Engine compression release method and apparatus

a technology of engine compression and release method, which is applied in the direction of machines/engines, valve arrangements, output power, etc., can solve the problems of large and more expensive batteries and motors than are required for less frequent use, and place unacceptably high stresses on valve gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

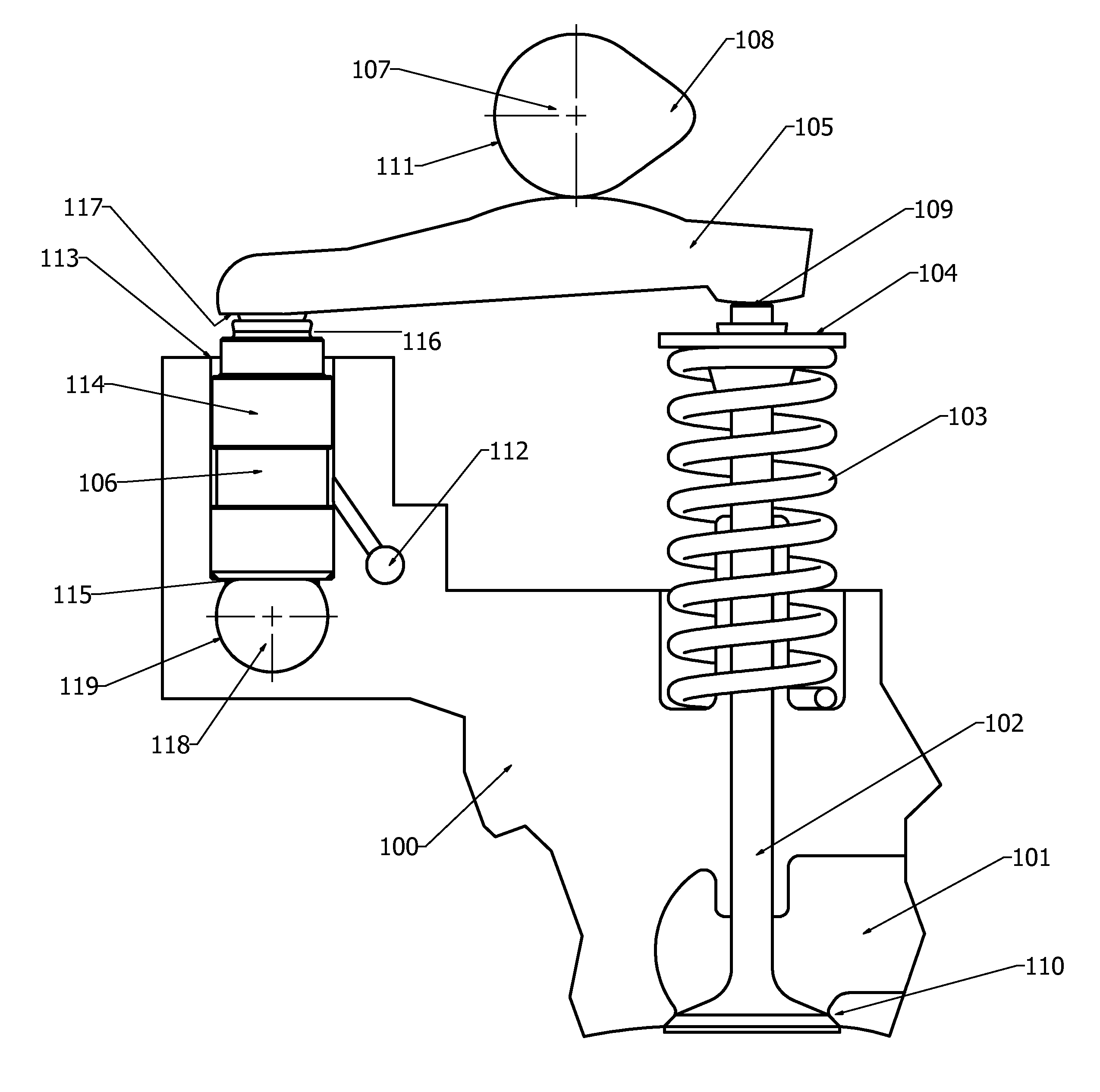

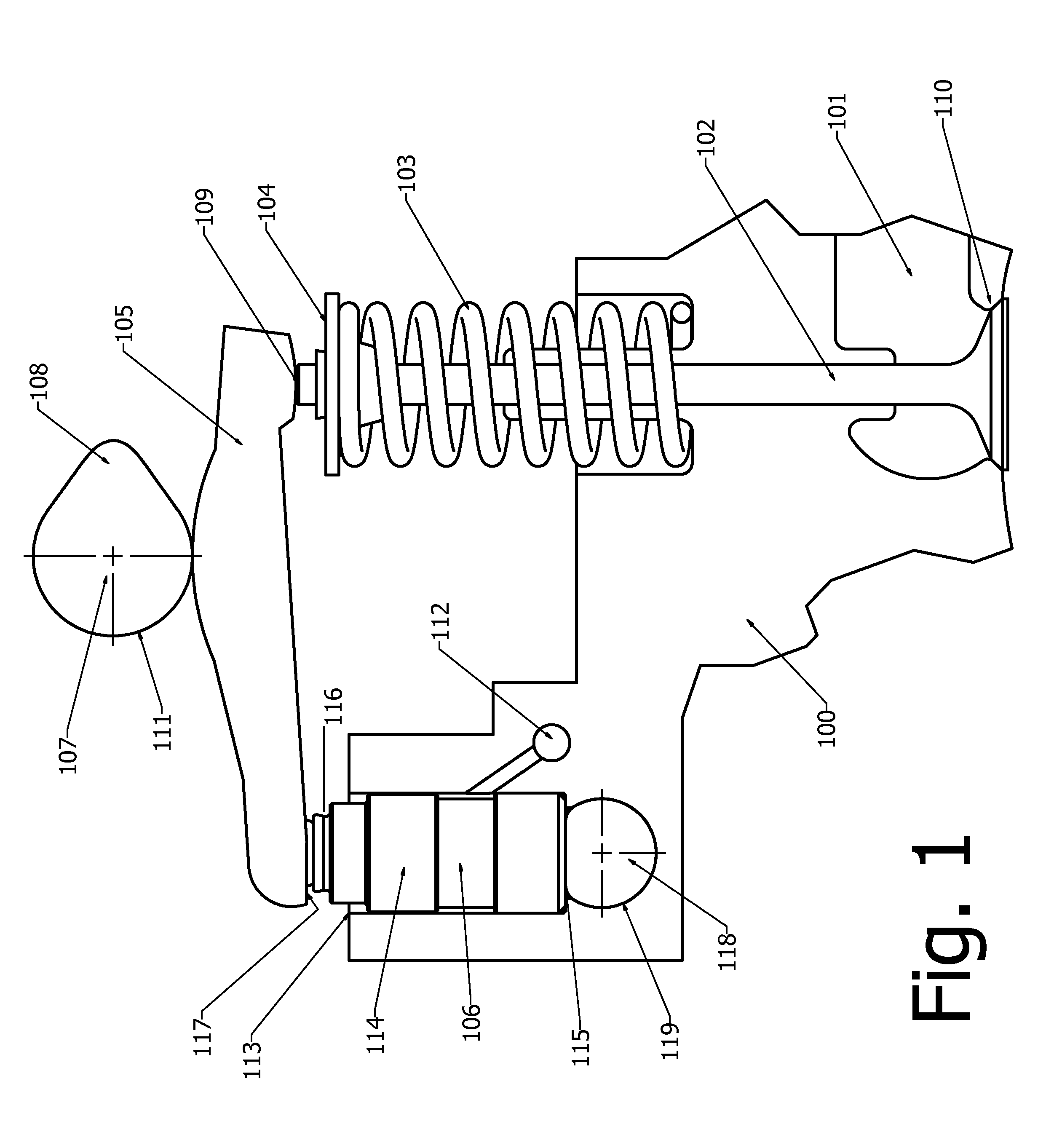

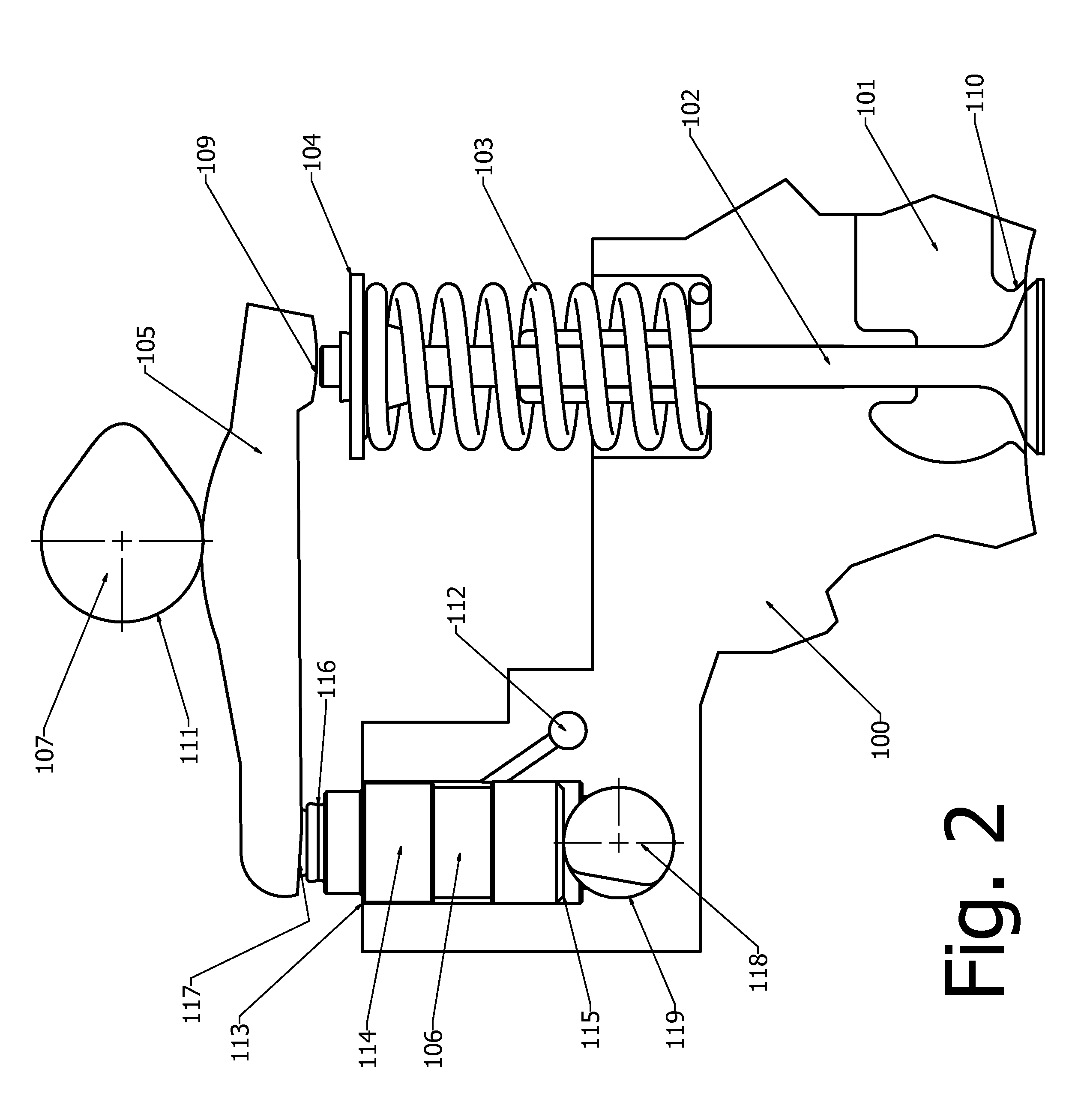

[0018]The cam operated compression release mechanism according to the present invention is illustrated in FIG. 1 and FIG. 2. The cylinder head 100 incorporates a gas flow port 101 with a poppet valve 102 that serves to open and allow gas flow in or out of the cylinder volume or close to confine the gas in the cylinder during the compression and expansion strokes. The poppet valve is biased in the closed position by a spring 103 acting through the spring retainer 104. A rocker arm 105 pivoted on a lash adjuster 106 engages a rotating cam 107 with a lobe 108 work together to periodically open the poppet valve by pressing on valve stem tip 109. The spring 103 is compressed as the valve opens, and then expands to close the valve. In the normal operating mode shown in FIG. 1 the valve closes fully and seals against the valve seat 110 when the cam base circle 111 is in contact with the rocker arm 105, thereby preventing gas flow in or out of the cylinder. The lash adjuster 106 is an oil-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com