Energy-saving emission-reducing type gasoline engine oil and preparation method thereof

A gasoline engine oil, energy-saving and emission-reducing technology, applied in the field of lubricating oil, can solve problems such as hindering practical application, and achieve the effect of avoiding cold start wear and reducing pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The percentage by weight of each component in the finished product of energy-saving and emission-reducing engine oil (required by API SN SAE 5W / 40 specification):

[0018] Base oil: 100N 20.998%, 150N50%, PAO-49%;

[0019] Viscosity index improver SCR-261: 9.0%;

[0020] Composite additive H9089: 9.0%;

[0021] Defoamer T901: 0.002%;

[0022] Nano-friction modifier TND001: It is composed of 1.5% nano-diamond friction modifier and 0.5% nano-boron ceramic friction modifier.

[0023] The preparation process includes the following steps:

[0024] Pump base oils: 100N, 150N, and PAO-4 into the blending tank in sequence, raise the temperature to 70±5°C, add viscosity index improver, composite additive H9089, defoamer T901, and nano-friction modifier in sequence, and stir well and evenly. 400-500 mesh filtration and cooling to obtain the finished product.

Embodiment 2

[0026] The percentage by weight of each component in the finished product of energy-saving and emission-reducing engine oil (required by API SN SAE 5W / 40 specification):

[0027] Base oil: 100N 22.995%, 150N47%, PAO-410%;

[0028] Viscosity index improver SCR-261: 9.0%;

[0029] Composite additive H9089: 9.0%;

[0030] Defoamer T901: 0.005%;

[0031] Nano-friction modifier TND001: composed of 1.0% nano-diamond friction modifier and 1.0% nano-boron ceramic friction modifier.

[0032] The preparation process is the same as in Example 1.

Embodiment 3

[0034] The percentage by weight of each component in the finished product of energy-saving and emission-reducing engine oil (required by API SN SAE 5W / 40 specification):

[0035] Base oil: 100N 20%, 150N 48.5%, PAO-411.5%;

[0036] Viscosity index improver SCR-261: 9.0%;

[0037] Composite additive H9089: 8.995%;

[0038] Defoamer T901: 0.005%;

[0039] Nano-friction modifier TND001: composed of nano-diamond friction modifier 1.0%, nano-Ti 3 (BO3) 2 0.2% and 0.8% calcium cetyl borate.

[0040] The preparation process is the same as in Example 1.

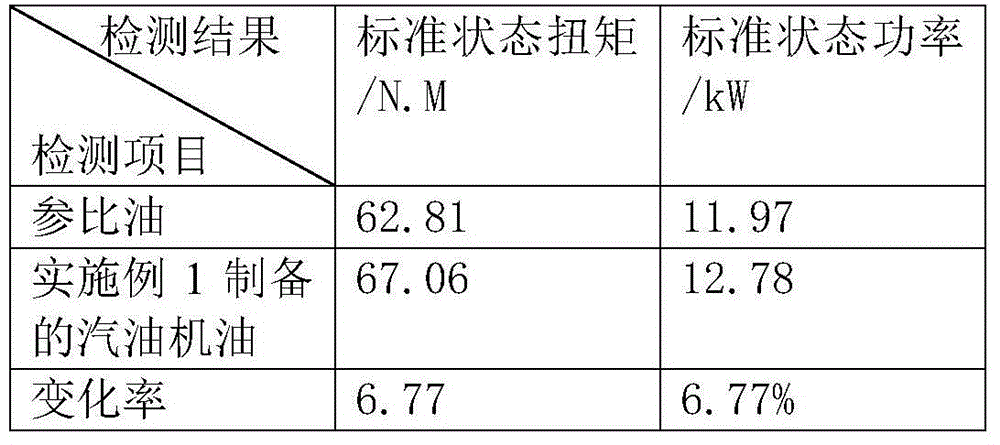

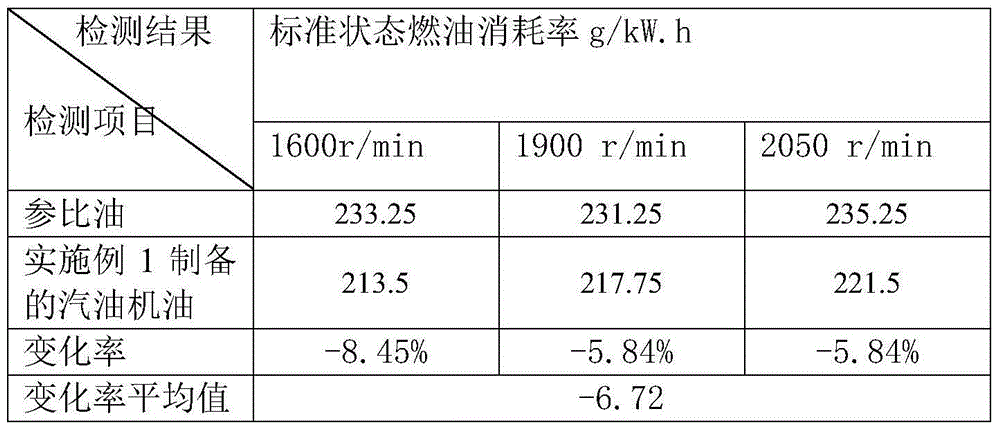

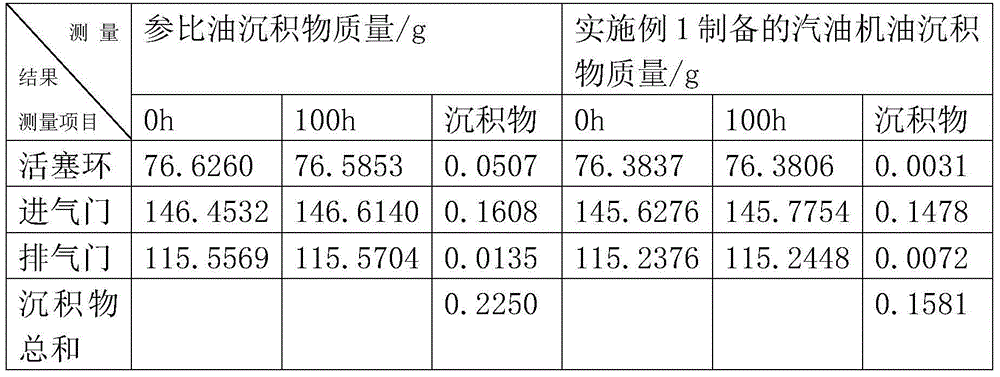

[0041] Effect experiment 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com