Manufacturing method of sludge biomass compact briquette fuel

A briquette fuel and manufacturing method technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of incomplete drying of biofuel, high energy consumption, high moisture content, etc., to simplify the pretreatment process, save energy, Strong water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention are described below through specific embodiments. On the premise that there is no conflict with the purpose of the present invention, the embodiments mentioned below and the technical features in the embodiments can be combined with each other.

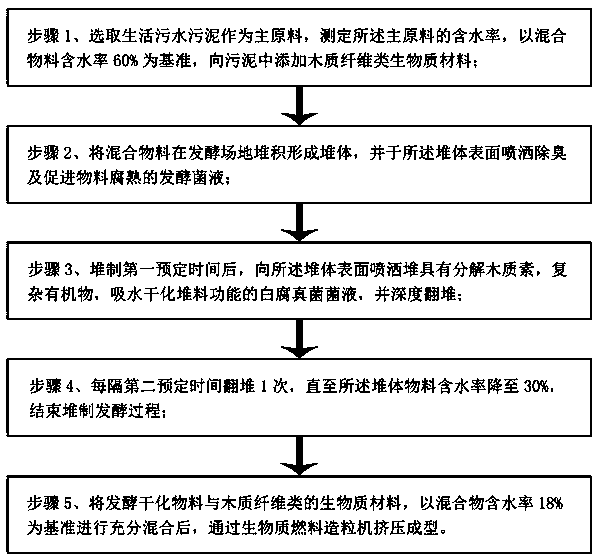

[0031] Such as figure 1 Shown, the manufacture method of a kind of sludge biomass compact briquette fuel of the present invention, wherein, comprises the following steps:

[0032] Step 1, select domestic sewage sludge as the main raw material, measure the moisture content of the main raw material, and add lignocellulosic biomass materials to the sludge based on the moisture content of the mixed material of 60%;

[0033] Step 2. Pile up the mixed material in the fermentation site to form a heap, and spray the fermentation liquid on the surface of the heap to deodorize and promote the material to rot;

[0034] Step 3. After the first scheduled time of composting, spray the white r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com