A closed ground flare system

A ground torch and closed technology, which is applied in the direction of combustion types, lighting and heating equipment, incinerators, etc., can solve the problems of increasing the height of the cylinder, increasing investment costs, and high flame heights, achieving reduced flame heights, low investment costs, and The effect of low cylinder height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

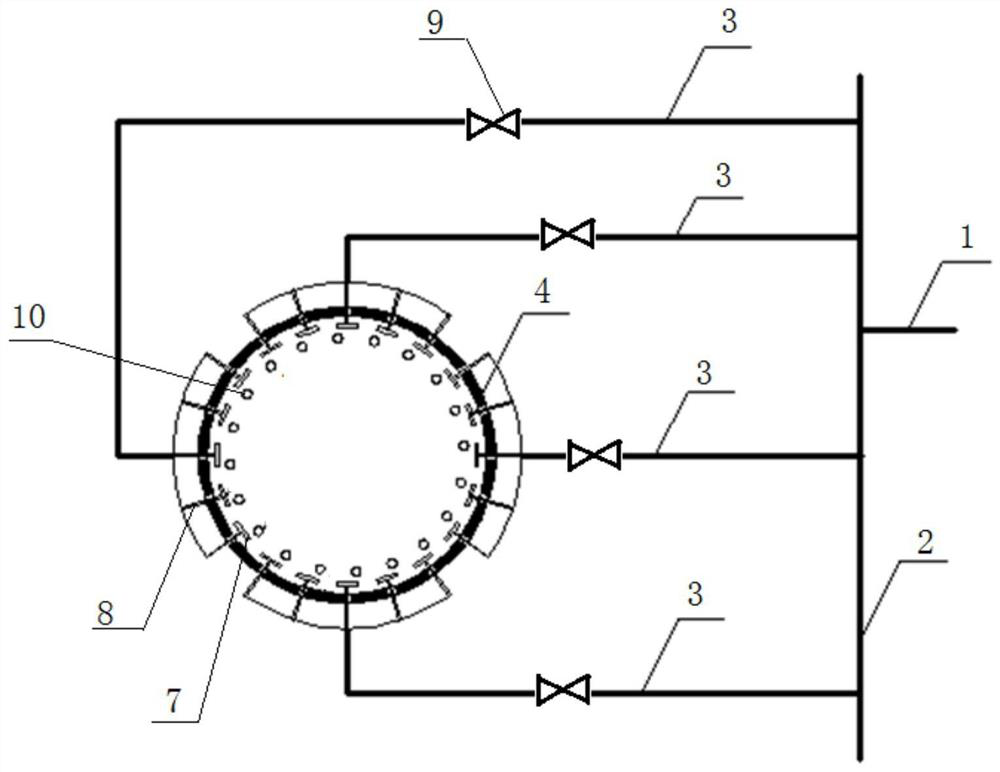

[0034] The present invention provides a closed ground flare system, such as figure 1 As shown in the structure, the torch system reduces the flame length of the burner, improves the combustion efficiency of the burner, reduces the height of the cylinder by means of side burning of the burner, and optimizes the structure of the torch cylinder. The advantage of living alone when in the air.

