Warm-hot forming method for boron-free medium-manganese steel

A warm forming, manganese steel technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of restricting the lightweight and safety of automobiles, low elongation, etc., to improve the lightweight and safety, high The effect of elongation, high plastic mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

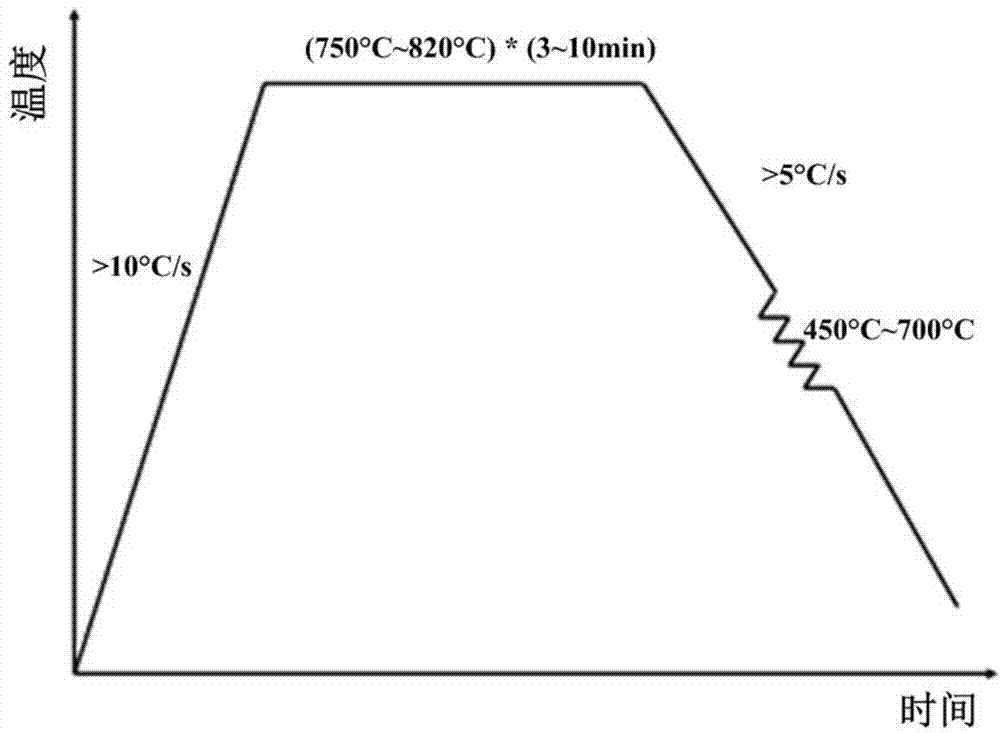

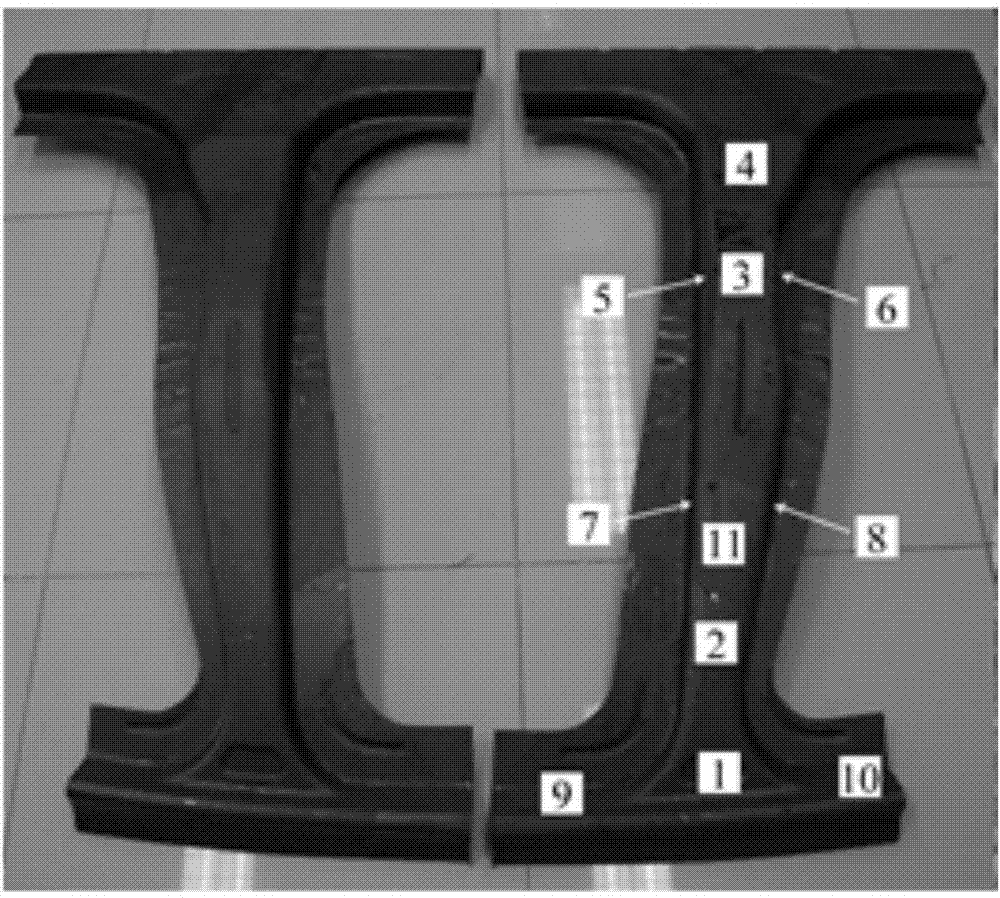

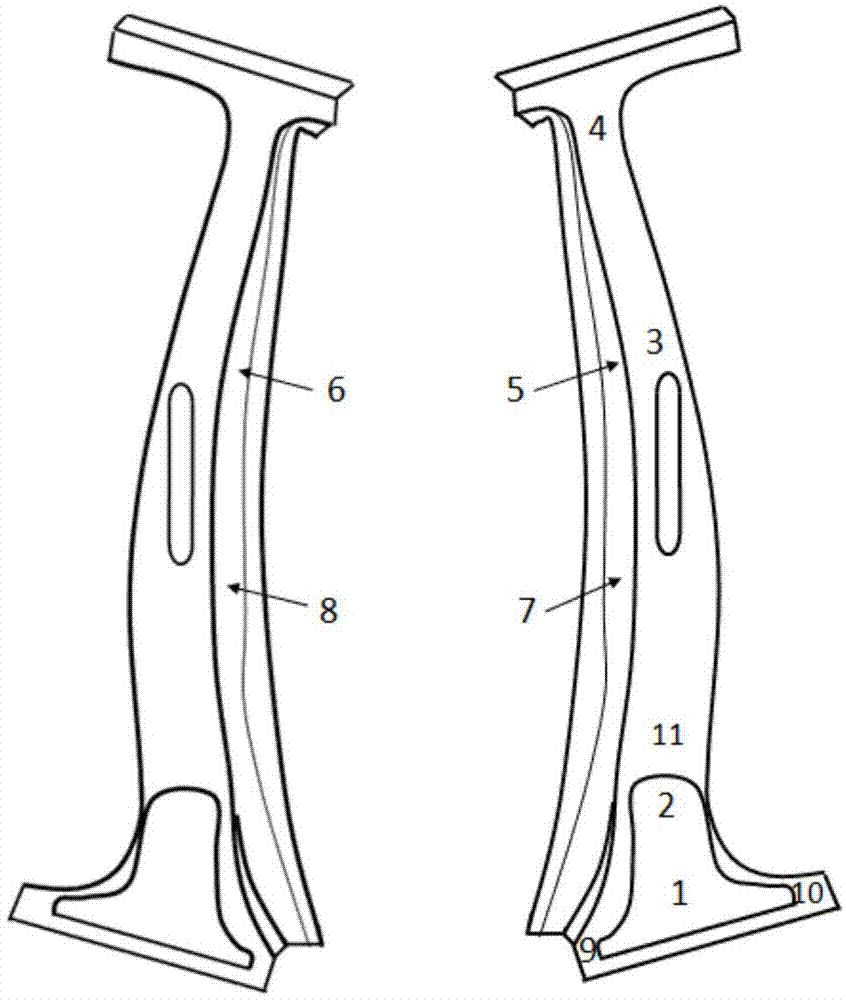

[0033] The boron-free medium-manganese steel sheet (the weight percent of its chemical composition is: C: 0.1%; Mn: 5%; P: 0.015%; S: 0.015%; N: 0.005%; the balance is Fe and unavoidable impurities) Raise the temperature to 800°C, keep it warm for 3 minutes, transfer it to the stamping die, the stamping temperature is 500°C, quench it at a cooling rate of 10°C / s, and hold the pressure for 10s. Using the above process parameters to make the B-pillar of the automobile, such as figure 2 , image 3 , and select 11 representative points from above (such as the edge of the side wall of the B-pillar structural member or the upper plane of the structural member or the edges of the two ends of the structural member, etc.), and measure the relevant mechanical properties As in Table 1.

[0034] Each mechanical performance parameter value at the corresponding point of the present invention in table 1

[0035]

[0036] It can be seen from the measured mechanical properties that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com