Blast furnace gas catalytic combustion equipment and method for pure blast furnace gas burning

A blast furnace gas, catalytic combustion technology, applied in the combustion method, blast furnace, combustion type and other directions, can solve the problems of inability to allocate blast furnace gas, low calorific value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

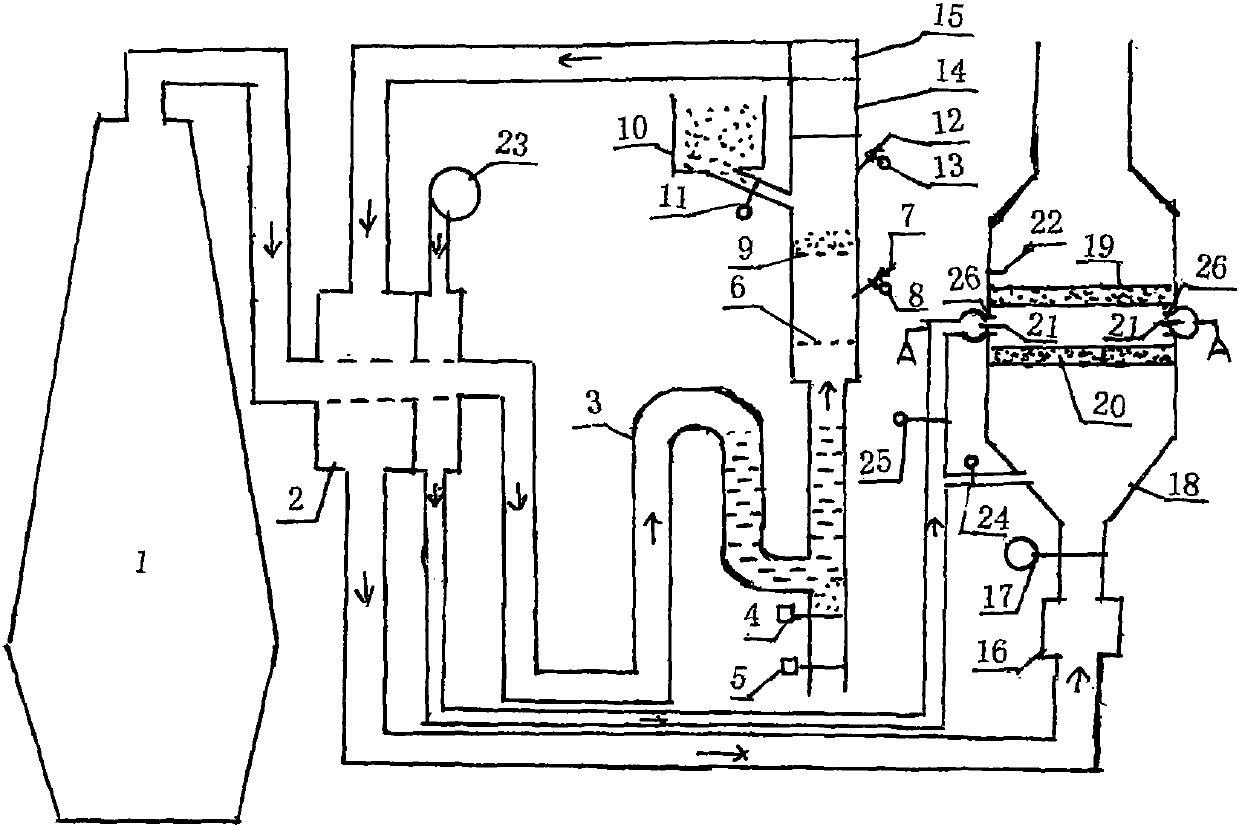

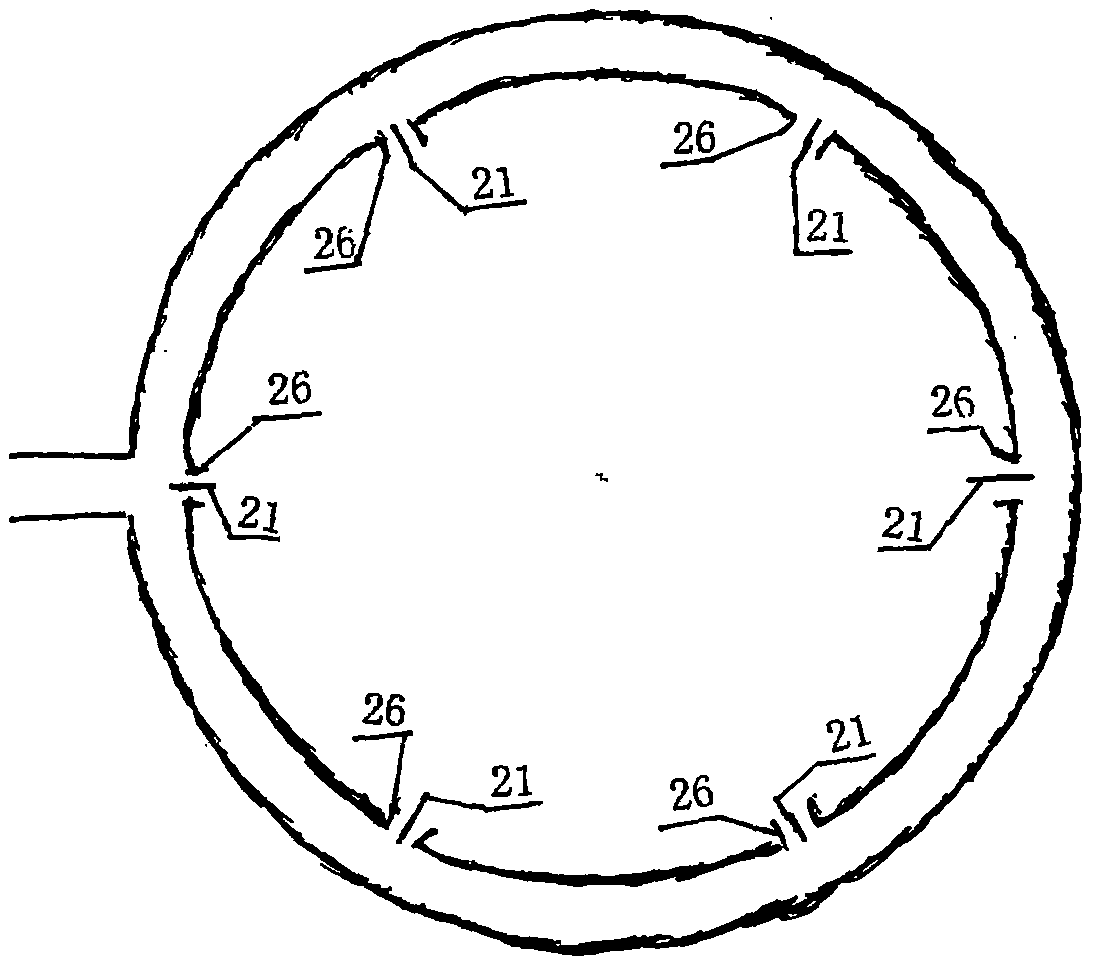

[0009] figure 1 and figure 2 As shown, the structure of the blast furnace gas catalytic combustion equipment of the present invention is as follows: the dirty blast furnace gas that comes out from the top of the ironmaking blast furnace 1 at a temperature between 80 and 150° C. enters the first-stage heat exchange channel of a secondary cooler 2 and The second heat exchange channel is cooled down afterwards. Then go through the slaked lime water wet desulfurizer to remove sulfur dioxide gas and hydrogen chloride gas, and then go through the quicklime powder dry desulfurizer to further remove sulfur dioxide gas and hydrogen chloride gas, and also remove water vapor. Nitric oxide gas is removed through an ammonia gas denitrifier. The structure of the slaked lime water wet desulfurizer is as follows: the thick pipe above the rear section of the double U isolation pipe 3 is equipped with a filter cloth 6 with many small holes. The filter cloth 6 can allow gas to pass through, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com