Low-emission combustion chamber with double-layer axial hydrocyclone adopted at precombustion stage

A technology of pre-combustion stage and combustion chamber, which is applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of reinforcement, difficulty in balancing combustion efficiency and low emission, and poor fuel atomization, so as to reduce pollution emissions and effectively It is beneficial to control the temperature of the combustion zone and improve the combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

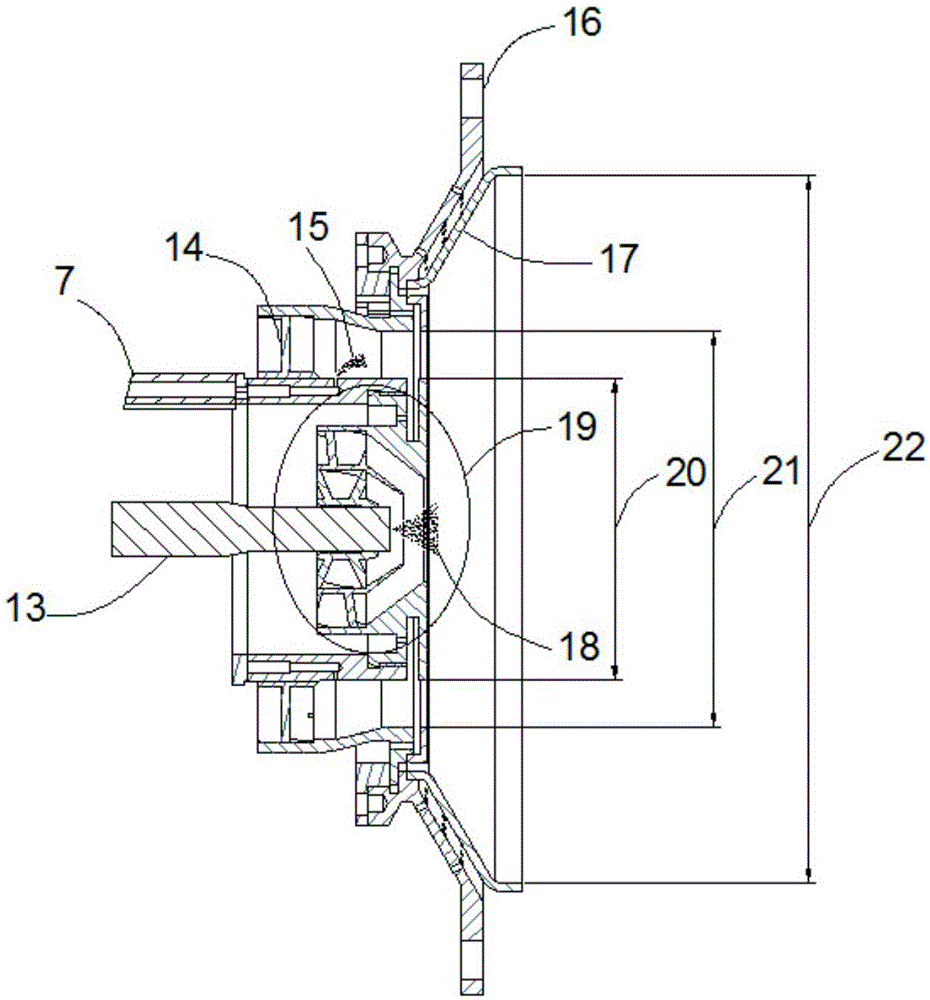

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

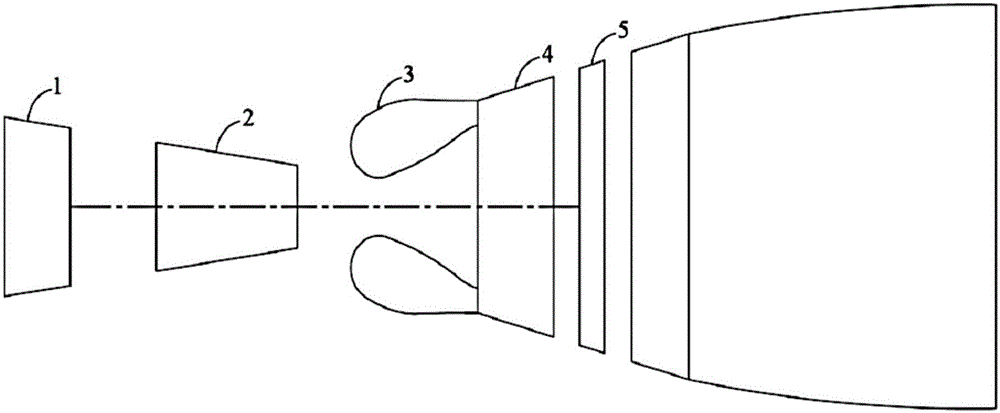

[0026] figure 1 It is a schematic diagram of the engine structure, including a low-pressure compressor 1, a high-pressure compressor 2, a