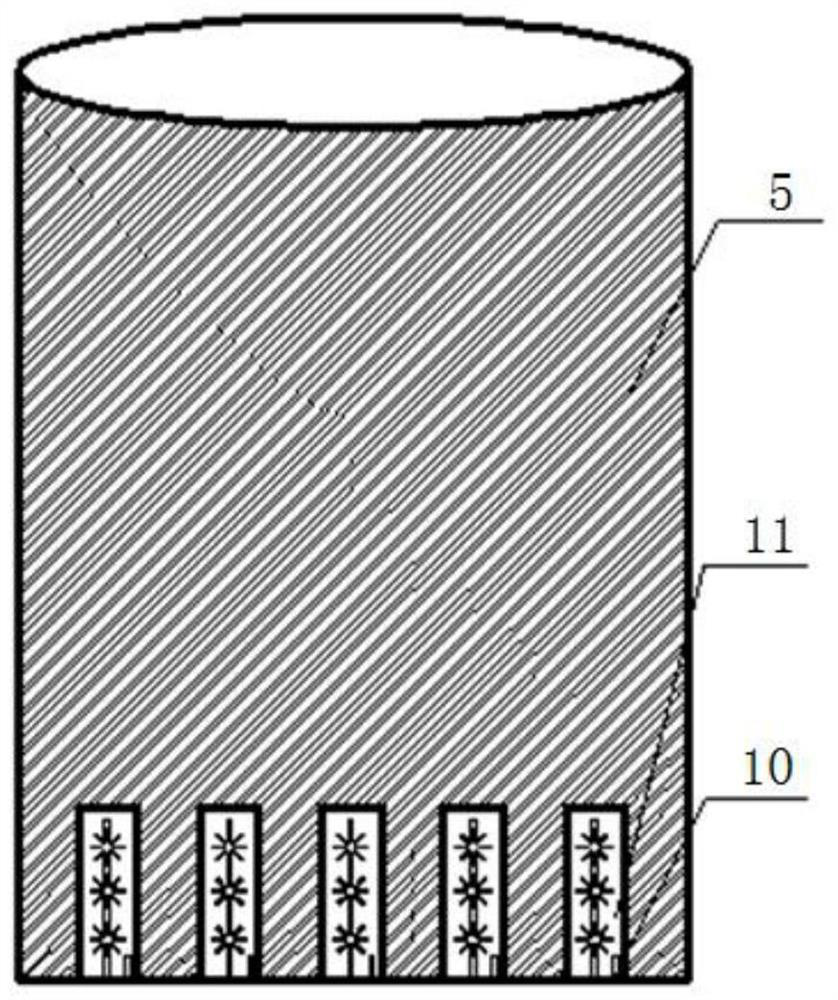

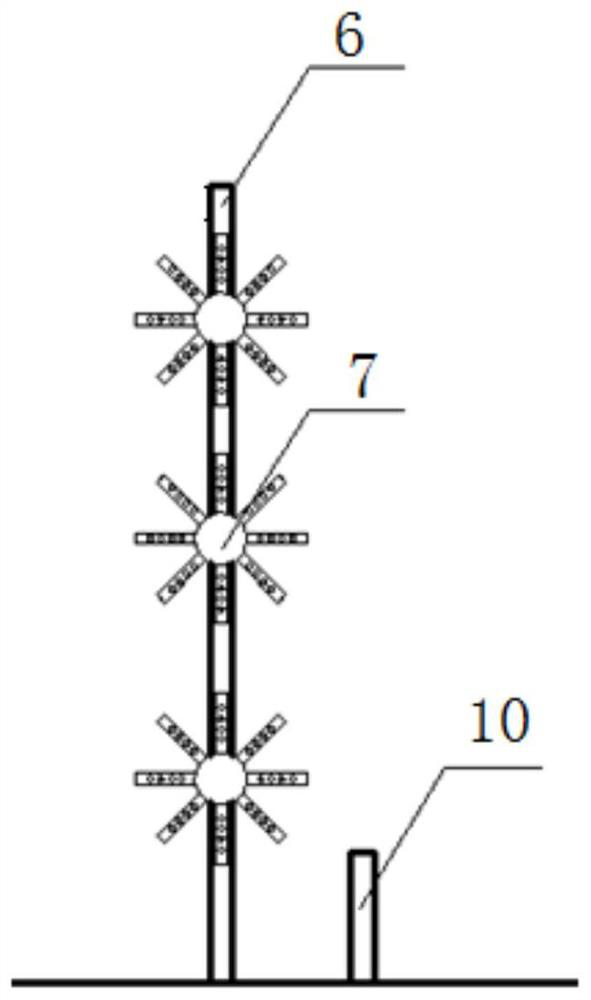

[0035] like figure 1 A closed ground flare system is shown, including a flare gas header 1, a flare gas manifold 2, each grading pipeline 3 and a flare barrel 4, the top of the flare barrel 4 is open, and the flare barrel 4 is made of carbon steel or stainless steel. The material used to build the flare gas combustion chamber. Since the nozzle of the burner 7 is directed towards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com