efficiency, and increasing the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

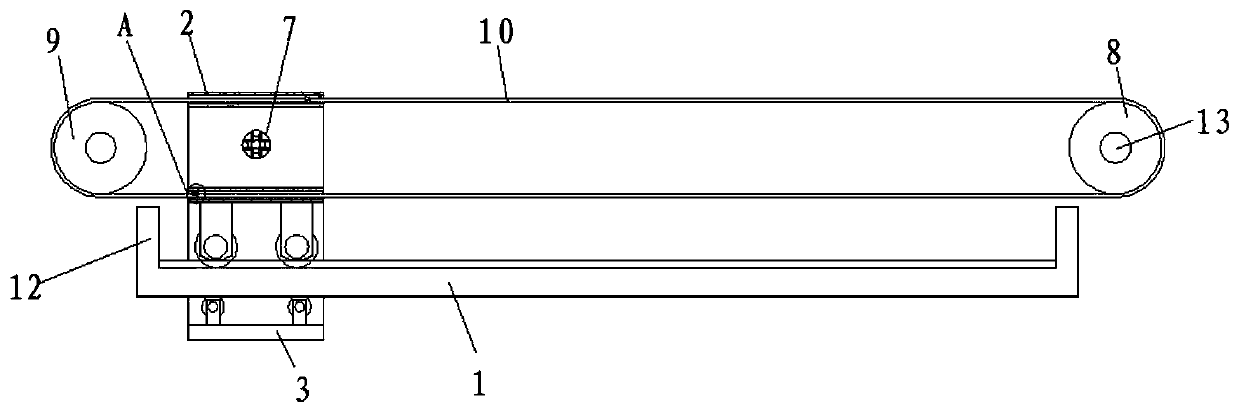

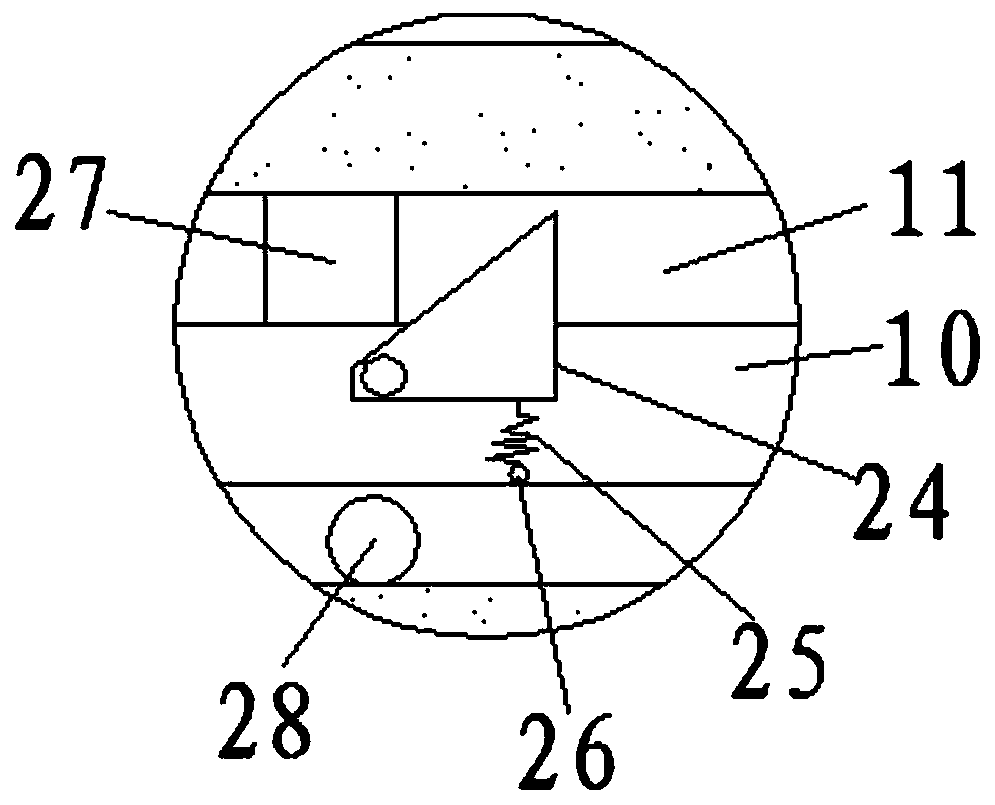

[0035] see Figure 1-6 According to an embodiment of the present invention, a yarn arranging mechanism for a double-twisting machine includes a base 1, on which a mobile terminal 2 is provided, and the mobile terminal 2 includes a mobile seat 3, and the inner wall of the mobile seat 3 passes through The upper roller 4 and the lower roller 5 are connected with the base 1, the number of the upper roller 4 is four, the number of the lower roller 5 is four, and the mobile seat 3 is fixed with a vertical plate 6, The middle part of the vertical plate 6 is provided with a rope hole 7, and the two ends of the base 1 are respectively provided with a driving wheel 8 and a driven wheel 9, and the driving wheel 8 and the driven wheel 9 are connected by a synchronous belt 10. connection, the moving seat 3 and the vertical plate 6 are provided with a synchronous belt through hole 11, the synchronous belt through hole 11 runs through the synchronous belt 10, and the synchronous belt 10 is f...

Embodiment 2

[0038] see Figure 1-8 , for the vertical plate 6, the two ends of the vertical plate 6 are fixedly connected with the upper end of the mobile base 3 through reinforcing ribs 18.

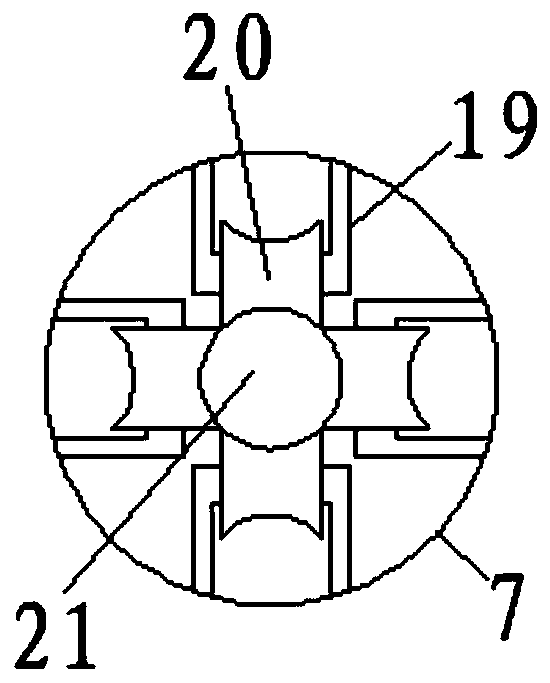

[0039] For the rope-through hole 7 , several sets of brackets 19 are uniformly fixed on the inner wall of the rope-through hole 7 , pulleys 20 are arranged between the brackets 19 , and rope-through gaps 21 are formed between the pulleys 20 .

[0040] For the base 1, two upper rails 22 and lower rails 23 are respectively provided on both sides of the base 1, the upper rail 22 is provided with the upper roller 4, and the lower rail 23 is provided with the Describe lower roller 5.

[0041] Through the above solution of the present invention, the friction force between the yarn and the rope hole 7 can be reduced by setting the pulley 20 , and the moving track of the mobile terminal 2 is restricted by setting the upper track 22 and the lower track 23 .

[0042] For the moving toggle mechanism, the mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com