combustion chamber 3, a high-pressure turbine 4 and a low-pressure turbine 5. When the engine is working, the air is compressed by the low-pressure compressor 1 and the high-pressure compressor 2 and then enters the combustion chamber 3. Fuel is injected and combusted to form high-temperature and high-pressure gas, which impacts the high-pressure turbine 4 and the low-pressure turbine 5, thereby driving the low-pressure compressor. 1 and high-pressure compressor 2 work, and output power.

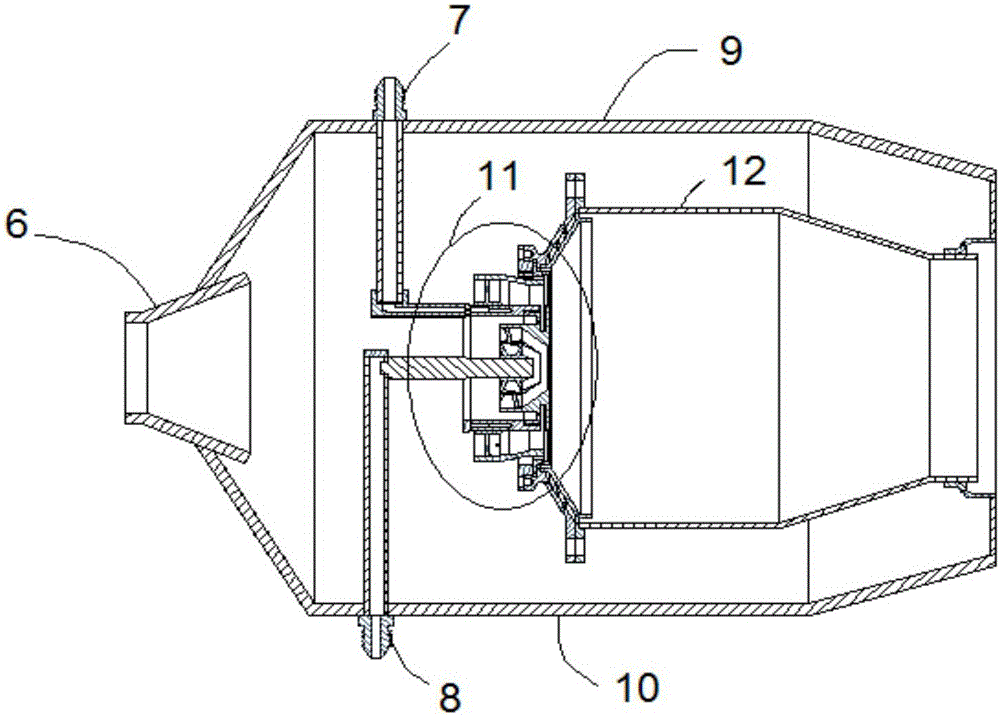

[0027] Such as figure 2As shown, a single-ring cavity structure is adopted, and the main structure includes a diffuser 6, a casing 9 outside the combustion chamber, a casing 10 inside the combustion chamber, a flame tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com