Multi-head efficient pre-mixing type combustion system of ground flare

A ground torch and combustion system technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of unsatisfactory premixing effect and affecting combustion effect, and achieve the purpose of making up for the lack of primary air, reliable flame stabilization and flame transfer, The effect of increasing the secondary contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

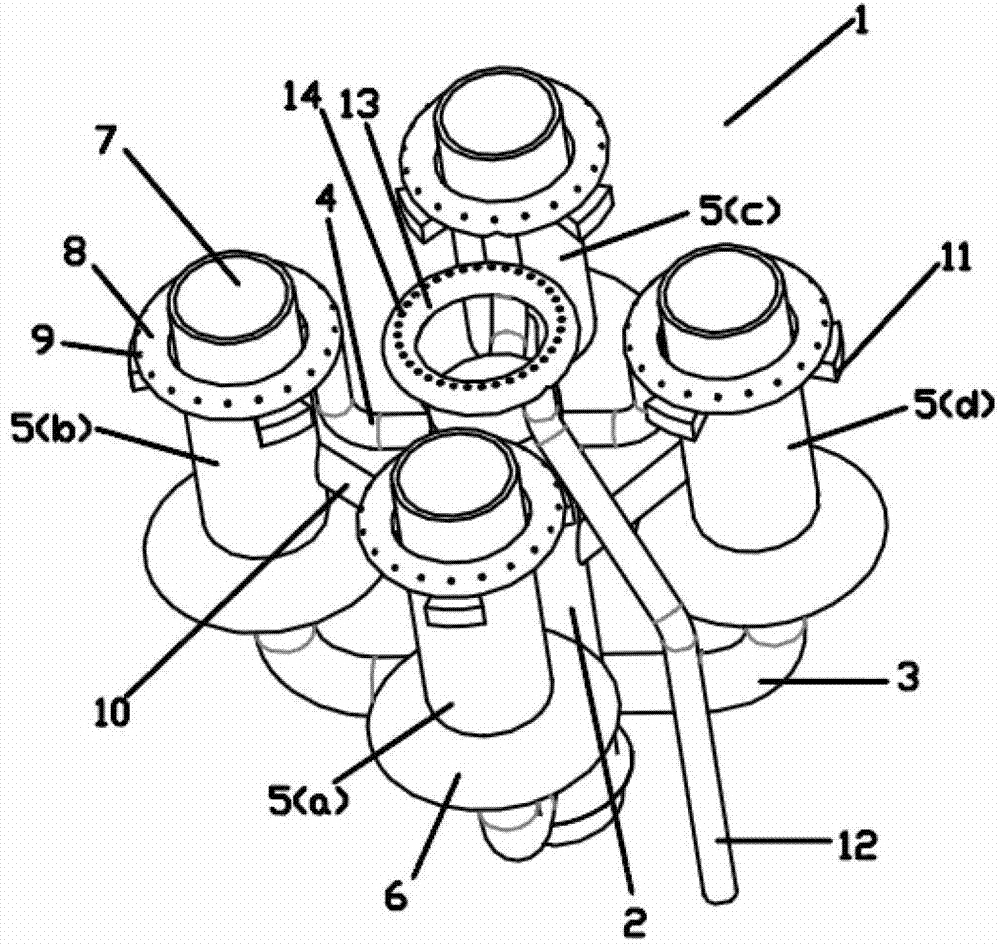

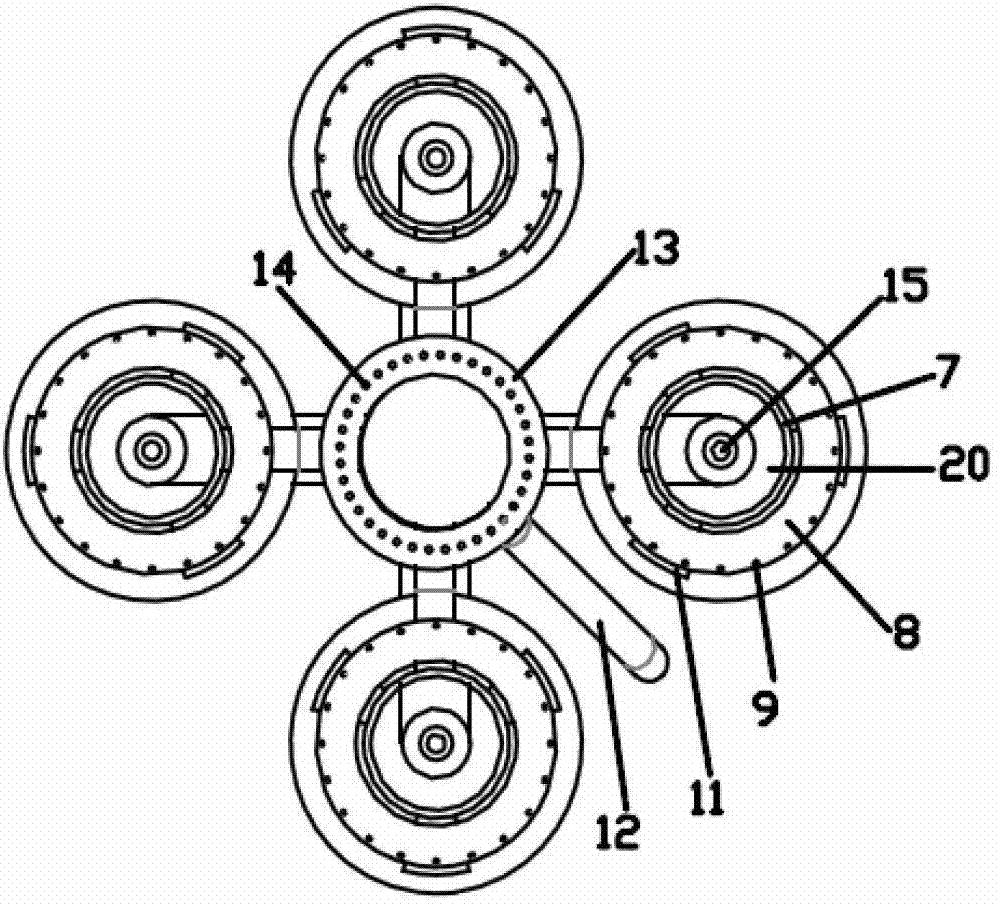

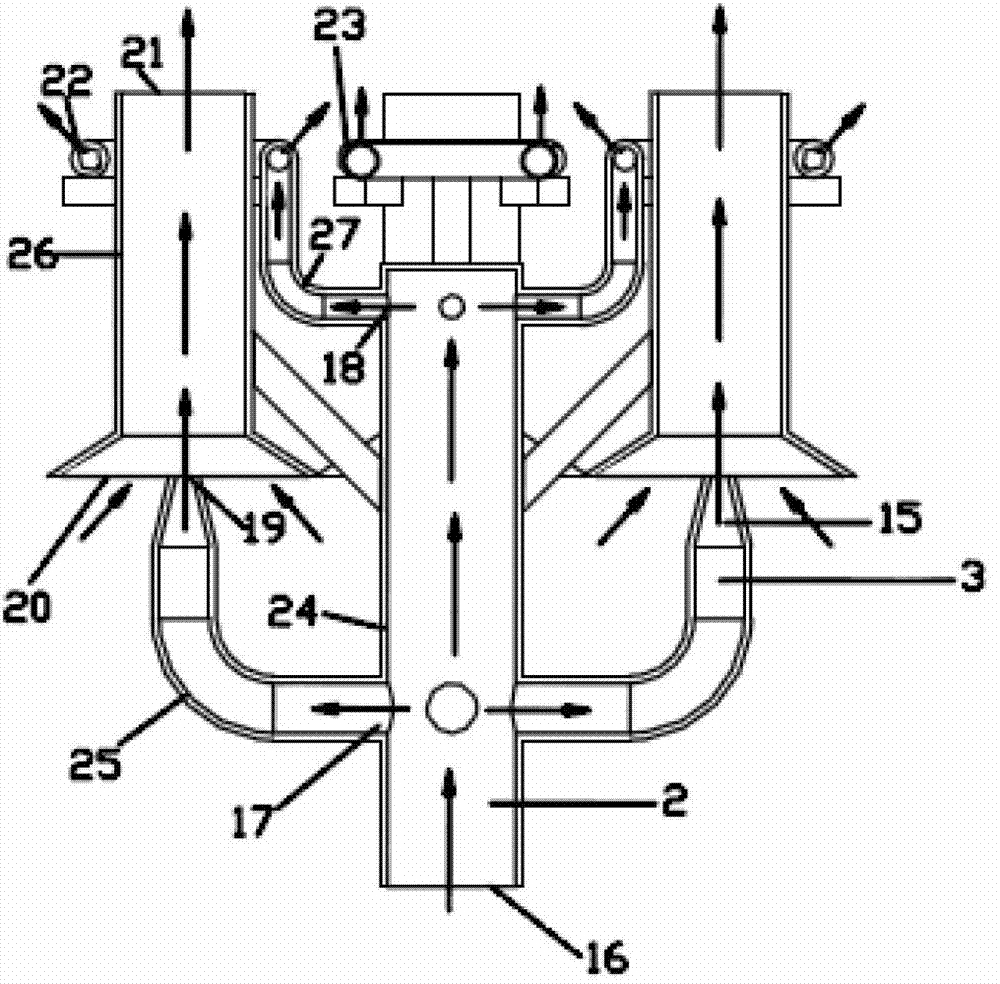

[0043] Such as Figure 1-3 , as shown in 8-11.

[0044] A multi-head high-efficiency premixed combustion system for ground torch, which includes a main gas transmission pipe 2, the gas transmission main pipe 2 is connected with at least two lower gas distribution branch pipes 3 and at least two upper gas distribution branch pipes 4, and the exhaust gas enters the pipeline It is divided into two parts, one part enters the pre-mixing nozzle through the lower air distribution branch pipe 3, and the entrained part of the air enters the pre-mixing chamber for mixing and then performs pre-mixed combustion; the other part directly enters the top annular nozzle of the gas transmission main pipe 2 through the upper air distribution branch pipe for diffusion combustion. Nozzles 15 ( figure 2 ), the nozzle 15 can be a common nozzle or a Figure 8 , 9 The shown cross-shaped nozzle is provided with spray holes 47 on the upper ends 46 of the four arms 45 of the cross-shaped nozzle, and...

Embodiment 2

[0047] Such as Figure 4-5 shown.

[0048] The difference between the present embodiment and the first embodiment lies in the fixing method of the premixing chamber 5. The first embodiment is connected to the main gas pipeline 2 through a support plate 10, while the premixing chamber of the present embodiment is connected to the lower assembly through the triangular support frame 28. Air bronchus 3 connected ( Figure 4 ),and Figure 4 The schematic diagram of the matching burner is as follows Figure 5 shown.

Embodiment 3

[0050] Such as Figure 6-7 shown.

[0051] The difference between this embodiment and Embodiments 1 and 2 is that the connection mode between the lower gas distribution branch pipe 3 and the gas transmission main pipe 2 is changed from a horizontal connection to an inclined lower gas distribution pipe 32, 33 connected obliquely. Image 6 The angle of inclination in is 45 degrees, and it can be designed as other angles, such as 30 degrees, 60 degrees, etc., according to actual needs. Image 6 The equivalent schematic is as Figure 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com