Method and device for industrial furnace atmosphere automatic combustion control

An industrial furnace and atmosphere technology, which is applied in the direction of furnace control devices, furnaces, furnace components, etc., can solve the problems that the combustion atmosphere control technology cannot meet, and the real-time automatic control of the combustion atmosphere cannot be realized, so as to improve fuel combustion efficiency and increase furnace temperature. , the effect of reducing exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

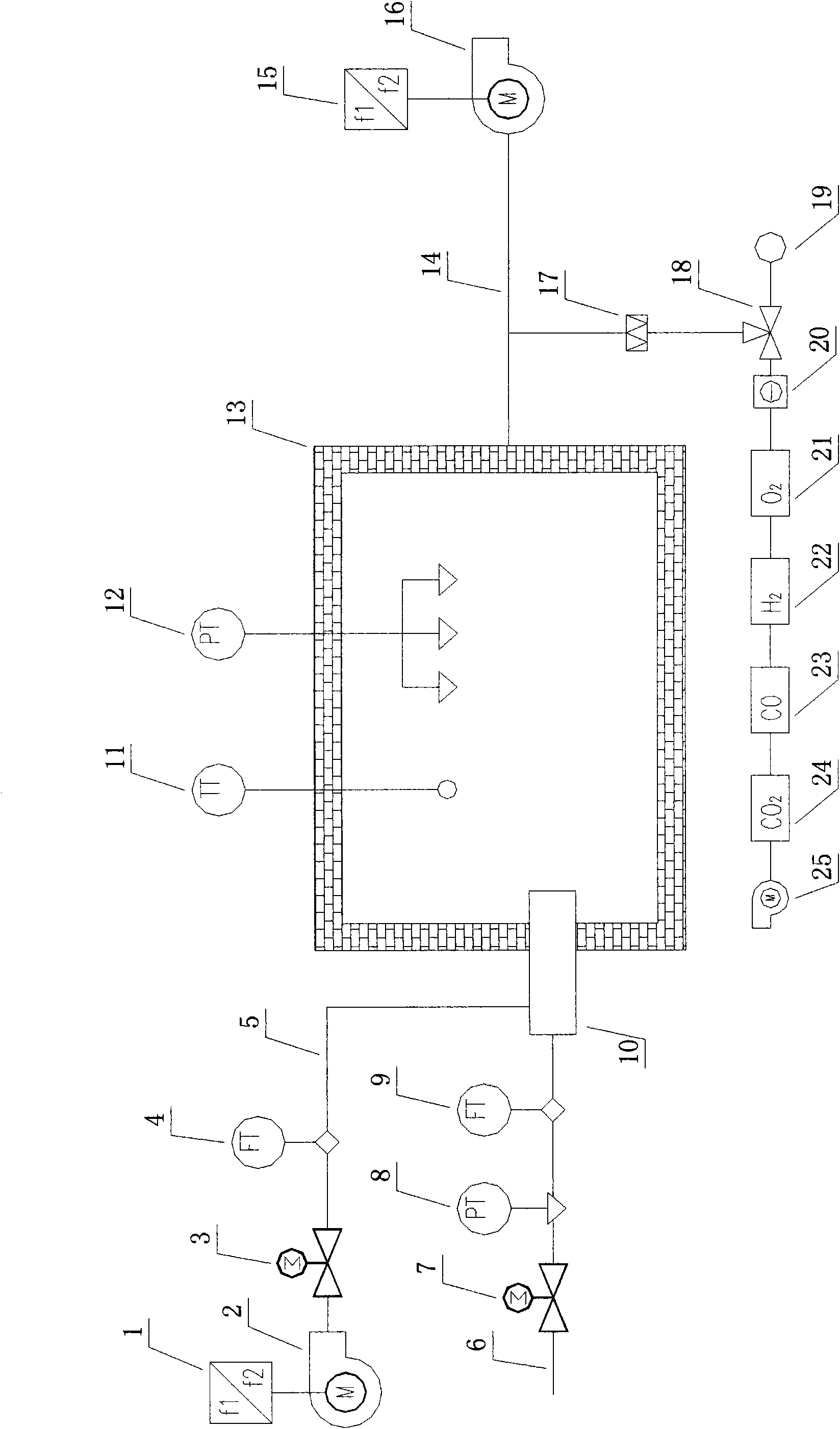

[0030] Such as figure 1 As shown, it is a mixed combustion mode industrial furnace commonly used in the industry at present. The present invention installs a sampling probe at the flue gas outlet 14 of the industrial furnace, and performs coarse filtration 17, and uses a gas sampling pump 25 to continuously extract the flue gas, and its flue gas sampling The flow rate is controlled within the range of 3-5L / min, and a filter water removal and impurity removal device 20, a timing backflushing and timing verification valve 18, and a verification backflushing gas source 19 are installed on the flue gas sampling pipe. Pass the flue gas through three gas chambers in turn, and test the O in the flue gas respectively. 2 , H 2 , CO content, and finally connected to an infrared gas analyzer to detect CO in the flue gas 2 content, and then calculated according to the characteristics of the fuel, the characteristics of the industrial furnace and the production process, with H 2 , the C...

Embodiment 2

[0036] An automatic control device for industrial furnace atmosphere combustion, its control structure is as attached figure 1 Shown, comprise industrial furnace furnace body 13, be provided with induced draft fan 16 in the flue 14 of described industrial furnace furnace body 13, described induced draft fan 16 is controlled by induced air flow controller 15, be provided with in industrial furnace furnace body 13 A burner 10, a temperature detector 11, a three-point pressure detector 12 and a smoke filter 17. The burner 10 is connected to a combustion control mechanism, and the smoke filter 17 is connected to a smoke detection mechanism.

[0037] The combustion control mechanism includes a fuel pipeline 6 and a combustion-supporting air pipeline 5 connected in parallel. The combustion-supporting air pipeline 5 is connected in series with a combustion-supporting air blower 2, a combustion-supporting air regulating valve 3 and a combustion-supporting air flow detector 4. The combu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com