Novel sludge deep dehydration rinsing agent

A technology of deep dewatering and sludge conditioning, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of large corrosion of ferric chloride, increase and enlargement of sludge filtrate treatment, etc., to improve the effect and increase the strength and combustion value, the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A sludge deep dehydration conditioner is composed of the following components: 30kg of activated carbon powder, 30kg of fly ash, 30kg of quicklime powder, and 10kg of polyaluminum ferric chloride.

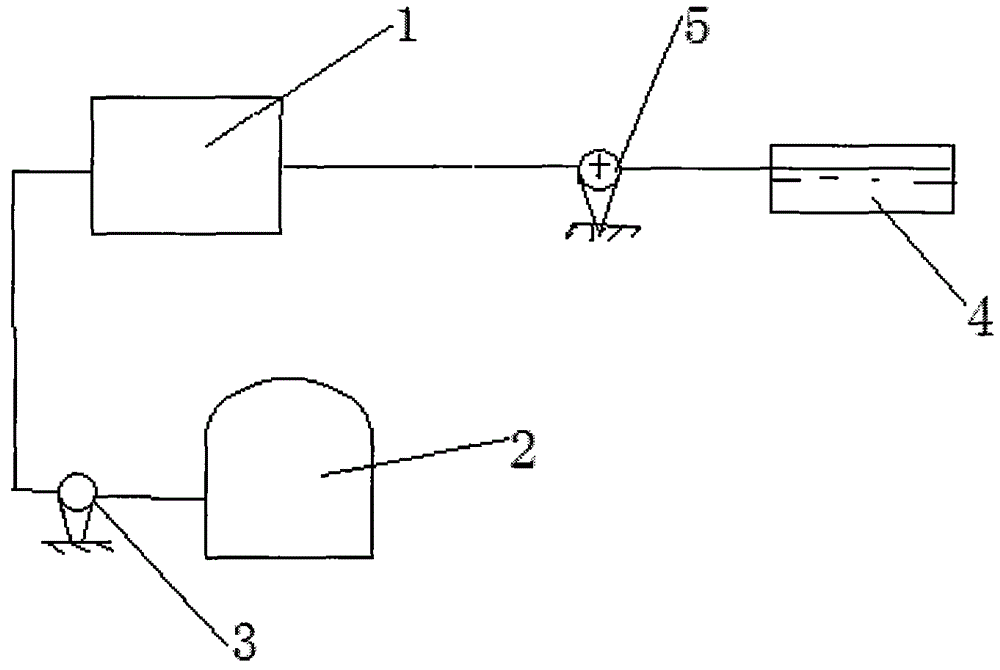

[0016] A method for deep dewatering of sludge (equipment used such as figure 1 shown), follow the steps below:

[0017] (1) Add 30kg of activated carbon powder, 30kg of fly ash, and 30kg of quicklime powder into premixer 1 and mix uniformly to make sludge conditioner A;

[0018] (2) 10kg of polyaluminum ferric chloride is added to the dispensing tank 2, and water is added to form a solution with a mass fraction of 100g / L to make sludge conditioner B;

[0019] (3) Add the sludge conditioner A into 1000kg of water-containing sludge through the premixer and stir evenly, then the sludge conditioner B is pumped into the premixer 1 through the booster pump 3 for mechanical mixing, and then passed through the sludge pump 5 Pump into the sludge deep dehydration equipment 4 for mec...

Embodiment 2

[0021] A sludge deep dehydration conditioner is composed of the following components: 5kg of activated carbon powder, 70kg of fly ash, 5kg of quicklime powder, and 20kg of polyaluminum ferric chloride.

[0022] A method for deep dewatering of sludge (equipment used such as figure 1 shown), follow the steps below:

[0023] (1) Add 5 kg of activated carbon powder, 70 kg of fly ash, and 5 kg of quicklime powder into premixer 1 and mix uniformly to make sludge conditioner A;

[0024] (2) 20kg of polyaluminum ferric chloride is added to the dispensing tank 2, and water is added to form a solution with a mass fraction of 50g / L to make sludge conditioner B;

[0025] (3) Add the sludge conditioner A into 1500kg of water-containing sludge through the premixer and stir evenly, then the sludge conditioner B is pumped into the premixer 1 through the booster pump 3 for mechanical mixing, and then through the sludge pump 5 Pump into the sludge deep dehydration equipment 4 for mechanical d...

Embodiment 3

[0027] A sludge deep dehydration conditioner is composed of the following components: 15kg of activated carbon powder, 62kg of fly ash, 15kg of quicklime powder, and 8kg of polyaluminum ferric chloride.

[0028] A method for deep dewatering of sludge (equipment used such as figure 1 shown), follow the steps below:

[0029] (1) Add 15kg of activated carbon powder, 62kg of fly ash, and 15kg of quicklime powder into premixer 1 and mix uniformly to make sludge conditioner A;

[0030] (2) 8kg of polyaluminum ferric chloride is added to the dispensing tank 2, and water is added to form a solution with a mass fraction of 200g / L to make sludge conditioner B;

[0031] (3) Add the sludge conditioner A into 1500kg of water-containing sludge through the premixer and stir evenly, then the sludge conditioner B is pumped into the premixer 1 through the booster pump 3 for mechanical mixing, and then through the sludge pump 5 Pump into the sludge deep dehydration equipment 4 for mechanical d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com