Engine exhaust gas recirculation (EGR) valve closed-loop control system

An EGR valve and closed-loop control technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve problems such as reducing gasoline combustion performance, affecting vehicle performance, and reducing aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

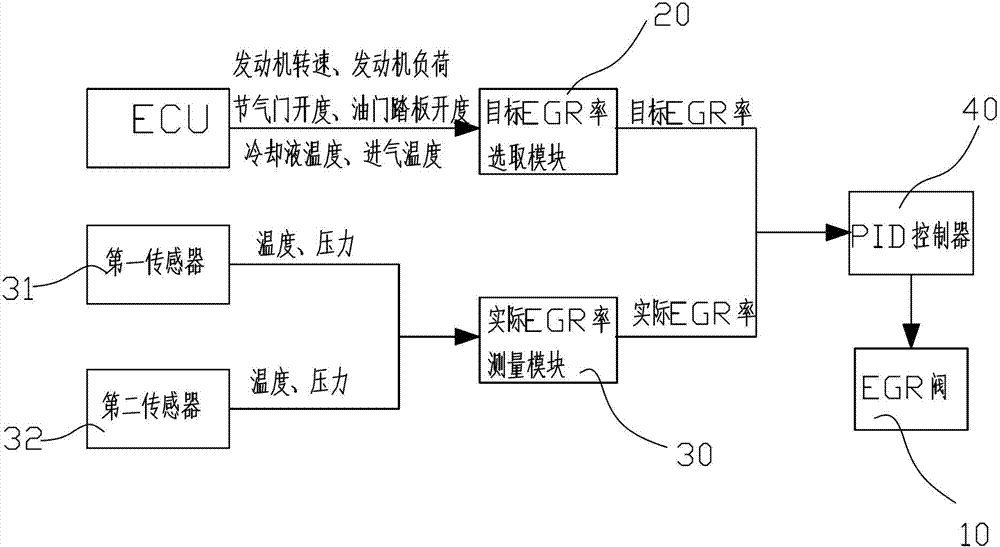

[0013] Such as figure 1 , an engine EGR valve closed-loop control system, comprising an EGR valve 10, a target EGR rate selection module 20, an actual EGR rate measurement module 30 and a PID controller 40;

[0014] The target EGR rate selection module 20 and the actual EGR rate measurement module 30 are respectively connected to two input ends of the PID controller 40;

[0015] The target EGR rate selection module 20 stores the target EGR rate under different working conditions; the actual EGR rate measurement module 30 measures the actual EGR rate of the EGR valve under the current working condition; the main function of the target EGR rate is to provide the current The value of the ideal EGR rate of the vehicle under working conditions is sent to the PID controller as a basis for comparison. When the actual EGR rate of the vehicle is consistent with the ideal EGR rate, the vehicle works in the best state. Among them, PID (proportional-integral-derivative) control is a clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com